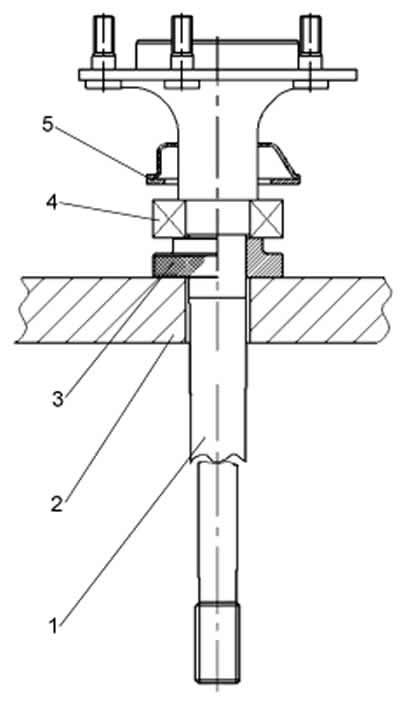

Pic. 3-56. Pressing the bearing and the locking ring of the axle shaft bearing:

1 - axle shaft;

2 - press table;

3 - ring from the tool kit 67.7853.9571;

4 - bearing;

5 - bearing mounting plate and oil deflector assembly.

Insert a new locking ring into a special holder, put it in an oven and heat the ring to approximately 300°C so that at the time of pressing onto the axle shaft its temperature is 220-240°C.

Press the locking ring on the axle shaft on the press with a force not exceeding 58.8 kN (6000 kgf) so that the inner ring of the bearing is sandwiched between the locking ring and the shoulder of the axle shaft.

After pressing on, make sure that the ring does not move under an axial load of 19.6 kN (2000 kgf). For this purpose, install the axle shaft assembly on a special tool (pic. 3-57), and clamp the locking ring in a special vise.

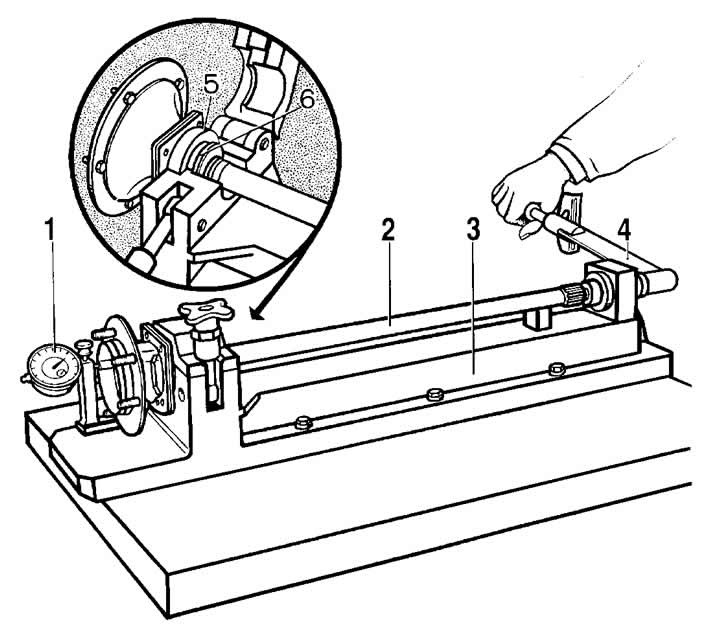

Pic. 3-57. Checking the force of pressing out the locking ring of the axle shaft bearing:

1 - indicator;

2 - axle shaft;

3 - fixture;

4 - torque wrench;

5 - bearing;

6 - locking ring of the bearing.

Attach indicator leg 1 with a division value of 0.01 mm to the axle shaft flange. After setting the indicator pointer to «0» apply the specified axial load, applying a tightening torque of 78.5-83.3 Nm with a torque wrench (8-8.5 kgf·m) on the fixture screw. The screw through the ball rests against the end of the axle shaft. In this case, even the smallest gap between the locking ring and the inner ring of the bearing should not appear.

After removing the load and when the screw of the device is unscrewed, the indicator arrow should return to the zero position; this proves that no shift has occurred between the snap ring and the axle shaft. If the indicator needle does not return to the zero position, then the locking ring has shifted and the axle shaft assembly must be replaced with a new one.

After checking the pressing of the locking ring, install the bolts for fastening the plate and the oil deflector 6 (see fig. 3-56) and fix them by bending the bolt holders inward.