Camshaft lobe lift check

1. The degree of wear of the camshaft cams is checked by the amount of cam lift before removing the camshaft. Remove the head covers, cylinders.

2. Set the piston of the 1st cylinder to the TDC of the compression stroke.

3. The check begins with the cams of the 1st cylinder. Loosen the rocker nuts and turn to the side. Install the dial indicator so that the indicator leg runs parallel to the axis of the rod and rests against the end of the rod (see photo).

4. Set the indicator to zero, turn the crankshaft in the direction of normal rotation. Immediately, after the indicator arrow deviates in the opposite direction (the reading will start to decrease), read the reading which is equal to the cam lift.

5. Set the piston of the 1st cylinder to TDC of the compression stroke again.

6. Move the dial indicator to another push rod of the 1st cylinder and repeat the test.

7. Repeat the test for the valves of the remaining cylinders Since each piston must be at TDC on the compression stroke, set the cylinders one by one, in the order of engine operation.

8. Compare results with normative. If the decrease in the size of the cam due to wear exceeds the norm, then replace the camshaft.

9. Remove the intake manifold, rocker arms, push rods, camshaft sprocket and timing chain. Remove the radiator.

Attention! If the vehicle is equipped with air conditioning, it may be necessary to remove the air conditioning condenser. If the condenser is removed, the system must first be depressurized in a car service.

10. Pushers can be removed using a special tool. On late production engines, the tappets can be reached with a small magnet or fingers. You can also remove the pusher with a curved scriber by prying off the retaining ring at the top of the pusher. The use of pliers is not allowed.

11. Remove the pushers and store them in the order of the initial installation, so that they can be installed in their original places during assembly (see photo).

Attention! On engines with roller tappets, the tappet restrictor plates are removed first. It is forbidden to remove the camshaft until the pushers are removed.

12. On 1994 4.3L V6 engines, remove the balance shaft gears (see below).

13. On part of the V6 engines, remove the camshaft thrust plate (see photo). Screw 150mm bolts into the camshaft sprocket bolt holes to use as handles when removing the camshaft from the cylinder block (see photo).

14. Carefully remove the camshaft, avoiding damage to the journals on the edges of the cylinder block.

Camshaft and bearings - check

15. Clean the camshaft and check the condition of the journals. If there are signs of wear on the journals, then the camshaft bearings are also worn. In this case, the camshaft and bearings must be replaced (bearings are changed in a car service, for this you need to remove the engine and disassemble it).

16. If the necks are in a satisfactory condition, then check their diameter in several places, determine the taper and ovality of the camshaft bearing journals (see photo).

17. Check the condition of the camshaft cams, for signs of overheating, the risk of chipping and other damage. If the cams are in good condition and if all dimensions are correct, then the camshaft can continue to be used.

Pushers

18. Clean the pushers one by one and dry, keeping the order of their installation.

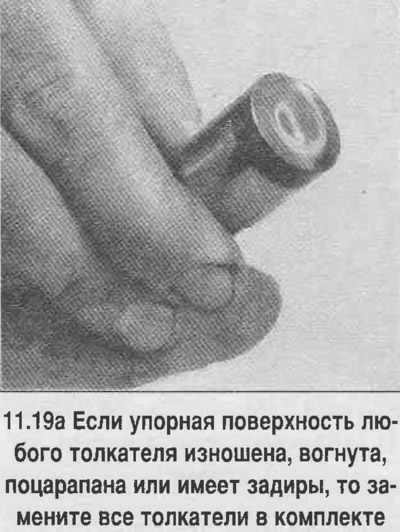

19. Check up wear of a persistent surface of a pusher, a saddle of a bar and a condition of a lateral surface. The thrust surface of the pusher has a concavity with a large radius of curvature. If the thrust surface is heavily worn (see photo), the camshaft and tappets must be replaced. If the side surface is worn (which is unlikely), then check the condition of the holes in the cylinder block. Check the condition of the saddles of the rods and the ends of the rods themselves.

20. The camshaft and pushers change only together. Put the removed pushers in their original places.

Roller pushers

21. Check the condition of the rollers, make sure the rollers rotate freely without excessive play (see photo). The procedure for checking roller pushers is no different from that discussed above for conventional pushers.

22. Removed roller tappets can be installed with a new camshaft, and a removed camshaft can be used with new roller tappets.

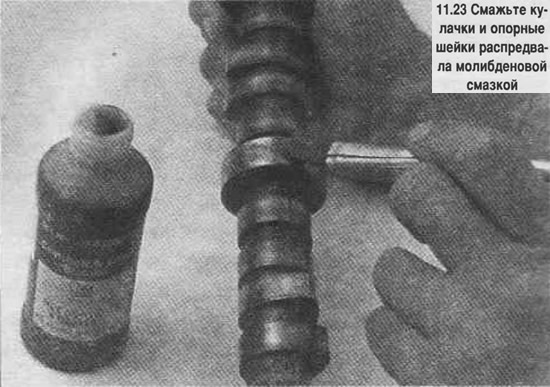

23. Lubricate the cams and camshaft bearing journals with molybdenum grease (see photo).

24. Install the camshaft in place.

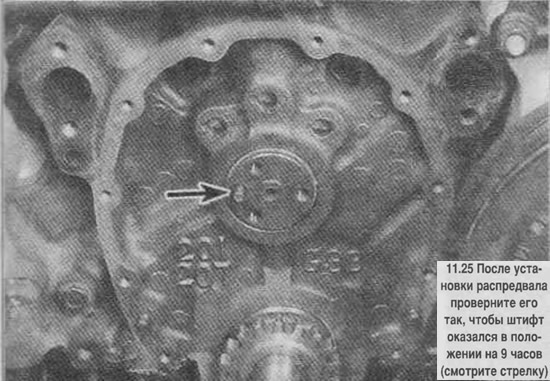

25. Turn the camshaft so that the pin is in the 9 o'clock position (see photo).

26. On 4.3 liter engines from 1994 onwards. install balance shaft gears (see below).

27. Install the timing chain and sprockets.

28. Lubricate the tappets with clean engine oil and install in. cylinder block. Install the removed pushers to their original places.

29. Next, the assembly is performed in the reverse order.