Withdrawal

Early models

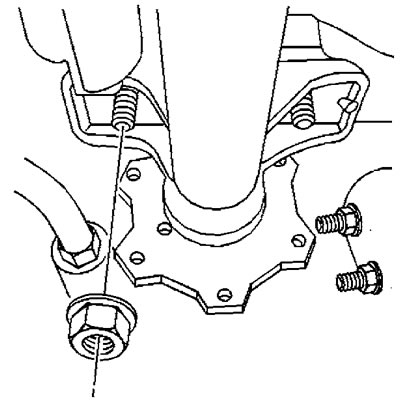

1. Remove the inner nuts and washers securing the front axle beam to the frame bracket.

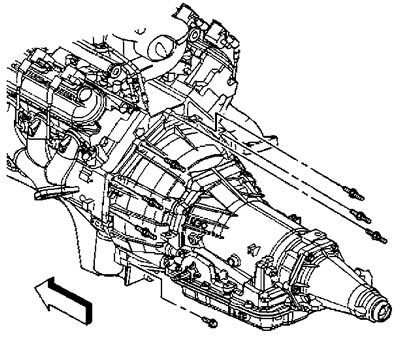

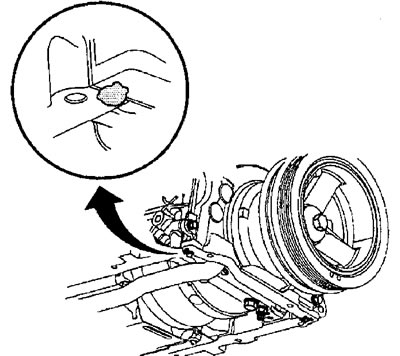

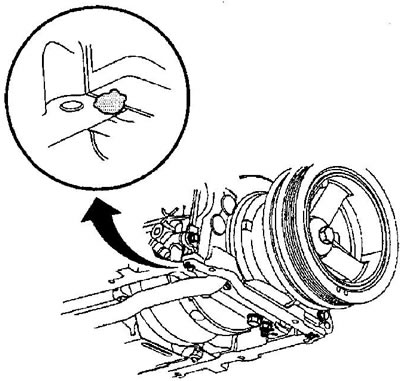

2. Place a jack under the axle beam.

3. Turn away the bottom bolt of fastening of a case of the main transfer of the forward bridge.

4. Turn away the top bolt of fastening of a case of the main transfer of the forward bridge.

5. Lower the front axle.

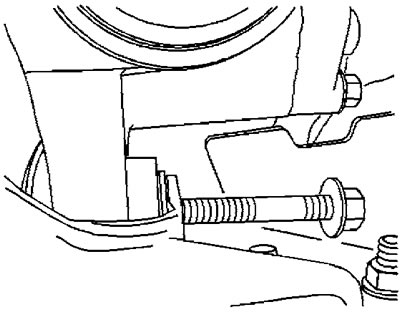

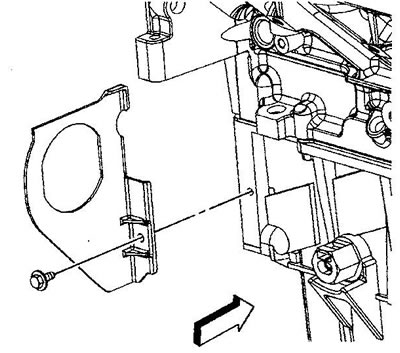

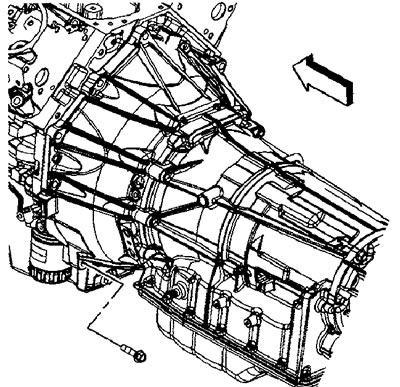

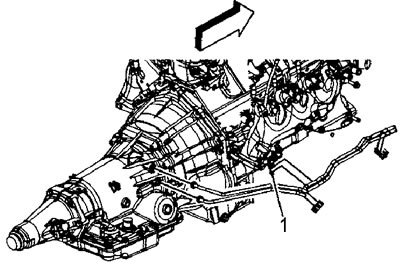

6. Turn away a bolt of fastening of a cover of automatic transmission.

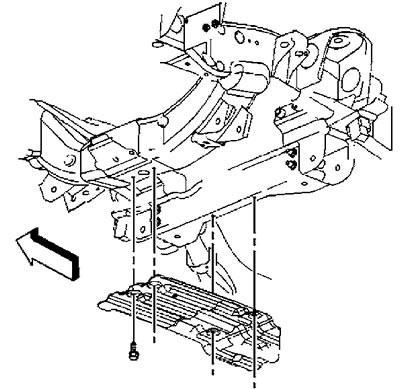

