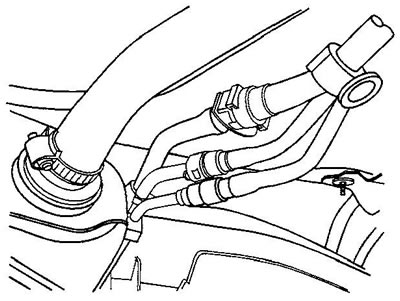

Caution: Before disconnecting the fuel lines, clean the connectors and surrounding areas to prevent dirt from entering the system.

Note: The configuration of the parts is different for different models, please ignore the difference between the actual part and the part shown in the picture.

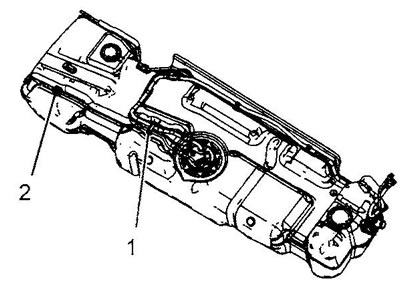

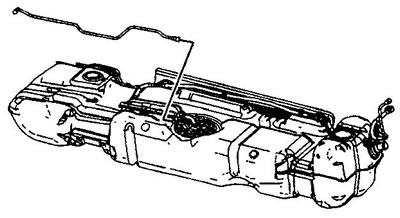

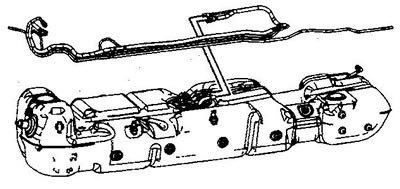

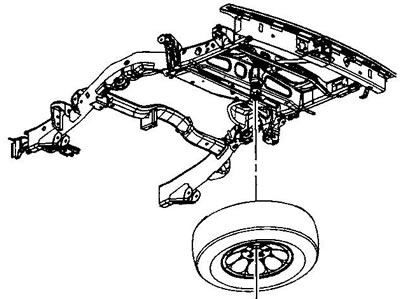

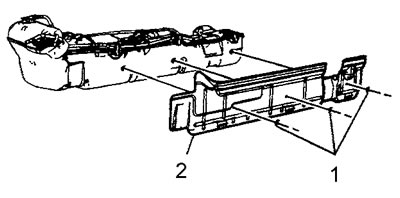

Series 1500

Capacity:

- long base 117 l

- short base 95 l

1. Relieve pressure in the fuel system.

2. Empty the fuel tank.

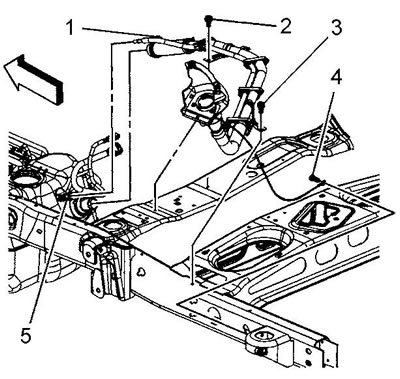

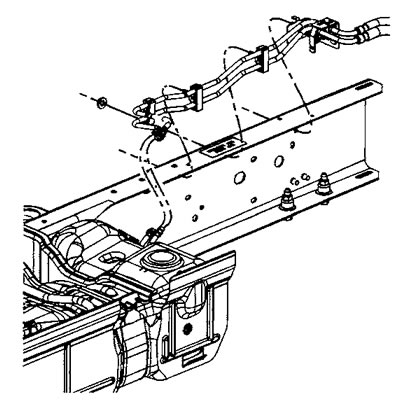

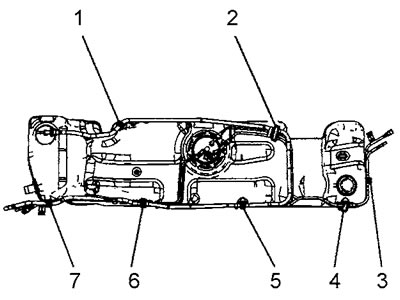

3. Disconnect the connector (5) fuel tank vent hose from the filler pipe.

4. Disconnect the connector from the tank (4) evaporative emission hose.

5. Disconnect the connector (5) fuel supply pipes between the tank and the chassis.

6. Plug all open holes.

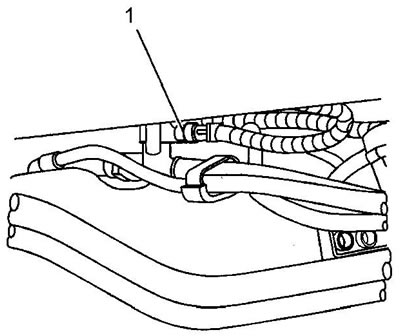

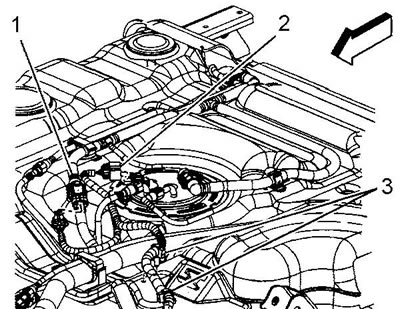

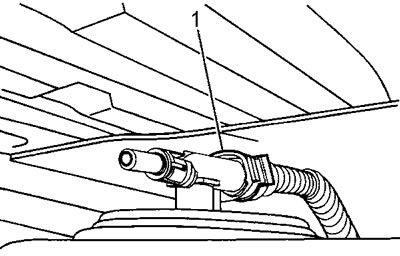

7. Disconnect the hose (1) fuel vapor recovery systems from a vapor accumulator.

8. Plug open holes.

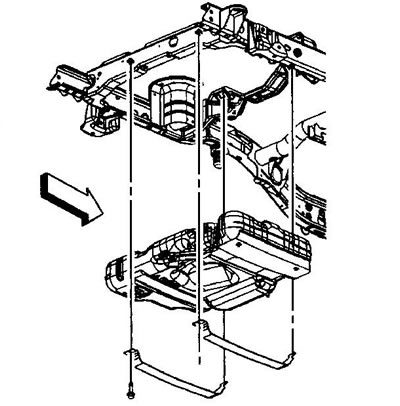

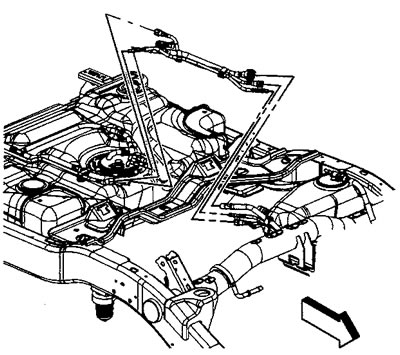

9. Place a jack under the tank.

10. Turn away bolts of slings of fastening of a fuel tank.

11. Remove the fuel tank mounting straps.

