2. Loosen the nuts on the brake lines on the master cylinder (see photo).

3. Turn away bolts of fastening of the shut-off valve/drain cock, remove an arm. Disconnect the brake lines from the master cylinder and plug the holes to prevent dirt from entering.

4. Unscrew the two nuts securing the master cylinder, move aside the bracket with the shut-off valve and drain cock (see photo). Remove the master cylinder.

5. Remove the tank cap and diaphragm, drain the remaining liquid.

6. Install the master cylinder in a vise.

7. Remove the retaining ring of the primary chamber piston by depressing the piston and prying the ring with a screwdriver (see photo).

8. Remove the primary chamber piston with spring from the cylinder (see photo).

9. Remove the secondary chamber piston from the cylinder. If necessary, turn the cylinder over and remove the piston by tapping it on a block of wood (see photo).

10. Pry and remove the tank from the cylinder body (see photo). Remove seals.

11. It is not allowed to remove the bypass valve from the cylinder body, since this device is non-separable and cannot be serviced.

12. Check up a condition of the cylinder. If any damage is found, replace the master cylinder. Grinding of the inner surface is not allowed.

13. Lubricate the new reservoir seals with brake fluid and press them into the cylinder body. Make sure the seals are in place.

14. Lay the reservoir on a hard surface and push it into the master cylinder body (see photo).

15. Remove old secondary piston seals and install new seals with lips facing away from each other (see photo). The main piston seal of the secondary chamber should be oriented as shown in the photo.

16. Install a new spring thrust washer on the piston of the secondary chamber (see photo).

17. Lubricate the cylinder with clean brake fluid and install the secondary chamber spring and piston with seals (see photo).

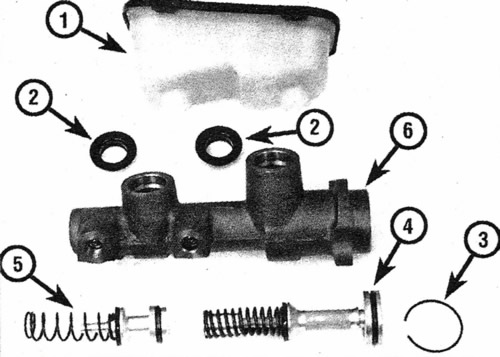

8.17. Parts of the brake master cylinder.

1. Nutrient tank with lid, diaphragm

2. Seals

3. Retaining ring

4. Primary chamber piston with spring

5. Secondary piston with spring

6. Body

18. Install the piston of the primary chamber with a spring into the cylinder, wring out the piston and insert the retaining ring.

19. Check reservoir cap and diaphragm. If cracks or deformations are found, replace the tank. Attach the diaphragm to the reservoir lid.

20. Before installation on the car, remove the air from the cylinder, which will speed up the pumping of the brakes and save fluid.

21. Clamp the cylinder in a vise, pour fluid into the reservoir, tighten the plugs and press the primary chamber piston with a large Phillips screwdriver. Open the plug to let the air out. Close the plug and release the piston. Repeat these steps until fluid begins to come out of the fitting hole. Maintain the fluid level in the reservoir at all times. Repeat the bleed steps for the other hole.

22. Instead of a plug, you can close the hole with your finger. Release your finger after pressing the pistons, after fluid flows out, close the hole with your finger and release the pistons. After a few seconds, press the plunger again and remove your finger. Repeat the procedure and do the same for the other hole. After only liquid begins to flow out of the holes, wrap the plugs.

24. Install the cylinder in reverse order. First tighten both nuts by hand. Screw the fittings without distortions, manipulating the cylinder. Tighten nuts and fittings.

25. When finished, bleed the air from the hydraulic brakes.