Comment. Before dismantling the crankshaft, remove the flywheel (or torque converter drive plate), all parts on the crankshaft toe, chain, sump, oil pump and pistons assembled with connecting rods.

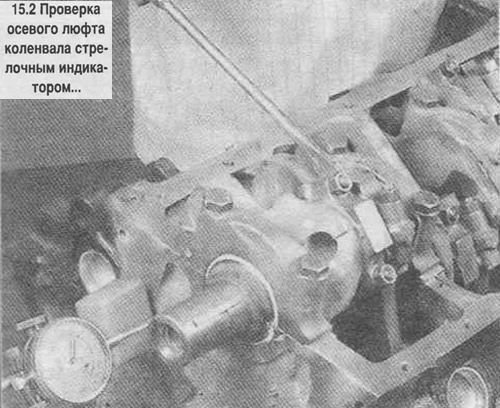

1. Before dismantling the crankshaft, check the end play. Install the indicator so that its leg is parallel to the axis of the crankshaft and touches one of its cheeks (see photo).

2. Move the crankshaft towards the rear of the engine, applying maximum effort, and in this position, set the indicator scale to zero. Then push the crankshaft towards the front of the engine and read the indicator. The amount of axial play is equal to the distance that the shaft has moved. If the axial play exceeds the standard value, then check the wear of the thrust surfaces of the crankshaft. If the wear is insignificant, then the play must be compensated by installing new thrust half rings.

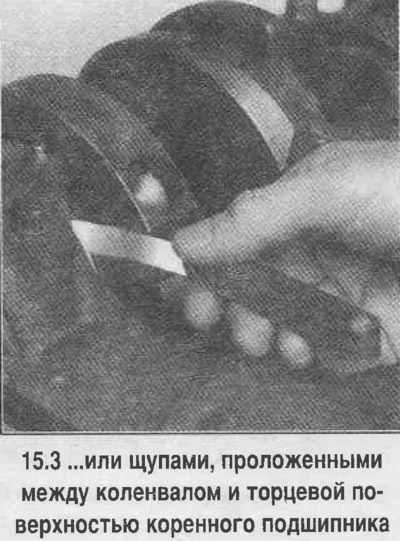

3. If there is no indicator head, you can measure the backlash using a set of feeler gauges. Move the crankshaft towards the front of the engine. Insert a feeler gauge between the crankshaft web and the end face of the main bearing (see photo) and measure the end play, which is equal to the maximum thickness of the probes to be inserted.

4. Check up marking on covers of radical bearings which has to correspond to cylinder number. Usually the covers are numbered starting from the front of the engine. If there is no marking, then mark with a core. Arrows are usually cast on main bearing caps (see photo), that are directed towards the front of the engine. Loosen each of the main bearing cap bolts 1/4 turn at a time, in reverse order, until the bolts can be loosened by hand.

5. With light blows of a hammer through a soft spacer, slide the main bearing caps out of place and remove them from the engine. Do not allow the main bearing to fall out if it remains in the cap.

6. Carefully, working with an assistant, remove the crankshaft. Install the covers together with the bearings in place, tighten the bolts by hand.