Rear wheel drive models

1. Raise the front of the car and place it on stands. Remove the wheel.

2. Remove suspension spring.

3. Disconnect the lower ball joint.

4. Hand over the lever to a car service to replace the ball joint and bushings.

5. Installation is carried out in the reverse order. Install the lever axle bolts from the front, finally tighten the bolts after removing the vehicle from the stands. Tighten all nuts to specified torques. Lubricate the new ball joint.

All-wheel drive models

6. Raise the front of the car and place it on stands. Remove the wheel.

7. Remove the dirt-protective panel of a wheel arch for access to details of a forward suspension bracket.

8. Disconnect the stabilizer bar from the lower arm. -

9. Remove shock absorber.

10. Disconnect the side link from the main tie rod.

11. Remove the axle shaft.

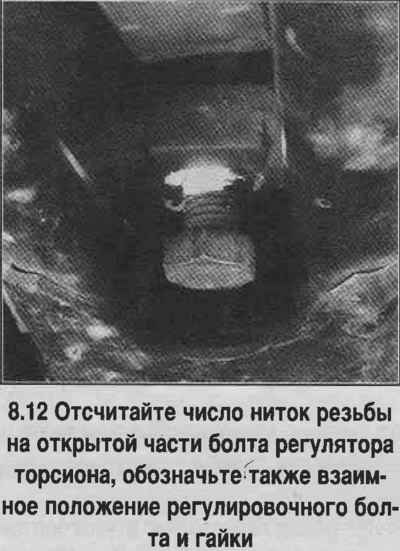

12. Count the number of threads on the open part of the torsion bar adjuster bolt, also mark the relative position of the nuts.

13. Loosen the torsion bar adjusting bolt as much as possible without completely unscrewing the bolt. This will reduce the load on the stabilizer bar.

14. Jack up the lower arm. The jack head must be installed as close to the ball joint as possible to still allow access to the ball joint stud nut.

15. Disconnect a rotary fist from the bottom spherical support of the lever. Remove the steering knuckle and hub assembly, then insert a piece of wood between the upper arm and frame.

16. Mark the position of the torsion bar relative to the lower arm, then slowly lower the jack until the force from the torsion bar disappears.

17. Move the torsion beam forward, removing it from the adjustment lever (see photo).

18. Turn away bolts and nuts of an axis of the bottom lever, remove washers (see photo). Remove the lower control arm assembly with the torsion beam.

19. Mark the protruding part of the torsion beam with adhesive tape to ensure correct installation, then remove the torsion beam from the suspension arm.

20. Check up a condition of plugs. On some models, the bushings are welded in place and cannot be removed. If the bushings are worn, the lever should be replaced. On car parts, bushings are removed and installed on a hydraulic press in a car service.

21. Insert the torsion beam into the hole in the lower arm. Raise the lever assembly with the beam and install the crossbars in the hole (if necessary, move the beam in the lever slightly forward). Install the lower arm into the frame bracket by inserting the front of the arm first.

22. Wrap bolts of an axis of the lever. From must be inserted so that the heads of the bolts are facing towards the front of the car. Install the washers, tighten the nuts, but do not completely tighten them.

23. Move the torsion beam back by inserting it into the adjusting lever.

24. Carefully raise the lower arm with a jack and insert the pin of the ball joint of the arm into the lug of the steering knuckle. Screw on the ball joint nut of the lever, tighten it to the specified torque and cotter with a new cotter pin.

25. Tighten the torsion beam adjusting nut until the distance between the cross member and the end of the adjusting arm is the same as before removal.

26. Install the axle shaft.

27. Connect the side link to the main tie rod.

28. Install shock absorber.

29. Attach the stabilizer bar to the lower arm.

30. Install the wheel and lower the car.

31. Final tighten the wheel nuts.

32. Install the front mudguard.

33. Measure the height of the vehicle on each side from equal points on the frame to the ground. If the side on which the work was carried out is higher or lower than the other side, then set the car horizontally by turning the torsion beam adjusting bolt. Usually adjustment is achieved after several attempts. When making adjustments, roll the vehicle back and forth, load and unload the front of the vehicle to «besiege» suspension details.