If pad replacement is necessary, replace pads on all wheels of the same axle.

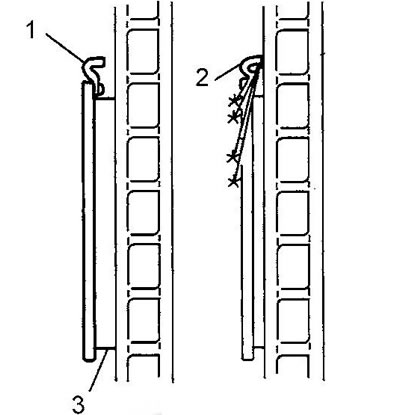

Check pad thickness (3) from both ends. The highest rate of wear usually occurs at the trailing edge of the pad.

Brake pad wear should be approximately equal on both wheels of the same axle.

Brake pads equipped with a wear sensor (1). When the pads wear to the minimum allowable thickness, the wear sensor comes into contact with the disc (2), generating a high frequency sound.

The brake pad must be replaced with a friction layer thickness of 0.76 mm.

Remove the brake caliper. Inspect the friction surfaces of the inner and outer brake pads. The pads should wear about the same. Place the pads with the friction surfaces facing each other. Measure the gap between the surfaces. If the gap is greater than 0.13mm (approximately in the middle of the friction surface), replace pads.

Check that the brake pad shims are in place and not damaged or heavily rusted.

Replace the pads when the friction material is detached from the base, in the presence of cracks and other defects.