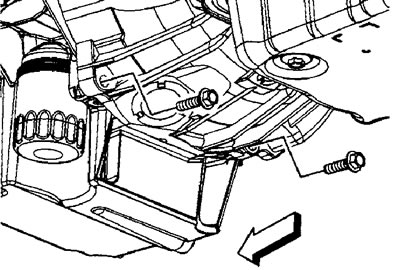

7. Turn away bolts of fastening of protection of the oil pallet (if installed).

8. Remove the oil pan protection.

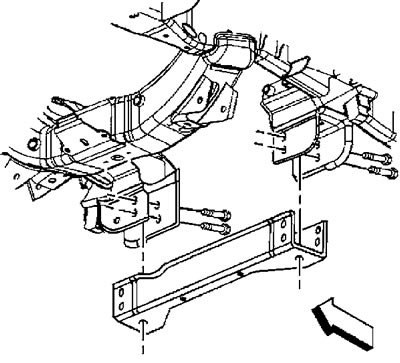

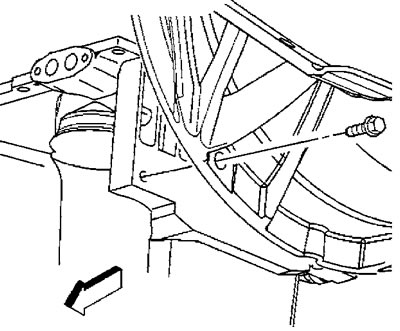

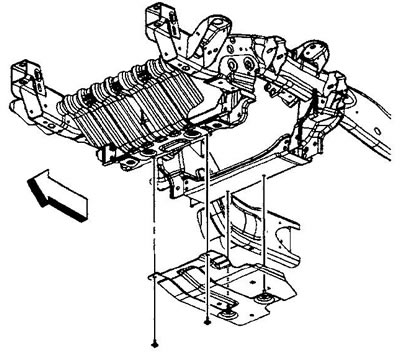

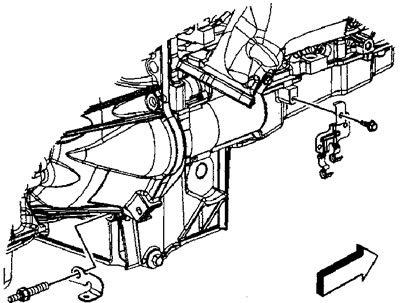

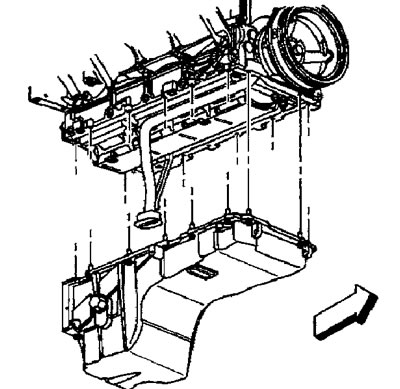

9. Turn away bolts of fastening of a crossbar.

10. Remove the cross member.

11. Turn away a bolt of fastening of a cover of automatic transmission, remove a cover.

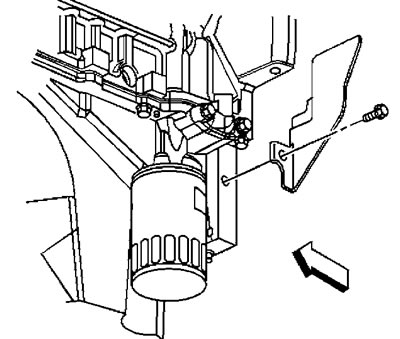

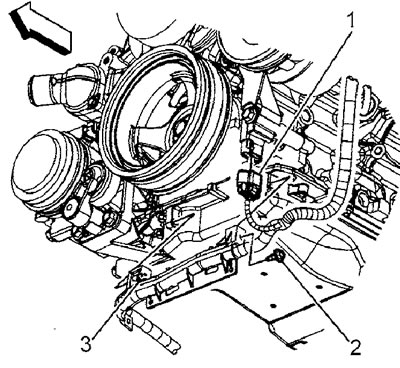

12. Drain the engine oil and remove the oil filter.

13. Replace the drain plug, tighten the plug by hand.

14. If automatic transmission 4L60-E is installed, unscrew the right bolt and the automatic transmission mounting bolt-stud.

