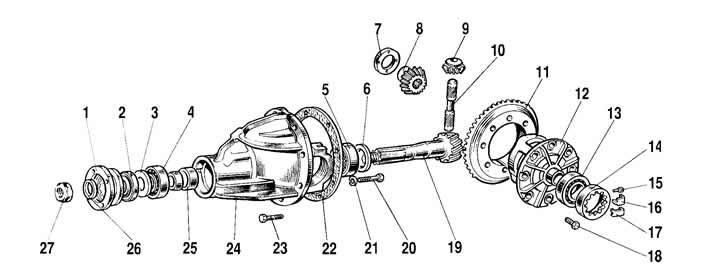

Gearbox details are shown in fig. 3-63.

Pic. 3-63. Rear axle gear details:

1 - drive gear flange;

2 - stuffing box;

3 - oil deflector;

4 - front bearing;

5 - rear bearing;

6 - adjusting ring of the drive gear;

7 - support washer of the axle gear;

8 - axle gear;

9 - satellite;

10 - axis of the satellites;

11 - driven gear;

12 - differential box;

13 - differential box bearing;

14 - adjusting nut;

15 - a bolt of fastening of a locking plate;

16 - locking plate;

17 - locking plate;

18 - a bolt of fastening of a driven gear;

19 - drive gear;

20 - cover fastening bolt;

21 - spring washer;

22 - gasket;

23 - gearbox mounting bolt;

24 - gearbox housing;

25 - spacer sleeve;

26 - flat washer;

27 - nut for fastening the drive gear flange.

Differential assembly. Lubricate with gear oil and install through the windows in the differential box the gears of the axle shafts with support washers and satellites. Turn the satellites and gears of the axle shafts so as to align the axis of rotation with the axis of the hole in the box, then insert the axis of the satellites.

Check the axial clearance of each axle gear: it should be 0-0.10 mm, and the moment of resistance to rotation of the differential gears should not exceed 14.7 Nm (1.5 kgf·m).

If the clearance is increased, which is a sign of wear of the differential parts, replace the bearing washers of the gears of the axle shafts with others of greater thickness. If the specified clearance cannot be obtained even with the thickest washer installed, replace the gears with new ones due to excessive wear.

Attach the driven gear to the differential case.

Using mandrel A.70152, press the inner races of roller bearings onto the differential box.