2. Starting at the front of the cylinder head, loosen and remove the rocker stud nuts. Label and store them separately to reinstall them in their original locations.

Attention! If only the pusher rods are removed, then loosen the nuts enough to move the rocker arms to the side, after which you can get the rods.

3. Remove the rocker arms and ball studs and place them, along with nuts, in the marked bags to re-install in their original locations during reassembly.

4. Remove the push rods, label and store them separately so that they can be reinstalled during assembly (see photo).

Attention! On the 7.4 liter engine, the exhaust valve lifters are longer than the intake valve lifters.

5. Check each rocker for wear, chips and other damage, especially at the points of contact with the pushers and valve stems.

6. Check up cleanliness of an opening in a persistent part of a yoke which adjoins a pusher.

7. Check up dredging of yokes under spherical axes. If in these places the rocker arms are worn out or damaged, then replace them with new ones along with the ball axles.

8. Inspect the push rods for cracks and excessive end wear. Roll each pusher over a mirror to see how it deforms.

9. Lubricate the bottom end of each rod with clean engine oil or molybdenum grease and install them in their original positions. Make sure the rods are in the pusher seats.

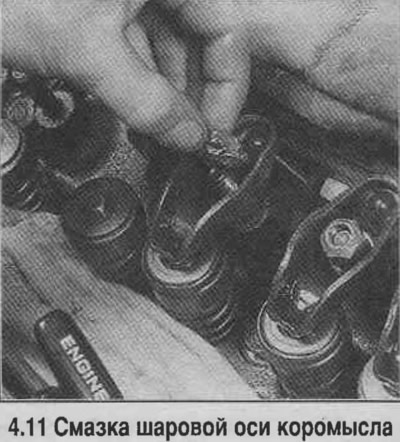

10. Lubricate the ends of the valve stems and the top ends of the push rods with molybdenum grease (see photo).

11. Install the rocker arms in place, then install the ball shafts and tighten the nuts. Lubricate the ball shafts with molybdenum grease. Make sure the nuts are flat on the ball shaft (see photo).

Adjustment of valves (all models except models with 7.4 liter V8 engine produced since 1991 and models with V6 engine produced since 1995)

Attention! On models with a 7.4 liter V8 engine manufactured since 1991, as well as models with a U6 engine manufactured since 1995, valve adjustment is not provided. On the studs / bolts of the rocker arm, a restrictive shoulder of the rocker arm is provided. After renovation (or replacement) valves, tighten the nuts/bolts to the specified torque. If the parts of the gas distribution mechanism were not ground or machined, which could lead to a change in the clearance in the valves, then after tightening the nuts / bolts, the clearance in the valves will be set exactly.

12. Set the piston of the 1st cylinder to the TDC of the compression stroke (see below).

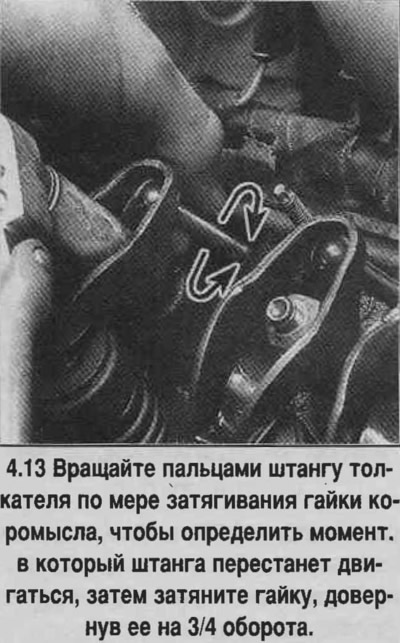

13 Tighten the rocker nuts of the 1st cylinder so that the push rod turns with your fingers under a noticeable effort (see photo).

14. Tighten the nuts 3/4 turn to center the pushrods. The valves of the 1st cylinder will now be adjusted.

On V6 engine

15. If the car is equipped with a V6 engine, then it is possible to adjust the intake valves of the 2nd and 3rd cylinders, as well as the exhaust valves of the 5th and 6th cylinders without changing the position of the crankshaft. Then turn the crankshaft one full revolution and adjust the inlet valves of the 4th, 5th and 6th cylinders and the exhaust valves of the 2nd, 3rd and 4th cylinders.

On a V8 engine

16. If the car is equipped with a V8 engine, then at the same time you can adjust the intake valves of the 2nd, 5th and 7th cylinders, as well as the exhaust valves of the 3rd, 4th and 8th cylinders. Then rotate the crankshaft one full revolution and adjust the inlet valves of the 3rd, 4th, 6th and 8th cylinders and the exhaust valves of the 2nd, 5th, 6th and 7th cylinders.

All engines

17. Establish covers of heads of cylinders. Start the engine, listen to its work. Make sure there are no leaks.