2. Raise the front of the car.

3. Drain the oil and remove the oil filter.

4. Disconnect the exhaust pipe from the manifold.

5. On a part of cars, disconnect the suspension struts on the cover of the bell-shaped crankcase, remove the strut brackets from the front engine mounts. Disconnect the oil cooler and transmission fluid cooler hoses from the oil pan.

6. Remove the bottom cover of the transmission bell housing.

7. Remove the starter.

All-wheel drive models

8. Remove the bulkhead.

9. Remove the front propeller shaft.

10. Turn away two right bolts and two nuts of a forward semiaxle. Remove one top left bolt and nut.

11 Remove the front axle shaft by rotating the axle shaft forward as the wheel turns in the opposite direction.

Vehicles with 7.4 liter engine

12. Disconnect the oil pressure gauge tube on the side of the cylinder block.

13. Remove the cover of the ignition distributor to prevent it from breaking when hanging the engine.

14. Turn away bolts and shift a casing of the fan back, having removed it from the fan. If necessary, insert a piece of cardboard between the fan and the heatsink to protect the space between the fins of the heatsink from being hit by the fan blades when the engine is suspended.

15. Turn away through bolts of support of the engine.

16. Carefully hang out the engine with a hoist, raising it by 75 mm. Be careful not to damage the radiator and distributor cap.

Attention! Lifting the engine with a jack is not allowed in order to avoid damage to the coarse oil filter.

17. Place a block of wood between the cross member and the cylinder block, next to the supports, to hold the engine up, then remove the hoist.

All engines

18. Turn the crankshaft so that the alignment mark on the front flywheel is facing down.

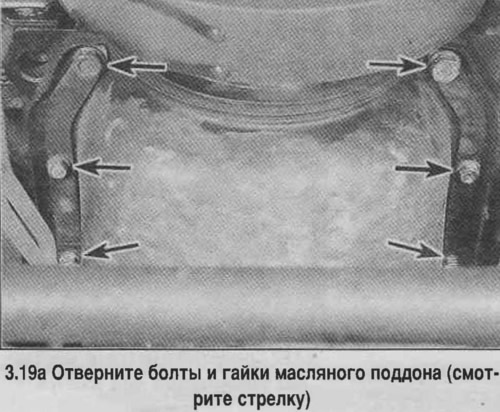

19. Turn away bolts and nuts of the pallet (see photo).

20. Remove the pan by tilting the back down.

21. Clean the sump.

22. Wash sealing surfaces with acetone. Clean the bolt holes in the cylinder block.

23. Check up presence on a demountable plane of the pallet of deformations, especially about apertures under bolts. If necessary, straighten the plane with a hammer.

24. Install new pan seals in place of the old ones (except for engines that have a one-piece rubber gasket), by lubricating them with RTV sealant. Apply a bead of RTV sealant to the joints in the cylinder block. Secure the side gaskets to the oil pan by lubricating them with the same sealant.

25. Check the condition of the solid rubber gasket used on some models. Replace gasket if damage is found.

Attention! Engine pan gasket on 7.4 liter engines made in 1997 multiple use. This gasket is only changed if damage is found. Before installing, apply a bead of RTV silicone sealant to the corners of the gasket.

26. Install under the bottom in place and tighten the bolts. Displacement of the pallet after installation is not allowed. Tighten the bolts/nuts in 3 stages to the specified torque, starting from the center, in a spiral sequence,

27. Next, the assembly is performed in the reverse order.