2. To obtain accurate test results, the engine must be warmed up to normal temperature and the battery fully charged.

3. Turn out spark plugs. Fully open the throttle, turn off the ignition by disconnecting the low voltage wires from the coil.

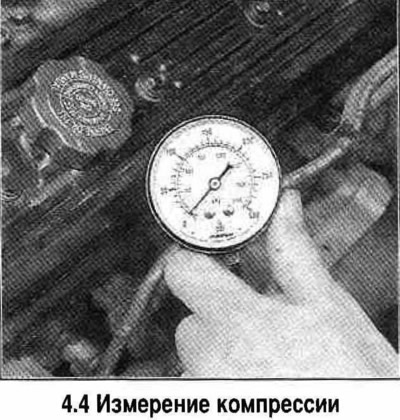

4. Insert a compression gauge into the spark plug hole of the 1st cylinder (see photo). Turn on the starter and watch the pressure gauge. On a healthy engine, the pressure should build up quickly. Low pressure after the first piston stroke and a slow build-up on subsequent compression strokes indicates worn piston rings. If the pressure is low after the first piston stroke and does not increase on subsequent compression strokes, the cause is a leak in the valves or a leaky gasket or cylinder head. Write down the highest compression value.

5. Repeat the procedure for the remaining cylinders.

6. If, after the introduction of oil into the cylinder, the compression increased, then we can conclude that the piston rings are worn out. If the compression increases slightly, then the leak is through the valves, or the head gasket.

7. If the compression is equally low only in two adjacent cylinders, then the most likely cause is a burnt gasket between these cylinders.

8. If the compression value exceeds the norm, then the combustion chamber is covered with soot. In this case, the cylinder head must be removed and carbon deposits removed.

9. With a strong difference in compression in the cylinders, the car should be taken to a service station to check the tightness of the head and cylinder block by pressing.

Warning. Before starting the engine, carefully check the condition of the fan blades (the presence of damage or cracks on them). When the motor is running, do not put your hands too close to the fan, keep the appliance at a sufficient distance from the fan and do not stand in line with the rotating impeller.

Check the vacuum gauge reading. On a serviceable engine, the vacuum gauge should show a vacuum of 430-560 mm Hg, and the gauge needle should be practically motionless.

The following is a description of the nature of the readings of the vacuum gauge and the methodology for determining the state of the engine based on them.

A. Too low a vacuum usually indicates a leak in the gasket between the intake manifold and the throttle chamber, the vacuum hose, as well as too late ignition or the wrong opening and closing of the valves. Before removing the toothed belt covers and checking the alignment of the timing marks, check the ignition setting with a stroboscope and eliminate all other possible causes, guided by the test methods described in this Chapter.

b. If the vacuum gauge readings are 75 -200 mm Hg. below normal and are unstable (arrow twitches), then this indicates a leak in the gasket at the inlet of the suction manifold or a malfunction of the injector.

V. If the arrow regularly deviates by 50-100 mmHg, then the cause is valve leaks. To confirm this conclusion, check the compression in the engine cylinders.

d. Needle fluctuates irregularly towards low readings, or trembles to show low vacuum. The likely cause is increased resistance to valve movement, or interruptions in the operation of the cylinders. Check cylinder compression and inspect spark plugs.

e. If at idle the needle fluctuates rapidly within 100 mm Hg, and engine operation is accompanied by smoke from the muffler, then the valve guides are worn out. To verify this conclusion, it is necessary to test the combustion chambers for leaks (with air pumping). If the arrow fluctuates rapidly and at the same time an increase in engine speed is observed, then it is necessary to check the tightness of the intake manifold gasket, the elasticity of the valve springs. Such indications can also be due to burnt valves and interruptions in the operation of the cylinders (ignition failures).

e. Weak fluctuations of the arrow (within 20-30 mm Hg in both directions) indicate unstable ignition operation. Check all foreseen settings and adjustments, if necessary, connect an ignition system analyzer to the engine.

h. In case of large fluctuations of the arrow, check the compression in the cylinders, or carry out leak tests, as the causes of the malfunction may be an inoperative cylinder, or a leak in the cylinder head gasket.

and. If the instrument readings change slowly over a wide range, then check the cleanliness of the pipelines of the forced crankcase ventilation system, the correct adjustment of the combustible mixture, the tightness of the gaskets of the throttle body, or the intake manifold.

