Fasten the fixture to the gearbox housing with screws 1 and 6, screwing them into the holes for the bolts for fastening the locking plates of the adjusting nuts.

Move bracket 7 along the guide of the fixture until lever 5 touches the outer side surface of the cover and tighten screw 8.

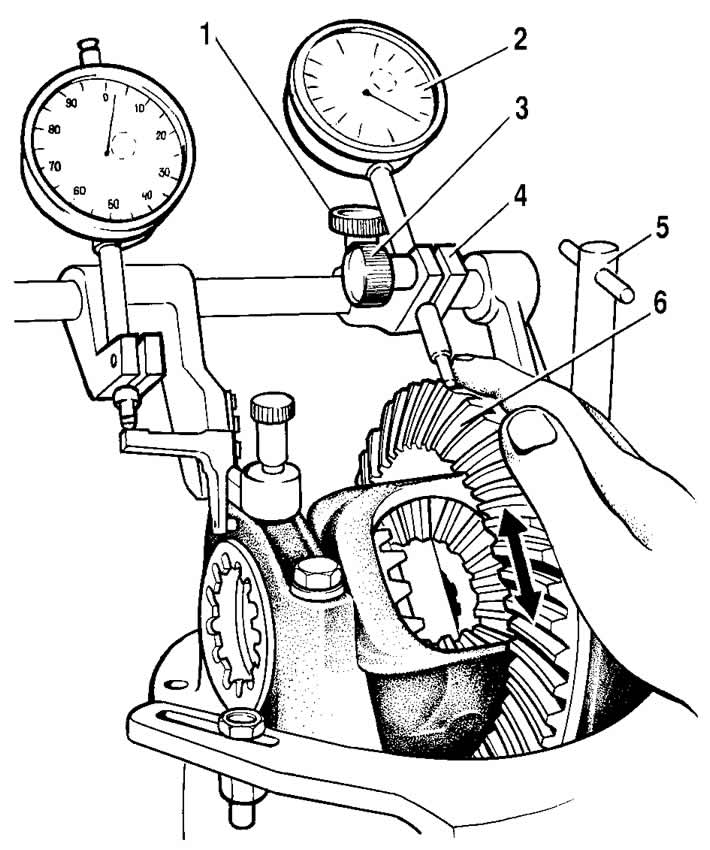

Loosen screws 1 and 3 (pic. 3-72) and install the bracket 4 so that the indicator leg 2 rests on the side surface of the driven gear tooth at the edge of the tooth, then tighten the screws 1 and 3.

Pic. 3-72. Checking the side clearance in the gearing of the final drive gears using A.95688 / P:

1 - bracket mounting screw;

2 - indicator for checking the side clearance in the meshing of gears;

3 - screw for fastening the indicator rod;

4 - indicator bracket;

5 - fastening screw;

6 - driven gear.

By turning the adjusting nuts, pre-adjust the backlash between the teeth of the driving and driven gears within 0.08-0.13 mm. The gap is checked by indicator 2 while rocking gear 6. In this case, the bearings should not have a preload. The adjusting nuts must only be in contact with the bearings, otherwise the correct preload measurement will be impaired.

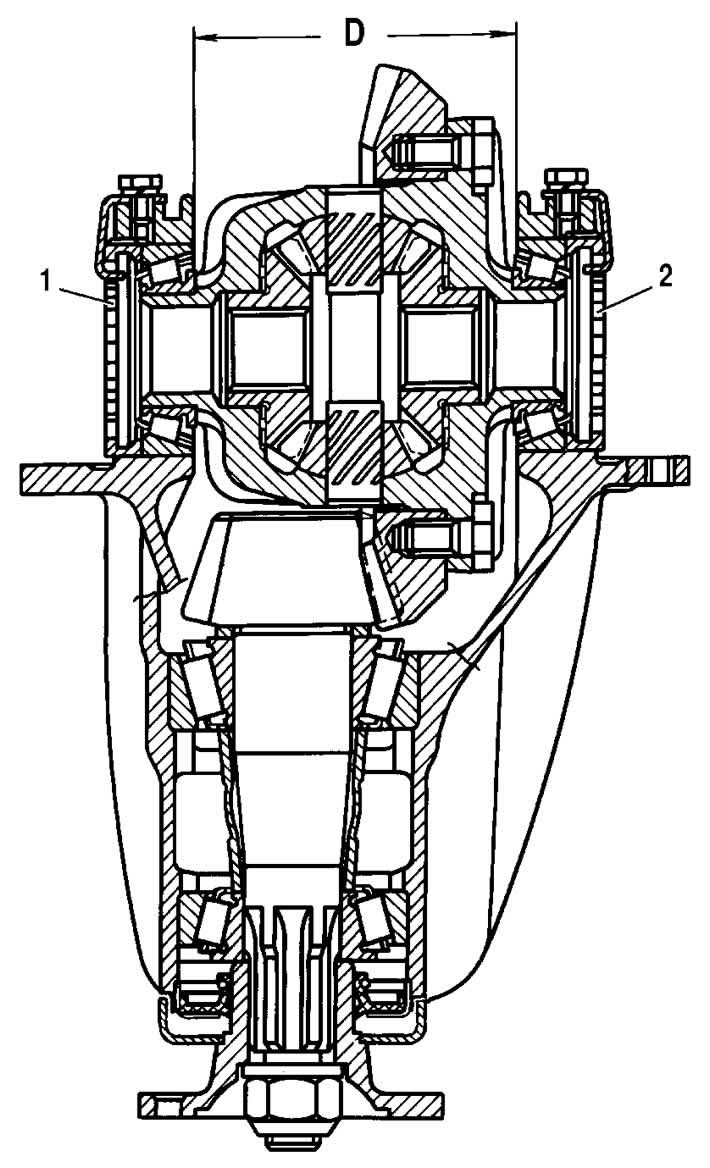

Tighten the two bearing adjusting nuts sequentially and evenly, this will cause the differential bearing caps to move apart and thus increase the distance «D» (pic. 3-73) by 0.14-0.18 mm.

Having set the exact preload of the bearings of the differential box, finally check the backlash in the meshing of the final drive gears, which should not change.

If the gap in the meshing of the gears is more than 0.08-0.13 mm, then move the driven gear closer to the drive gear or move it away if the gap is smaller. To maintain the set bearing preload, move the driven gear by tightening one of the bearing adjusting nuts and loosening the other by the same angle.

Pic. 3-73. Scheme for checking the preload of differential box bearings:

D is the distance between the two differential bearing caps;

1, 2 - adjusting nuts.

To accurately perform this operation, watch the indicator 9 (see fig. 3-71), which shows the previously set bearing preload. After tightening one of the nuts, the indicator reading will change as the discrepancy increases «D» (see fig. 3-73) caps and bearing preload. Therefore, loosen the other nut until the indicator needle returns to its original position.

After moving the driven gear, according to the indicator 9 (see fig. 3-71) check the side clearance. If the clearance is not correct, repeat the adjustment.

Remove tool A.95688/R, fit the locking plates of the adjusting nuts and secure them with bolts and spring washers. Two types of locking plates are available as spare parts: with one or two tabs, depending on the position of the nut slot.

The adjustment and repair of the gearbox units is carried out on the stand, where you can also test the gearbox for noise and check the location and shape of the contact patch on the working surfaces of the teeth, as indicated below.