12. With the help of an assistant, carefully lower the rear of the fuel tank.

13. Slide the front of the tank off the frame.

14. Lower the tank until you have access to the wire harness connectors.

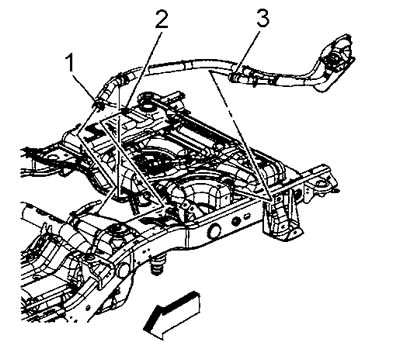

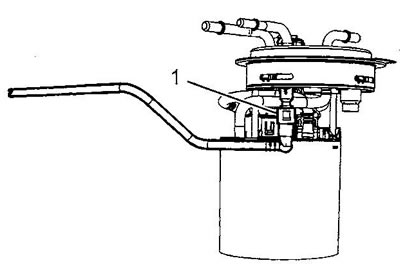

15. Remove the connector holder (1) bundle of wires.

16. Disconnect the connector (1) fuel pump module and fuel pressure sensor.

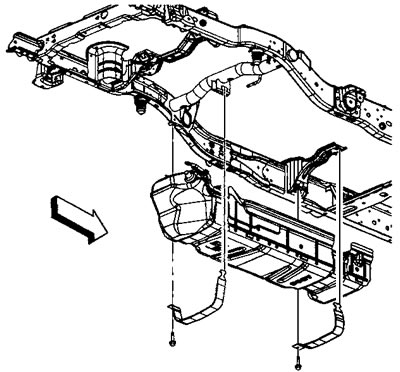

17. Lower the fuel tank completely.

18. With the help of an assistant, transfer the tank to the workbench.

19. If the tank will be replaced, carry out the following operations, otherwise proceed to the installation procedure.

20. Remove the retainer (2) fastening the fuel supply pipe to the tank.

21. Open clip (1) and remove the fuel supply pipe from it.

22. Disconnect the fuel supply pipe from the fuel pump module.

23. Remove the fuel supply pipe.

