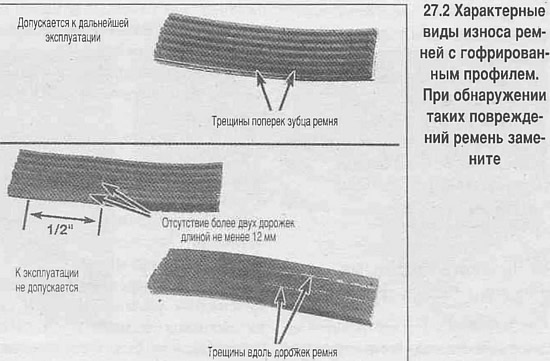

2. With the engine off, check by touch (or visually by illuminating with a flashlight) belt condition (see photo), the presence of cracks, delaminations, burning or hardening on it.

3. Check the condition of the ribs on the inside of the belt. All edges must be of equal depth, with none of the unequal surface.

4. The belt tension is automatic, set by the tensioner, so tension adjustment is not required.

5. To replace the belt, turn the tensioner counterclockwise with a wrench (see photo) and remove the belt. Then slowly release the tensioner.

6. When purchasing a new belt, compare it with the removed belt. The new belt must fully match the removed one in width and length.

7. When installing a new belt, make sure it is routed correctly throughout the track. The ribs of the belt should fit into the grooves on the pulleys. The route of the belt is indicated on the plate in the engine compartment (see photo).