Attention! Regardless of the service interval, check for leaks under the vehicle and fix them immediately.

Checking the engine oil level

1. Install the car on a flat horizontal platform.

2. The oil level in the engine is checked using a dipstick, the dipstick of which is located at the bottom of the engine (see photo).

3. The oil level is checked before driving or at least 15 minutes after stopping a hot engine.

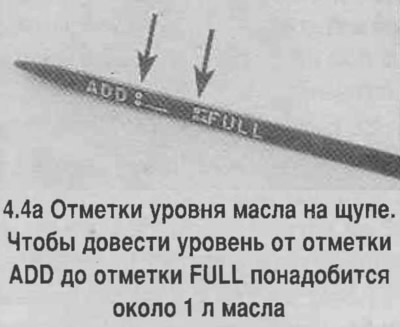

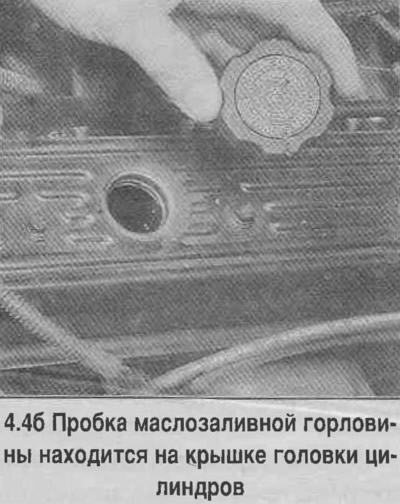

4. Remove the oil gauge dipstick and wipe it with a clean rag. Insert the dipstick back into the tube until it stops, remove the dipstick again. Check the oil level at the edge of the oil film on the dipstick. The oil level should be between the ADD and FULL marks. If it is necessary to add oil, unscrew the filler cap on the cylinder head cover (see photo) and add fresh oil of the desired brand, bringing the level to the upper mark.

5. When finished, insert the dipstick into the oil indicator tube and tighten the plug.

6. Always maintain the oil level between the two indicated marks. If the oil level is too low, the engine may not be lubricated properly and may be damaged. With excessive refueling with oil, the spark plugs are oiled, oil leaks from under the gaskets and seals develop.

7. The oil must be changed if, when you run your fingers over the dipstick, (before rubbing) solid particles are felt. Increased oil consumption indicates engine failure (wear of piston rings, cylinders, pistons, valve guides and valve stems, damage to the cylinder head gasket). If a milky tint is detected in the oil on the dipstick (fluid from the cooling system gets into the oil), the engine also needs to be repaired.

Coolant

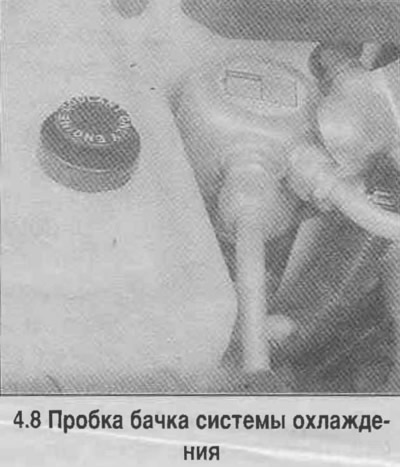

8. All vehicles covered in this manual are equipped with a pressurized cooling system. The expansion tank is next to the radiator (see photo).

9. The liquid level in the expansion tank depends on the engine temperature. On a cold engine, the fluid level must be brought to a level slightly above the FULL COLD tank mark, on a warm engine - up to the FULL HOT mark. To do this, unscrew the plug of the expansion tank and add a 50/50 antifreeze mixture with water. Do not add inhibitors or other additives to the liquid.

10. The need for frequent topping up of fluid indicates the presence of a leak in the system and the need to eliminate its cause. Visually check the condition of the radiator and all hoses. If visually no leaks are found, then the entire cooling system should be pressure tested and the radiator cap checked. Pressure testing will help detect even a minor, previously imperceptible leak. At the end, wrap the plug of the expansion tank.

11. Replace fluid if severe rust contamination is found.

12. If necessary, unscrew the radiator cap, wrap it with rags and turn it to the first stop, then after waiting a little, remove the cap.

13. Do not allow antifreeze to get on the painted surface of the body.

Restoring the fluid level in the windshield washer reservoir

14. The tank is located in the engine compartment (see photo).

Restoration of the electrolyte level

15. Cars are equipped with a maintenance-free battery (there are no plugs on the battery case). If a serviceable battery is installed, the plugs should be removed periodically and the electrolyte level checked. Top up with distilled water if the level drops.

Checking and restoring the fluid level in the hydraulic clutch and brakes

16. Clutch reservoirs (hydraulic drive is used on cars with manual transmission) and brakes are located next to the vacuum booster.

17. Liquid level must be above MIN on the wall of the nutrient tank (see photo).

18. If necessary, restore the liquid level, first wipe the tank, then remove the plug.

19. Only the recommended grade should be filled in. Mixing liquids is not allowed, as the destruction of parts and subsequent failure of the hydraulic drive system is possible. It is also forbidden to add liquid that has stood for a long time in an open vessel.

20. Before topping up the liquid, check the remaining liquid in the nutrient tank and the walls of the tank for foreign matter and dirt particles. If contamination is found, the system should be flushed and the fluid replaced.

21. Keep in mind that the fluid level in the reservoirs can gradually decrease over a long time due to the natural wear of the brake pads. A rapid drop in the fluid level in the feed tank indicates a leak in the hydraulic drive system and must be repaired immediately.

22. If at least one of the sections of the tank is empty, then it is necessary to remove air from the hydraulic actuator.