2. The system includes a separate air pump and check valve (see photo), which is controlled by the processor unit.

6. The pump is checked by the pressure of the jet at its outlet with a warm engine at 1500 rpm. If the pressure is weak to the touch, replace the pump.

7. The rest of the system checks are carried out in a car service, as reading diagnostic codes is required.

Air pump pulley and filter

8. Compress the drive belt and loosen the pulley bolts.

9. Remove the drive belt.

10. Turn away bolts and remove a pulley.

11. Remove the filter with needle nose pliers (do not pry the filter with a screwdriver!) (see photo).

12. Install the new filter by hand. It is not allowed to drive it even with light blows.

Valve

13. Disconnect the hose from the valve.

14. Turn out the valve from a socket.

15. The new valve must exactly match the one being replaced.

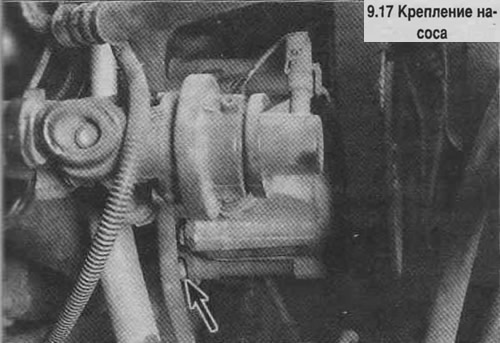

Air pump

16. Remove the pulley and drive belt from the pump.

17. Turn away bolts of fastening and remove the pump (see photo).

18. Disconnect the hose from the pump.

19. Installation is carried out in the reverse order.

Attention! Tighten the pump mounting bolts after installing all parts.