Upper arm ball joint

1. Loosen the wheel nuts, raise the front of the vehicle and place it on stands. Put the car on the parking brake. Remove the wheel.

2. Install a floor jack under the lower suspension arm and hang the arm slightly. Use a large screwdriver to pry up the upper arm and try to wiggle it. Any noticeable movement indicates wear on the ball joint. Squeezing the steering knuckle, try to move it by the top. If you feel any play, replace the ball joint of the lever.

Lower arm ball joint

3. Raise the vehicle and place it on stands.

4. Hang the suspension with a jack (the jack must bear the weight of the suspension). Measure the distance between the edge of the ball joint stud and the edge of the grease fitting under the ball joint (A). If there is no oiler, then measure the distance between the lower surface of the lever and the upper part of the ball joint of the lever (IN) (see photo).

5. Remove the jack and repeat the measurement.

6. If the difference between these two sizes exceeds 2.4mm (3/32"), the ball joint is worn out and must be replaced with a new one.

7. Raise the front of the car and place it on stands. Remove the front wheel.

Rear wheel drive models (top ball joint)

8. Remove the brake caliper, move it aside and secure (see Chapter 9).

9. Unpin and unscrew the nut from the ball joint of the lever two turns.

10. Place a jack under the lower arm.

Attention! The jack must remain under the arm during the removal and installation of the ball joint of the arm in order to absorb the force from the suspension spring.

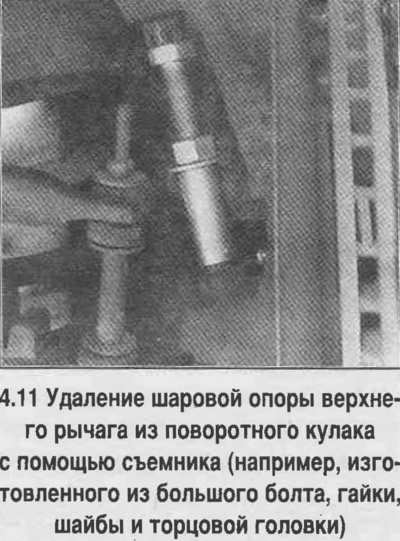

11. Press the ball bearing of the lever out of the steering knuckle with a puller (see photo).

Attention! Do not use a fork puller to avoid damage to the rubber boot of the ball joint.

12. To remove the upper ball joint from the arm, drill out the rivets (see photo). Remove the ball joint and clean the lever. Install the new upper ball joint in place and secure with nuts and bolts from the kit (see photo).

Rear wheel drive models (lower ball joint)

13. Remove the lower suspension arm (see below) and hand it over to a car service for pressing out and installing a new ball joint.

Rear wheel drive models (upper or lower control arm ball joints)

14. Clean the dirt from the edges of the taper holes in the steering knuckle. Check up a condition of eyes of fastening of spherical support. If deformation or other damage is found, replace the steering knuckle with a new one (see below).

15. Attach the ball bearings of the lever to the steering knuckle, tighten the nuts to the specified torque.

16. If the cotter pin does not align with the slot in the nut, tighten the nut to allow the cotter pin to be inserted.

17. Replace the grease fittings and lubricate the new ball joint.

18. Install wheels and remove vehicle from stands.

19. Check and, if necessary, adjust the wheel alignment.

All-wheel drive models

20. Procedure for replacing the upper ball joint on all-wheel drive models.

It is no different from the one discussed above for rear-wheel drive models. The procedure for replacing the lower ball joint is shown below.

21. Raise the vehicle and place it on stands.

22. Remove the wheel.

23. Turn away bolts of the forward mudguard panel. Move the screen aside and secure to gain access to the tie rod end.

24. Disconnect the side link from the main tie rod.

25. Remove the half shaft (see Chapter 8).

26. Apply punching centers on each rivet.

27. Drill a pilot hole with a diameter of 3.3 mm and a depth of 12.5 mm in the heads of the rivets.

28. Using a 8 mm drill, drill out the heads of the rivets. Drill out two thirds of the length of the rivet shank using the same bit.

29. Knock out the rivets with a hammer and beard.

30. Unfasten the ball joint nut.

31. Jack up the lower arm.

32. Loosen the ball joint nut by backing out a few turns.

33. Loosen the torsion bar adjuster locking bolt to reduce the load on the stabilizer bar. Do not loosen the bolt completely!

34. Separate a rotary fist from a spherical support of the lever by means of a fork puller.

35. Turn away a nut and remove a spherical support from the bottom lever.

36. Install a new support in the lever. Install the nuts and bolts of the support and tighten them to the specified torque.

37. Raise the lower arm with a jack and insert the ball joint pin of the arm into the steering knuckle. Lower the jack so that the support pin enters the eye of the steering knuckle, then wrap the nut and tighten it to the specified torque. Fasten the nut with a new cotter pin, bend the ends of the cotter pin.

38. Load the torsion bar (see below).

39. Install the axle shaft.

40. Connect the side rod to the main steering rod, tighten the tie rod end nut and tighten to the specified torque.

41.Install the front mudguard.

42. Install the wheel.

43. Lower the car.

44. Final tighten the wheel nuts.