Withdrawal

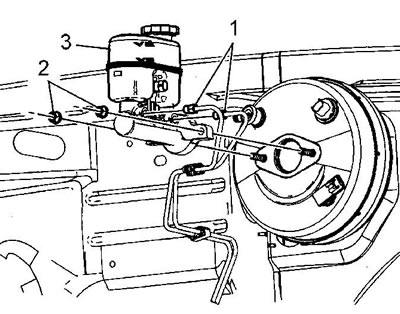

Models with a vacuum brake booster |

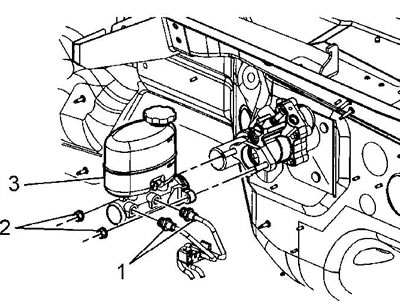

Models with hydraulic brake booster |

1. Using a siphon, pump out the brake fluid from the reservoir of the master brake cylinder.

2. Loosen the nuts (1) fixing the brake pipes to the brake cylinder body. Plug open holes. Tightening torque 25 Nm.

3. Disconnect the brake fluid level sensor connector.

4. Loosen the nuts (2) fixing the brake master cylinder. Tightening torque 33 Nm.

5. Remove the main brake cylinder.

Installation

6. Installation is carried out in the reverse order. Bleed the brake system after installation.

Pumping

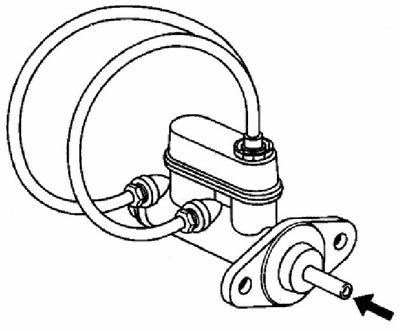

1. Secure the master cylinder to its flange in a vise so that the back of the primary piston is accessible.

2. Remove the reservoir cap of the main brake cylinder.

3. Install flexible transparent hoses at the places where the brake pipes are connected, insert the hoses into the reservoir of the main brake cylinder.

4. Fill the master cylinder reservoir about half way with clean brake fluid (DOT-3).

5. During pumping, the ends of the hoses must be under the level of the brake fluid.

6. Using a rounded rod, depress and release the primary piston. The piston stroke should be approximately 25 mm. Watch the fluid flow through the hoses. As air is removed, the pressure on the piston will increase, and the piston stroke will decrease.

7. Continue pumping until air is completely removed from the cylinder.

8. Remove transparent hoses.

9. Establish a cover of a reservoir of the main brake cylinder.

10. Muffle places of connection of brake tubes.

11. Remove the master cylinder from the vise.