15. Turn away the left lower bolt of fastening of automatic transmission.

16. If automatic transmission 4L80-E is installed, unscrew the torque converter cover bolts.

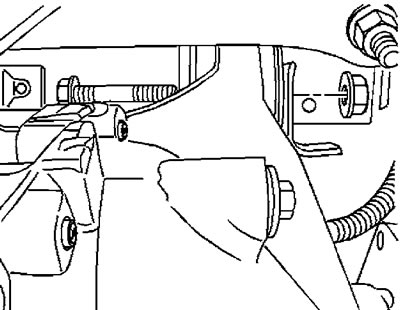

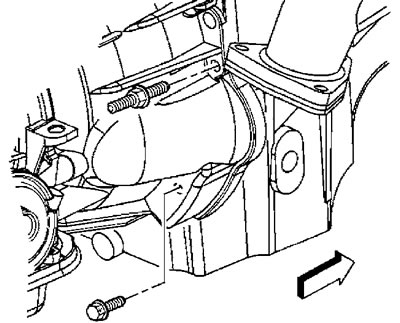

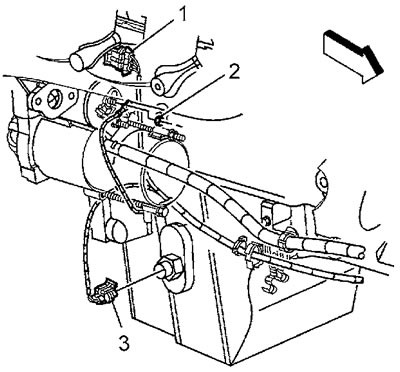

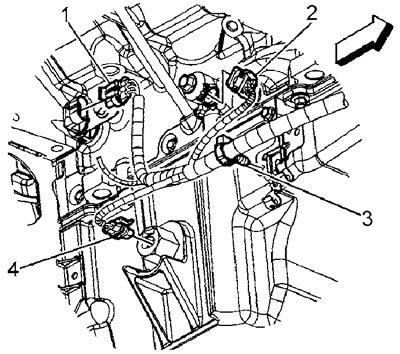

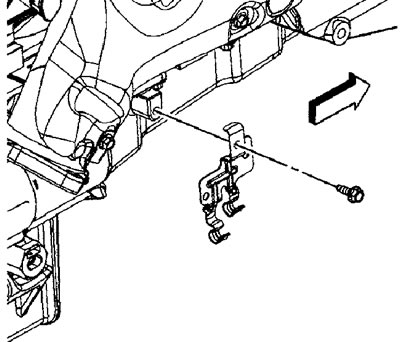

17. Disconnect the connector (3) oil level sensor.

18. Turn away a bolt of the channel of a cable of the storage battery.

19. Pull the cable channel fixing pin out of the oil pan.

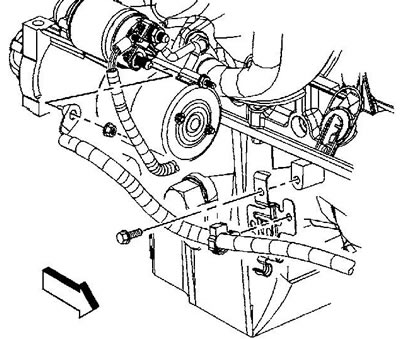

20. Disconnect the battery cable and cable support clip from the starter

21. Remove the engine oil cooler pipes from the battery cable clip.

22. Turn away a bolt of fastening and remove a clip of a cable of the storage battery.

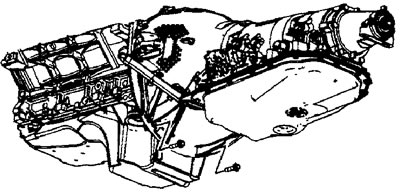

23. Turn away bolts of fastening of the oil pallet.

24. Remove the oil pan.

Attention: do not allow dirt to enter the engine oil line, install plugs on open holes.

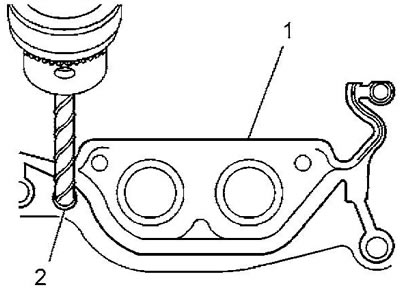

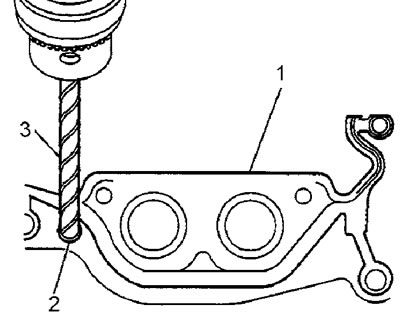

25. If the pan gasket needs to be replaced, drill out the rivets (2) fastening the gasket to the pallet.

26. Remove the gasket (1), discard the gasket and rivets.

Note: It is not necessary to rivet a new gasket to the pallet.

