2. If the head of the block was handed over to a workshop for repair of valves, then the valves will already be installed in place assembled with all the details.

3. Lubricate the valve stem with engine oil or molybdenum grease and install the first valve, starting at either end of the cylinder head.

4. Three different types of caps are used on the engines in question, depending on the year of manufacture, displacement and power. As a rule, ring caps are installed, which are put on the guide sleeve. Flat seals are also used, which are inserted into the groove on the valve stem directly under the cracker groove. Umbrella caps are provided on some of the engines. Umbrella caps are most often installed together with flat seals. Install the valve stem seal on the valve guide (see photo).

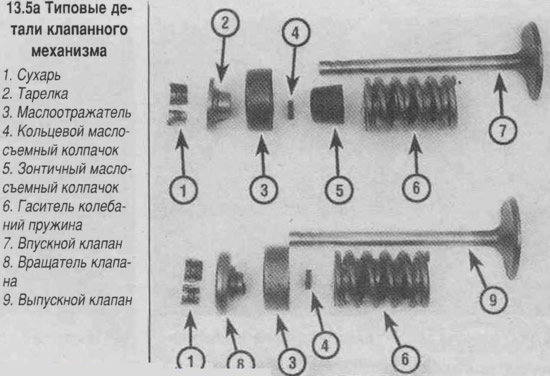

5. Put on the spring washer (or pack of washers), install the spring (or both springs) valve, oil deflector, plate (or valve rotator) (see photo).

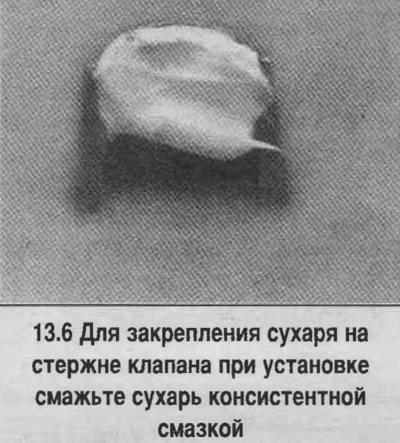

6. Compress the valve spring with a tool and install the cotters into the groove on the valve stem. If an o-ring is provided to seal the valve stem, carefully install it into the lower groove on the valve stem without twisting. Carefully release the spring, making sure that the crackers have entered the upper groove of the valve stem. If necessary, before releasing the valve spring, lubricate the cotters with grease in order to temporarily secure them to the valve stem (see photo).

7. Repeat all steps for the remaining valves. Make sure that the entire set of valve parts is installed in its original place. After assembly, check the tightness of the sealing rings. To do this, put the vacuum pump adapter on the valve disc or rotary device, and create a vacuum (see photo). If the vacuum cannot be created, then the seal is leaky and must be replaced before installing the head on the engine.

8. Check the loaded height of the spring with a ruler, caliper with depth gauge, or indicator head (see photo). The length of the spring is measured from the spring seat, or shim, to the top of the oil slinger (or the base of a dish or rotator). If the height is higher than indicated in the Technical data, then add the shims to the bag under the springs.

Attention! It is strictly forbidden to reduce the length of the spring under load against the standard.

9. Lubricate the rocker arms and ball joints with molybdenum grease and install the rocker arm in place. Tighten the rocker nuts 3-4 turns.