2. Lay out the pistons with connecting rods and new piston rings in such order that the set of rings matches the cylinder on which the clearance will be measured.

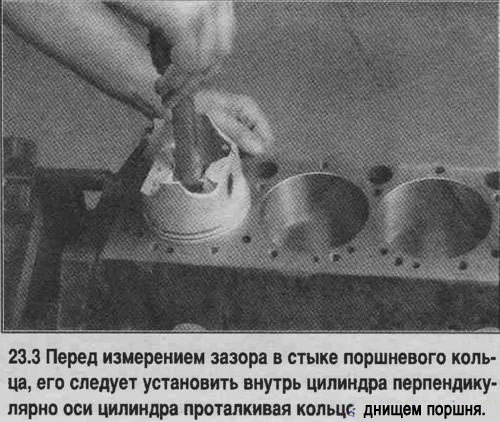

3. Insert the upper ring into the first cylinder and push the piston head inward, so that the ring inside the cylinder becomes perpendicular to its axis (see photo). The ring should be in the right part of the cylinder, in a position corresponding to the BDC of the piston stroke.

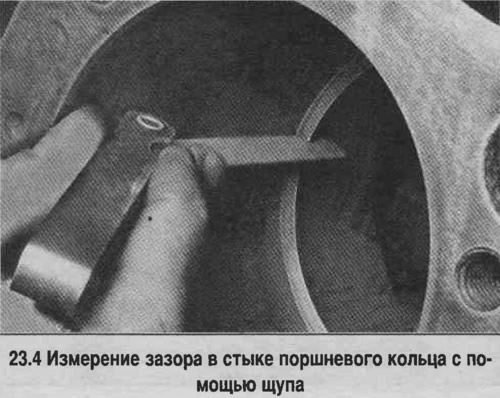

4. The gap at the junction of the piston ring is measured with feelers and is equal to the total thickness of the feelers inserted into the gap (see photo). The feeler gauges should pass through the gap with little effort. Compare the result with the standard value. If the gap differs from the norm, then check the correct selection of rings.

5. If the gap at the joint of the piston ring is too small, then increase it by filing the ends with a file (see photo).

6. The gap should not exceed 0.1 mm, regardless of the type of engine. However, you should make sure that the rings are matched correctly.

7. Repeat measurements for each ring installed in the first cylinder, as well as for each of the rings installed in the remaining cylinders. Store pistons and rings so that they are installed in the cylinder in which the joint clearance was checked.

8. Install the rings on the pistons.

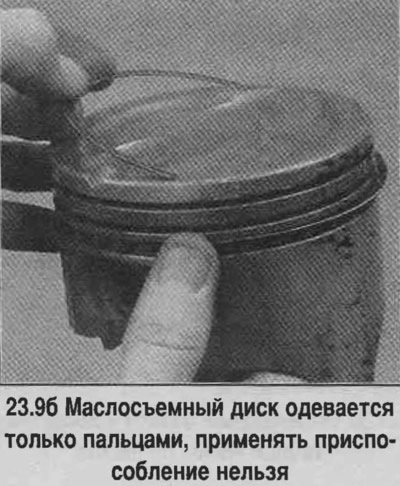

9. The oil scraper ring is installed first (the bottom of the piston). This ring is made up of three parts. Install spacer/expander in groove (see photo). If the piston has a locking pin to prevent the ring from turning on the piston, make sure there is a pin that is pressed into a hole inside the piston groove. Then install the lower oil scraper disc. When installing oil scraper discs, it is impossible to use a device for dressing rings, as they may break. Insert one end of the oil scraper disc into the groove of the piston, between the separator and the horizontal platform of the groove, and firmly holding the end of the disc inserted into the groove, insert the second end of the disc into the groove with your finger (see photo). Proceeding in the same way, install the second oil ring disc.

10. After installing all parts of the oil scraper ring, make sure that the upper and lower discs turn freely in the groove.

11. Install the middle ring (number 2). This ring is stamped with a mark that must face towards the piston crown. Insert the ring into the fixture and move the ring into the middle groove of the piston (see photo).

Attention! During installation, the rings are oriented in accordance with the instructions on the package. Do not confuse the top and bottom compression rings as they have different cross-sectional profiles.

13. Install the top compression ring in the same way.

14. In the same order, install the rings on the remaining pistons.