Later models

1. Raise the vehicle and place the safety stands under the frame.

2. On 1500 series models, remove the oil pan guard mounting bolts and remove the guard.

3. On 2500 series models, loosen the two rear and two front bolts securing the oil pan guard and remove the guard.

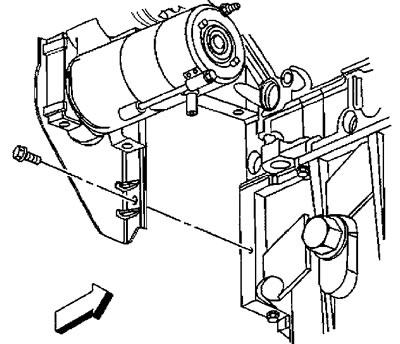

4. Remove the front axle final drive housing.

5. Turn away fixture of a steering rack and hang up a rack on a wire.

6. Place a container under the oil pan drain plug to collect the oil.

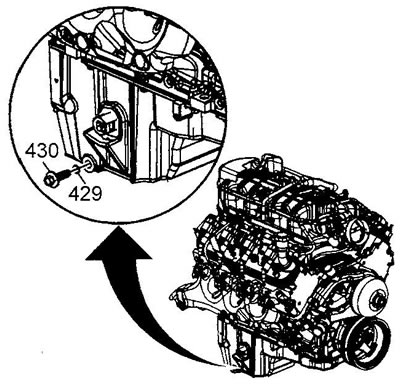

7. Remove the drain plug (430).

8. Drain the oil pan completely.

9. Install and tighten the drain plug by hand.

10. Place a container under the oil filter to collect the oil.

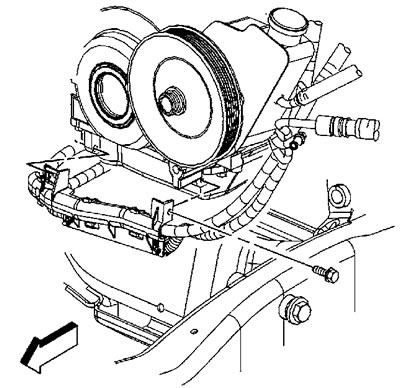

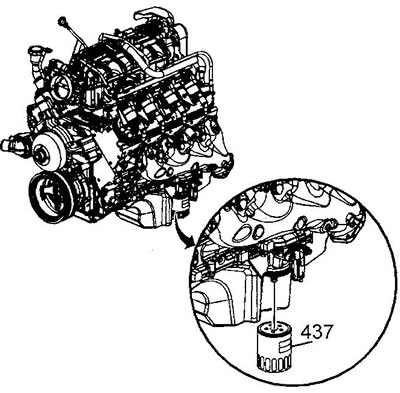

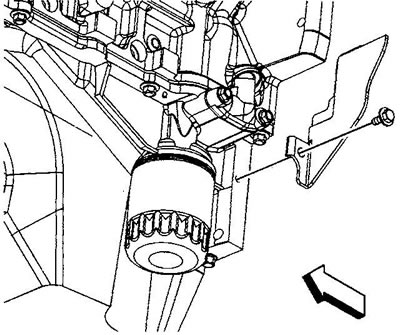

11. Unscrew the oil filter (437).

12. Drain the oil.

13. Install the oil filter and tighten it by hand.

14. Turn away a bolt of fastening of the right cover of automatic transmission.

15. Turn away a bolt of fastening of the left cover of automatic transmission.

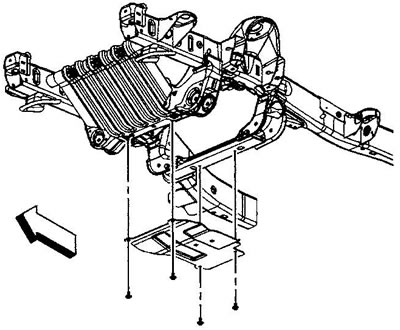

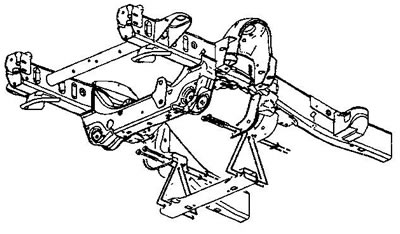

16. Turn away fixture of a cross-member, remove a cross-member.

1500 Series Crossbar Shown

17. Turn away two lower bolts of fastening of automatic transmission.

To point 17, automatic transmission 4L60-E/4L70-E |

To point 17, automatic transmission 4L80-E |

18. On models with automatic transmission 6L80-E, unscrew the lower left and right automatic transmission mounting bolts.

Automatic transmission 6L80-E, left bolt |

