Attention! When the engine is completely disassembled, the piston rings must be replaced, regardless of their condition.

2. Remove carbon deposits from the piston ring grooves (see photo).

3. Wash the pistons and connecting rods with solvent, carefully clean the oil drain holes in the piston grooves and the hole in the connecting rod.

4. If there are no signs of significant wear and if cylinder boring is not required, then the pistons should not be changed. Normal wear shows up in the form of traces of uniform vertical wear on the rubbing surface of the piston and in the form of a slight weakening of the fit of the upper compression ring. However, piston ring replacement is mandatory.

5. Carefully check up presence of cracks on a skirt of the piston, on bosses of a piston pin and on landing sites of piston rings.

6. If chips and scuffs are observed on the piston, then this indicates frequent overheating of the engine. In this case, a thorough check of the lubrication and cooling systems is required. The burning of the piston bottom indicates the operation of the engine with an incorrect setting of the ignition timing.

7. The cause of burning of the piston crown at the edges is usually abnormal combustion (detonation). If these defects are found, then their cause must be determined and eliminated, (as a rule, the reason is the suction of air in the manifold through a leaky gasket, a malfunction of the devices for preparing a combustible mixture or the recirculation system).

8. Piston corrosion in the form of small pits (pitting) indicates penetration into the combustion chamber (as well as in the crankcase) coolant.

9. Measure the gap between the groove and the new ring (see photo). If the clearance exceeds the specified limit, the piston should be replaced.

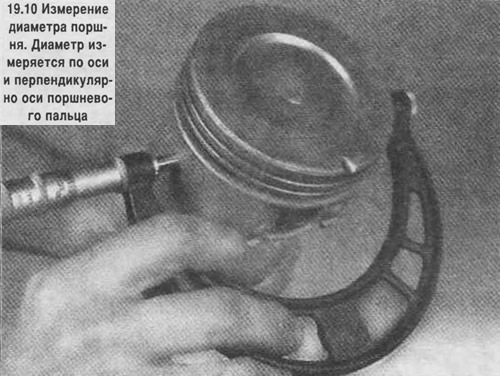

10. Check the clearance between the piston and the cylinder by measuring the diameter of the cylinder (see above) and the piston diameter of the given cylinder (see photo). If the gap, which is calculated as the difference between these diameters, exceeds the established limit, then the cylinder block must be bored, and the pistons and rings should be replaced with repair ones.

11. Check up a backlash between a piston finger and a rod head for what shake the piston and a rod in opposite directions. If the backlash is noticeable, then repair of this connection in a car service is necessary.

12. Checking the connecting rod heads and their deformation, as well as replacing pistons and connecting rods, are carried out only in a car service.

Attention! If the pistons or connecting rods will not be changed, then this connection is not allowed to be disassembled.

13. Check up existence on rods of cracks and other damages. Remove the connecting rod bearing caps, remove the bearings, wipe the seating surfaces on the cap and on the connecting rod, check for cracks, scratches and burrs. After checking, assemble the connecting rod, installing the bearings in place, tighten the nuts by hand.