24. Remove the clips (2) And (3) screens (1) And (4) fuel tank, remove the screens.

25. Release the tubes of the evaporative emission system from the clips (2) And (6).

26. Open clips (1), (3), (4) And (5), free the evaporative emission pipes.

27. Disconnect the EVAP pipes from the fuel pump module and fuel tank vent valve.

28. Remove from a tank of a tube of system of catching of steams of fuel.

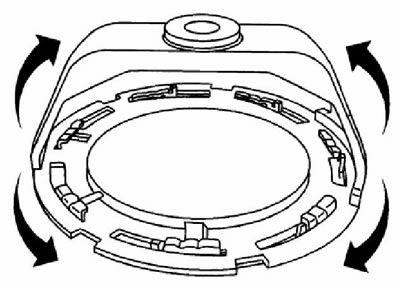

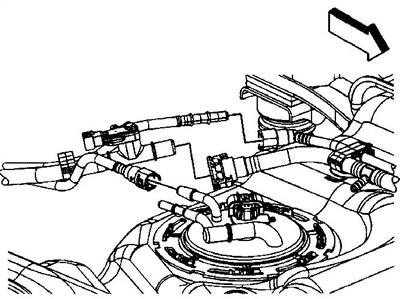

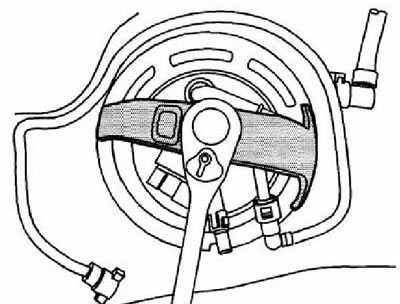

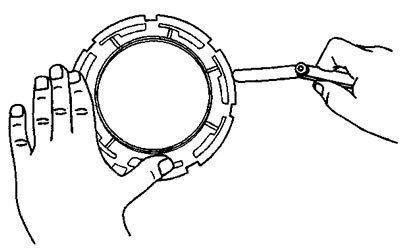

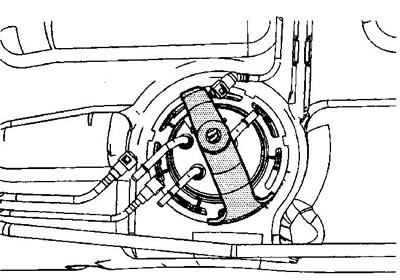

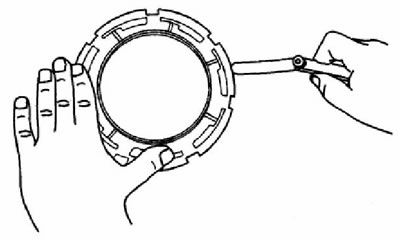

29. Using a special key, unscrew the fuel pump module mounting ring.

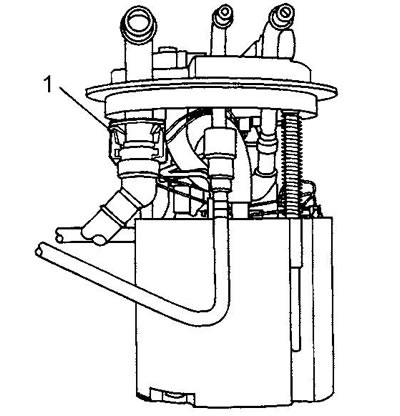

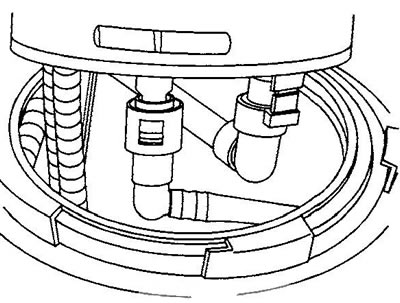

30. Carefully lift the pump module until you have access to the connector (1) under the module cover. Disconnect the connector.