Automatic transmission 6L80-E, right bolt |

19. Disconnect the connector (4) oil level sensor.

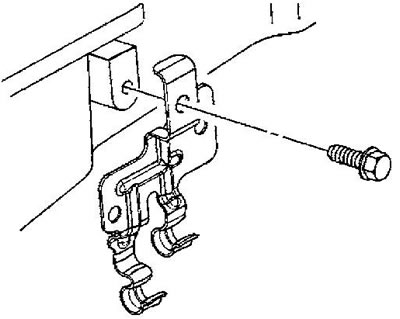

20. Remove clip (3) supporting the engine wire harness with the oil cooler tube bracket.

21. Remove the bolt (2) battery cable channel.

22. Take out your finger (3) channel from the oil pan.

23. Release the automatic transmission fluid cooler tubes from the oil pan clip.

Shown automatic transmission 4L60-E/4L70-E

24. Turn away a bolt of fastening of a clip of tubes of a cooler to the oil pallet and remove a clip.

25. Turn away bolts of fastening of the oil pallet.

26. Remove the oil pan.

27. If an old pallet will be installed, proceed with the installation. Otherwise, drill out the rivets (2) fixing the pan gasket, remove the gasket (1), discard the gasket and rivets.

Note: It is not necessary to rivet a new gasket to the pallet.

Installation

Attention: the position of the hole for the lower bolts of the automatic transmission is critical for the rigidity of the alignment of the power unit. It is important that the rear of the oil pan does not protrude beyond the rear plane of the cylinder block anywhere.

Early models

1. If removed, install a new oil pan gasket.

2. Apply a bead of sealant with a diameter of approximately 5 mm and a length of 20 mm to the joints of the planes of the block and engine covers. The protrusion of the gasket of the front or rear cover can not be cut off.

3. Install the pan and gasket on the engine with two bolts.

Attention: Align the holes in the oil line of the cylinder block with the holes in the oil pan gasket.

