Disassembly

Note: Brake caliper repair is shown using a 2500 series front caliper as an example.

1. Remove the brake caliper.

2. Drain the brake fluid from the caliper.

Caution: When extruding the piston with compressed air, do not catch the piston with your hand, otherwise injury will result.

Attention: Brake caliper pistons are made of phenolic plastic. The pistons have stainless steel inserts that seem to come into contact with the brake pads.

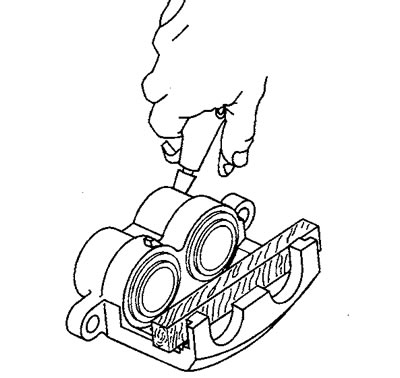

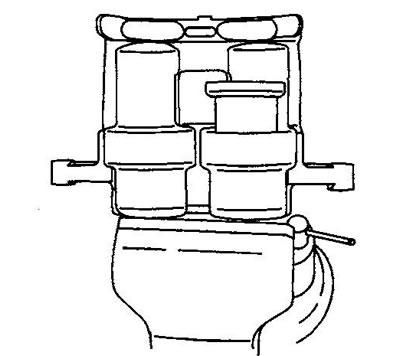

3. Secure the caliper in a vise.

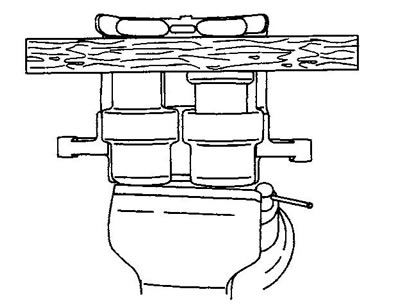

4. Lay a piece of wood between the pistons and the outer caliper bridge.

5. Cover the caliper with a towel.

6. Apply compressed air to the brake hose mounting hole, squeeze out the pistons.

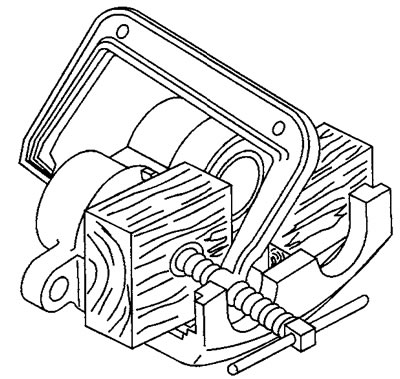

7. If one of the pistons cannot be removed in this way, perform the following operations.

- A) Install the extruded piston in place.

- b) Using a clamp and a small piece of wood, slide the piston into the caliper halfway down the length of the piston.

- V) Place the second plate in front of the other piston.

- G) Cover the caliper with a towel.

- d) Apply compressed air to the brake hose mounting hole, squeeze out the piston.

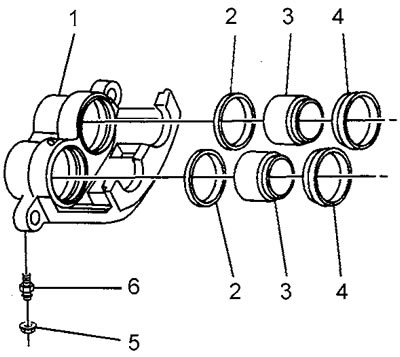

8. Remove pistons (3) from the caliper holes.

9. Remove the anthers from the caliper (4). Do not scratch the anther seat in the caliper.

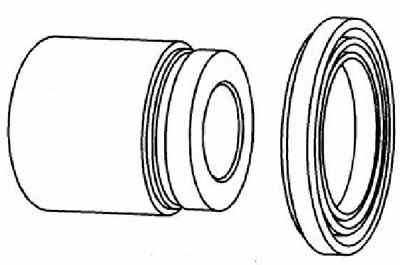

10. Use a plastic or wooden rod to remove the piston seals from the caliper (2). _

11. Remove the cover (5) drain screw (6).

12. Remove the drain screw.

13. Wash all metal parts with denatured alcohol. Dry parts with compressed air. Blow through the channels of the caliper.

14. Replace pistons or caliper if:

- there are scratches or scuffs in the caliper and / or on the piston;

- there is corrosion or pitting in the caliper holes;

- piston is damaged.

Assembly

Attention: when assembling the brake caliper, lubricate the parts to be installed with clean brake fluid immediately before installation. This will prevent accidental dirt ingress.

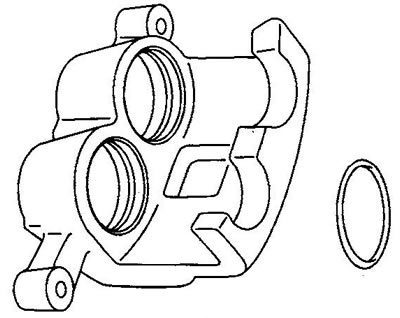

1. Lubricate the piston, piston seal, and piston bore in the caliper with brake fluid (DOT-3 grade fluid).

2. Install the rectangular piston seal into the groove in the bore in the caliper.

3. If the seal is curled, straighten it.

4. Install the boot on the piston so that the fold of the boot is directed towards the caliper body.

5. Install the piston in the caliper (without distortion) and slide the boot into the groove in the caliper bore.

6. Place a piece of wood on the piston.

7. Use even hand pressure to push the piston into the caliper.

8. Remove the plate.

9. Install the drain screw into the caliper body. Tightening torque 72 Nm.

10. Install the drain screw cap.

11. Install the caliper on the car.