And. Open the throttle sharply, and when the engine speed reaches 2500 rpm, release the throttle. The shutter should slowly return to its original position. The vacuum gauge readings should drop to almost zero, then rise and exceed the control readings corresponding to stationary idling by about 125 mm Hg, after which the vacuum should be restored to its previous level. If the vacuum is restored slowly, and there is no excess of the control reading when the damper is suddenly opened, then the cause may be worn piston rings. If the vacuum recovery is extremely slow, check the cleanliness of the exhaust tract (usually muffler or catalytic converter). The easiest way to do this is to open the exhaust tract in front of the suspicious area and repeat the test.

Checking compression in the engine cylinders

A. The results of the compression test in the engine cylinders make it possible to judge the condition of a group of parts in the upper part of the engine (pistons, rings, valves and cylinder head gaskets). Namely, a decrease in compression may be due to leaks in the combustion chambers due to wear of the piston rings, damage to the valve heads and seats, burnout of the cylinder head gasket.

Comment. To obtain accurate test results, the engine must be warmed up to normal temperature and the battery fully charged.

b. Start by cleaning the areas near the spark plugs by blowing out with compressed air (in the absence of a compressor, blow the areas with an automobile, or even bicycle, pump). This is necessary in order to prevent dirt from entering the cylinders when measuring compression.

V. Remove spark plugs.

d. Fully open the throttle and secure it in that position.

e. Disconnect the central high-voltage wire from the ignition distributor cover, connect it to ground on the cylinder block. For reliability, connect to ground using a special shorting piece of wire with alligator clips at both ends. It also does not hurt to remove the fuse for the electronic fuel injection system on the mounting block, which will ensure that the electric fuel pump is completely turned off when measuring compression.

e. Insert a compression gauge into the spark plug hole.

e. Engage the starter and rotate the crankshaft a few revolutions while observing the pressure gauge on the compression gauge. On a healthy engine, the pressure should build up quickly. Low pressure after the first piston stroke and a slow build-up on subsequent compression strokes indicates worn piston rings. If the pressure is low after the first piston stroke and does not increase on subsequent compression strokes, then the cause is a leak in the valves or a leak in the cylinder head gasket (the cause may also be the formation of cracks in the head). Compression loss can also be caused by carbon deposits on the valve heads. Write down the highest compression value.

h. Repeat the measurement procedure For the remaining cylinders, compare the results with the normative data.

and. Inject some engine oil into each cylinder through the spark plug hole (about three full syringe nipples), then repeat the test.

And. If, after the introduction of oil, the compression increased, then we can make an unambiguous conclusion that the piston rings are worn out. If the compression increases slightly, then the leakage occurs through the valves, or the cylinder head gasket. Leakage through valves can be caused by burnt valve seats and/or bevels, as well as deformation or cracking of valve stems.

j. If the compression is equally low only in two adjacent cylinders, then the most likely cause is a burnt gasket between these cylinders. This conclusion will be confirmed by the appearance of traces of coolant in the combustion chambers or in the crankcase of the crankshaft of the cylinder block.

l. If the compression value in one of the cylinders is 20 percent lower than in the other cylinders and the engine idles erratically, then the cause may be a worn camshaft cam that controls the exhaust valve.

m. If the compression value exceeds the norm, then the combustion chamber is covered with carbon deposits. In this case, the cylinder head must be removed and carbon deposits removed.

n. If the compression in all cylinders is low, or very different for different cylinders, then it is necessary to test the combustion chambers for tightness, for which you need to contact a specialized workshop. As a result of the tests, leak locations must be accurately determined and a quantitative characteristic of the leak given.