4. Install the remaining pan mounting bolts.

5. Tighten the sump bolts by hand.

6. If automatic transmission 4L80-E is installed, install and hand-tighten the torque converter cover bolts.

7. If automatic transmission 4L80-E is installed, install the bolt and bolt-stud securing the right side of the automatic transmission.

8. Install the lower left automatic transmission mounting bolt. Tighten:

- A) bolts securing the pan to the front cover. Tightening torque 25 Nm.

- b) bolts securing the pan to the rear cover. Tightening torque 12 Nm.

- V) automatic transmission mounting bolts and torque converter covers. Tightening torque 50 Nm.

9. Install the battery cable clip on the pallet, tighten the fastening bolt. Tightening torque 9 Nm.

10. Attach the engine oil cooler pipes to the battery cable clip.

11. Fasten the battery cable to the starter, fasten the cable to the clip.

12. Insert the battery cable channel fixing pin into the oil pan.

13. Tighten the cable channel mounting bolt. Tightening torque 12 Nm.

14. Connect a socket of the gauge of level of engine oil.

15. Install the automatic transmission cover, tighten the mounting bolt. Tightening torque 12 Nm.

16. Install the cross member. Tighten the cross member mounting bolts. Tightening torque 100 Nm.

17. Install the oil pan guard. Tighten the protection mounting bolts. Tightening torque 20 Nm.

18. Install the automatic transmission cover, tighten the cover bolts. Tightening torque 12 Nm.

19. Raise the front axle to the installation position.

20. Install the upper bolt and nut of the final drive housing. Tighten the nut by hand.

21. Install the bottom bolt and nut of the final drive housing. Tighten the top and bottom bolts. Tightening torque 100 Nm.

23. Screw nuts of fastening of a beam of the forward bridge, tighten nuts. Tightening torque 100 Nm.

24. Remove the jack from under the bridge beam.

25. Tighten the drain plug of the pan, install the oil filter and fill in engine oil.

Later models

1. If removed, install a new oil pan gasket.

2. Apply a bead of sealant with a diameter of approximately 5 mm and a length of 20 mm to the joints of the planes of the block and engine covers. The protrusion of the gasket of the front or rear cover can not be cut off.

3. Install one sump bolt into the sump to secure the gasket.

4. Install the pallet in place and hand-tighten the mounting bolts.

5. Install the lower automatic transmission mounting bolts, tighten the bolts by hand.

6. Tighten the bolts securing the pan to the front cover. Tightening torque 25 Nm.

7. Tighten the bolts securing the tray to the rear cover. Tightening torque 12 Nm.

8. Tighten bolts of fastening of the pallet to the block of cylinders. Tightening torque 50 Nm.

9. Install the coolant pipe support clip on the pallet, tighten the fastening bolt. Tightening torque 9 Nm.

10. Fix tubes of a cooler of a working liquid in a clip.

11. Insert the fastening pin of the battery cable channel into the pan, tighten the channel fastening bolt. Tightening torque 12 Nm.

12. Connect the oil level sensor connector.

13. Attach the engine wire harness to the oil cooler tube clip.

14. Before installing the cross member, remove the remnants of old glue from the frame and cross member, clean the threads of the fastening bolts and nuts, apply locking glue to the thread of the bolts.

15. Install the cross member and tighten the mounting bolts and nuts. Tightening torque: 2500 series 120 Nm, 1500 series 100 Nm.

16. Install the left automatic transmission cover. Tighten the mounting bolt. Tightening torque 12 Nm.

17. Install the right automatic transmission cover. Tighten the mounting bolt. Tightening torque 12 Nm.

18. Install a new oil filter:

- A) Lubricate the filter o-ring with engine oil.

- b) Tighten the filter. Tightening torque 30 Nm.

19. Tighten the oil pan drain plug. Tightening torque 25 Nm.

20. Install the front axle final drive housing.

21. Reinstall the steering rack. Tighten the mounting bolts. Tightening torque: left side bolts 200 Nm, right side bolts 100 Nm.

22. Install motor protection. Tighten the mounting bolts. Tightening torque 28 Nm.

23. Lower the car.

24. Fill the engine with engine oil. Start the engine and check for oil leaks.