31. Remove the fuel pump module from the fuel tank.

32. Remove and discard the fuel pump module gasket.

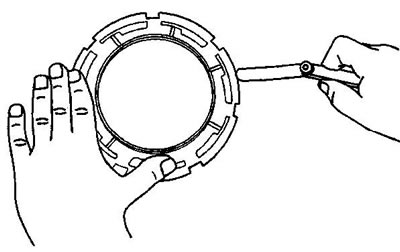

Attention! some fuel pump mounting rings have a stamped mark "DO NOT REUSE" (do not re-install). However, such rings can be installed again if they are not damaged or deformed.

33. Lay the fuel pump module mounting ring on a flat surface. Using a feeler gauge, measure the gap between the ring and the surface at 7 points.

34. If the deformation of the ring is less than 0.41 mm, the ring does not require replacement. Otherwise, replace the ring.

35. Assembly and installation are carried out in the reverse order.

36. After installation, check the system for leaks:

- A) Turn the ignition on for two seconds (do not start the engine).

- b) Switch off the ignition for ten seconds.

- V) Turn on the ignition (do not start the engine).

- G) Inspect the system, look for fuel leaks.

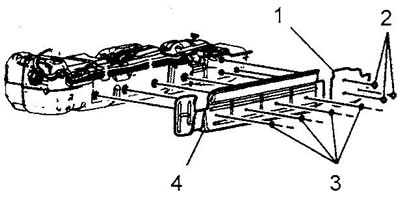

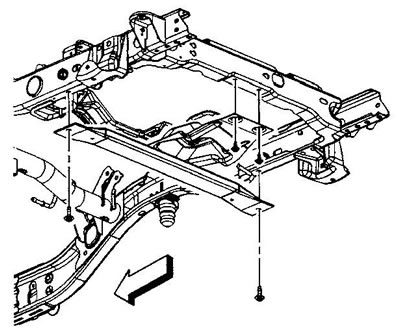

Series 2500 rear tank

Capacity - 43.5 liters

1. Relieve pressure in the fuel system.

2. Remove the spare wheel lock cylinder.

3. Remove the spare wheel.

4. Empty the fuel tank.

5. Remove the rear heat shield of the exhaust system.

6. Turn away bolts of fastening of a cross-beam of the elevator of a spare wheel, remove a cross-beam.

7. Disconnect the rear fuel tank EVAP tube from the fuel vapor accumulator.

8. Disconnect the intermediate EVAP hose from the front tank.

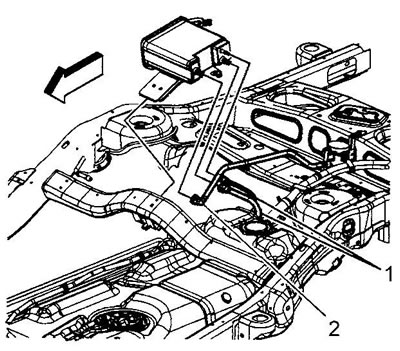

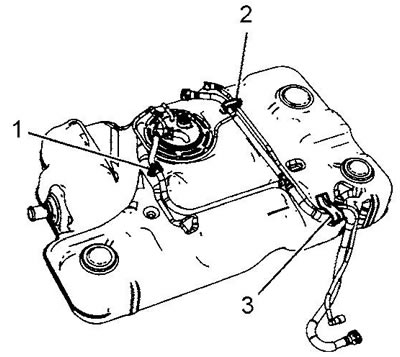

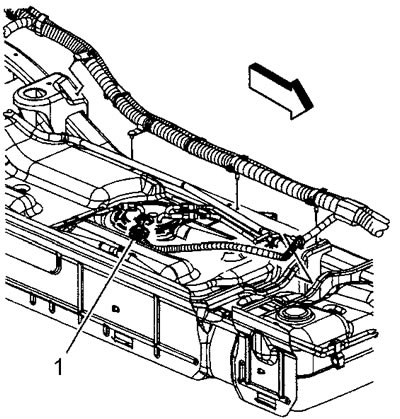

9. Disconnect connector (1) fuel pressure sensor.

10. Place a jack under the fuel tank.

11. Turn away bolts of slings of fastening of a fuel tank.

12. Remove the fuel tank straps.

13. With the help of an assistant, lower the rear tank so that the connectors of the intermediate fuel lines are accessible.

14. Disconnect from a back tank of a tube of fuel system and a tube of system of catching of steams of fuel.

15. Remove tubes of fuel system and tubes of system of catching of steams of fuel.

16. Plug open holes.

17. Disconnect the connector (2) fuel pump module.

18. Fully lower the fuel tank.

19. With the help of an assistant, remove the tank from the jack.

20. When replacing the fuel tank, perform the following operations. Otherwise, proceed with the installation procedure.

21. Remove the tubes of the evaporative emission system from the clip (1).

22. Open clip (2) and remove the tubes of the evaporative emission system from it.

23. Remove the tube of the evaporative emission system from the clip (3).

24. Disconnect the EVAP tubes from the fuel pump module.

25. Remove the EVAP pipe from the fuel tank.

26. Using a special key, unscrew the fuel pump module mounting ring.

27. Carefully lift the fuel pump module to access the tubing connector under the module cover.

28. Remove the fuel pump module.

29. Remove and discard the fuel pump module gasket.

Attention! some fuel pump mounting rings have a stamped mark "DO NOT REUSE" (do not re-install). However, such rings can be installed again if they are not damaged or deformed.

30. Lay the fuel pump module mounting ring on a flat surface. Using a feeler gauge, measure the gap between the ring and the surface at 7 points.

31. If the deformation of the ring is less than 0.41 mm, the ring does not require replacement. Otherwise, replace the ring.

32. Assembly and installation are carried out in the reverse order.

33. After installation, check the system for leaks:

- A) Turn the ignition on for two seconds (do not start the engine).

- b) Switch off the ignition for 10 seconds.

- V) Turn on the ignition (do not start the engine).

- G) Inspect the system, look for fuel leaks.

