Note: Do not use caustic soda to clean an aluminum alloy cylinder block.

Attention: when washing the unit in a thermal bath, do not exceed the temperature of 230°C.

Remove all dirt from block surfaces with a solvent or heat bath. Pay special attention to cleanliness:

- surfaces for the installation of gaskets;

- channels for the passage of liquid;

- oil channels;

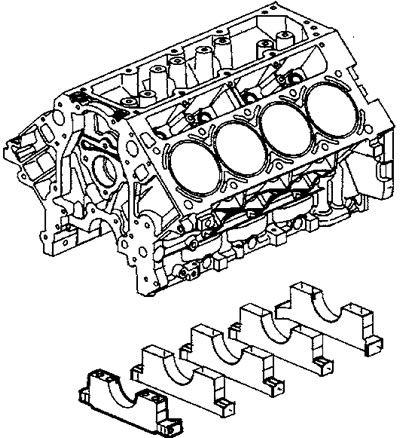

- main bearing caps;

- threaded holes.

Taps of the appropriate size can be used to clean threaded holes.

1. Check:

- the condition of the cylinder walls, look for excessive scratches, scuff marks or annular wear ridges in the stop area of the upper compression ring;

- condition of the cooling jacket, look for cracks;

- the condition of the jumpers of the block for the installation of main bearing caps, look for cracks;

- the condition of the surfaces for the installation of gaskets, seals, o-rings, look for scratches, traces of burnouts and other defects;

- condition of threaded holes.

2. Measure the cylinder diameter to decide whether to move to the next oversize, see specification.

Take measurements in two mutually perpendicular planes and in three places along the height of the cylinder (BDC, TDC, mid-stroke). Based on the measurement results, determine the degree of wear, taper and ovality of the cylinders. If the diameter, taper and ovality are out of tolerance in at least one cylinder, reboring and honing all cylinders.