Attention! Before removing the pistons and connecting rods, remove the cylinder head, oil pan and oil pump, referring to the relevant sections in Chapter 2, Part A.

1. Check with your fingernail for a shoulder formed as a result of cylinder wear from the piston ring. The bead is removed by reamer (see photo). If you do not perform this operation, then when removing the piston with the connecting rod from the cylinder, the piston may break.

2. Turn the engine over so that the crankshaft is at the top.

3. Before removing the connecting rods, check their end play using a feeler gauge set. Insert a feeler gauge between the connecting rod and the crankshaft web. By selecting the thickness of the probes, achieve the disappearance of the backlash (see photo). The axial play will be equal to the total thickness of the probes at which the play disappears. If the end play of the connecting rod exceeds the standard value, then the connecting rod should be replaced. In exactly the same way, measure the end play on the other connecting rods. If new connecting rods are installed (or crankshaft), then the axial play may be below normal (in this case it is necessary to grind the connecting rods).

4. Check up presence of labels on rods and covers of rods. If there are no marks, then mark them so that the number of marks corresponds to the number of the cylinder in which this connecting rod is installed (see photo).

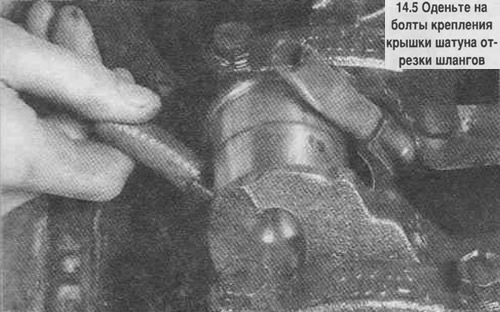

5. Loosen the nuts by turning them 1/2 turn at a time until the nuts can be turned away by hand. Remove the cover from the connecting rod of the first cylinder together with the connecting rod bearing. Do not remove the connecting rod bearing from the cover. Put hose pieces on the connecting rod cap bolts so as not to damage the crankshaft journal and cylinder walls when removing the connecting rod (see photo). Push the piston assembly with connecting rod and upper connecting rod bearing through the top of the cylinder, resting the hammer handle on the upper connecting rod bearing. If resistance is felt to the piston exit, then once again check the completeness of the removal of the shoulder in the upper part of the cylinder.

6. Repeat the procedure for all other cylinders. Assemble the connecting rod caps to the connecting rods, hand-tighten the cap bolt nuts. Until assembly, store the earbuds in their original location.