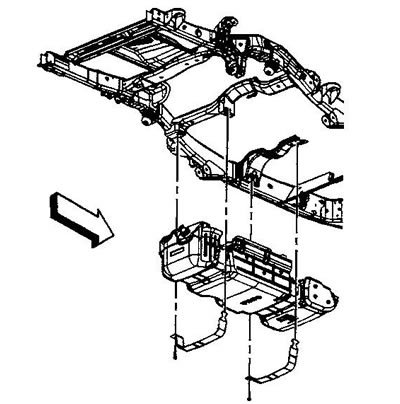

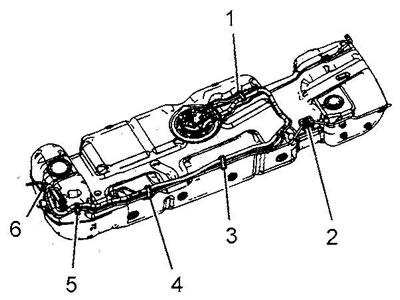

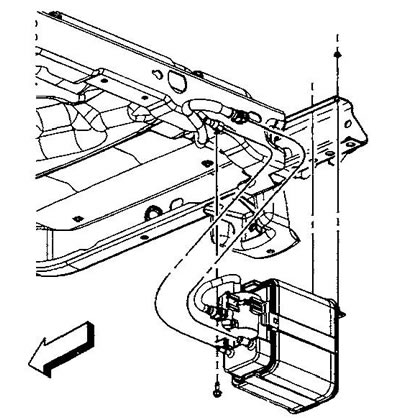

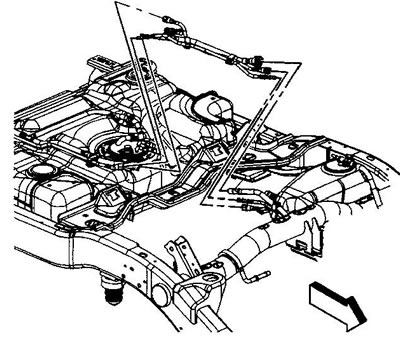

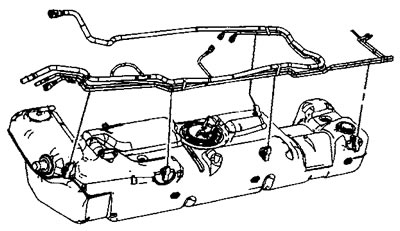

Series 2500, front tank

Capacity - 98.5 liters

1. Relieve pressure in the fuel system.

2. Empty the fuel tank.

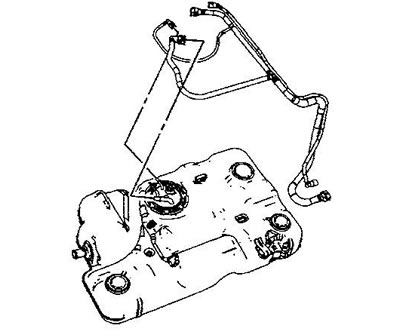

3. Disconnect the connector (2) evaporative emission pipes (filler neck) from the fuel tank vent valve.

4. Disconnect the connector (1) pipes of the fuel vapor recovery system from the fuel tank ventilation valve.

5. Disconnect from a fuel tank of a tube of fuel system and a tube of system of catching of steams of fuel.

6. On the side of the fuel tank, open the intermediate fuel line support clip.

7. Disconnect the intermediate fuel supply pipes and evaporative emission systems from the front tank pipes.

8. Plug open holes.

9. Place a jack under the fuel tank.

10. Turn away bolts of slings of fastening of a fuel tank.

11. Remove the fuel tank mounting straps.

Attention: when lowering the fuel tank, make sure that the fuel pipes do not hit anything.

12. With the help of an assistant, carefully lower the fuel tank until the wire harness connectors are accessible.

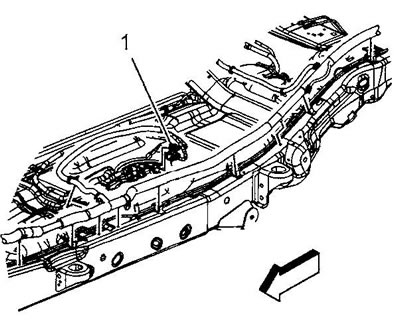

13. Remove the harness connector holder.

14. Disconnect the connector (1) fuel pump module.

15. Lower the fuel tank completely.

16. Lay the fuel tank on the workbench.

17. When replacing the fuel tank, perform the following operations. Otherwise, proceed with the installation procedure.

18. Remove the clips (1) fuel tank screen, remove the screen (2).

19. Release the tube of the evaporative emission system from the clip (1).

20. Open clips (2-7) and free the fuel system pipes and evaporative emission systems.

21. Disconnect the fuel system pipes and evaporative emission systems from the fuel pump module.

22. Remove from a tank of a tube of fuel system and system of catching of steams of fuel.

23. Using a special key, unscrew the fuel pump module mounting ring.

24. Carefully lift the pump module until you have access to the tubing connector (1) under the module cover.

25. Remove the fuel pump module.

26. Remove and discard the fuel pump module gasket.

Attention! some fuel pump mounting rings have a stamped mark "DO NOT REUSE" (do not re-install). However, such rings can be installed again if they are not damaged or deformed.

27. Lay the fuel pump module mounting ring on a flat surface. Using a feeler gauge, measure the gap between the ring and the surface at 7 points.

28. If the deformation of the ring is less than 0.41 mm, the ring does not require replacement. Otherwise, replace the ring.

29. Assembly and installation are carried out in the reverse order.

30. After installation, check the system for leaks:

- A) Turn the ignition on for two seconds (do not start the engine).

- b) Switch off the ignition for ten seconds.

- V) Turn on the ignition (do not start the engine).

- G) Inspect the system, look for fuel leaks.