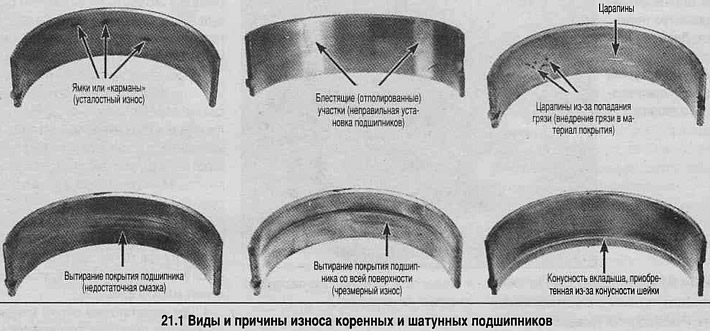

2. Causes of destruction of crankshaft bearings are insufficient lubrication due to improper assembly, contamination and penetration of foreign particles, frequent engine overloads, corrosion, etc. Regardless of the cause that caused the destruction of bearings, it should be eliminated.

3. To prevent accelerated wear due to contamination, keep the engine assembly clean. During operation, it is recommended to change the oil and filters more often.

4. In case of insufficient lubrication, the bearing coating material is wiped off the steel base, the bearing is chipped from overheating (there is a bluish tint).

5. When driving in heavy engine conditions (at wide open throttle, or at low speed in high gear) there is a detachment of the bearing coating from the steel base in the form of small particles, the bearings are subjected to fatigue wear.

6. Frequent trips over short distances can cause corrosive wear of bearings, because due to insufficient warming up, condensed moisture does not have time to be removed.

7. Incorrect installation of bearings during assembly also leads to premature wear. If the clearance in the bearings is less than normal, then their lubrication is difficult, which leads to wear as well as due to «oil starvation».

8. When assembling, do not touch the earmold surfaces with your fingers.

9. Inserts of main and connecting rod bearings during major repairs are subject to mandatory replacement.