2. Remove the differential cover and drain the oil.

Conventional differential

3. Turn away a lock bolt and remove the shaft of conducted gear wheels of differential (see photo).

4. Working with an assistant, remove the lock U-shaped washer from the groove on the inside of the axle shaft by pressing on the flange of the axle shaft (see photo).

5. Rotate the differential to access the bolt. While holding the differential driven gear shaft, remove the locking mechanism bolt.

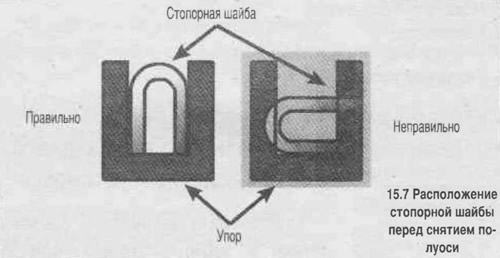

6. Pull out part of the differential driven gear shaft. Rotate the differential until the pin contacts the differential housing to provide enough clearance to access the lock washer (see photo).

7. Use a screwdriver to turn the lock washer as shown in the photo.

8. Get a lock washer. Do the same for the second axle.

All models

9. Get a semiaxis, having taken measures not to damage an epiploon. On some cars, a thrust washer is provided in the differential, take measures so that this washer does not fall out when removing the axle shaft.

10. Install the axle shaft in the differential.

Conventional differential

11. Install the lock washer in the groove and secure the washer by pressing on the shaft flange.

12. Insert the gear shaft into place, align the hole in the shaft with the bolt hole, wrap and tighten the lock bolt to the specified torque.

Locking differential

13. Install lock washers (pinion must be extended).

14. Gently feed the half shaft» so that the puck moves away from the stop.

15. Slide the gear shaft into place so that the groove is opposite the bolt hole. Wrap and tighten a bolt with the set moment.

16. Next, the assembly is performed in the reverse order.