The deformation of the bridge beam is checked both in the horizontal and vertical planes.

Having attached a flange A.70172 to each end of the beam, install the beam with flanges on identical prisms located on a test plate with a length of at least 1600 mm so that the crankcase contact surface to the beam is in a vertical plane.

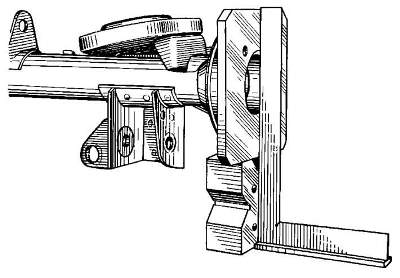

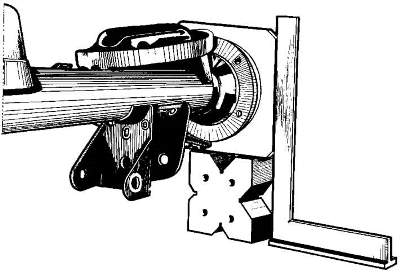

Check the deformation of the beam by attaching a square to the outer (pic. 3-50) and side (pic. 3-51) flange surfaces A.70172; if the beam is not deformed, the square will fit snugly.

Pic. 3-50. Checking the vertical deformations of the rear axle beam with a square on the outer surface of the flange A.70172.

Pic. 3-51. Checking the twisting of the rear axle beam with a square on the side surface of the flange A.70172.

The amount of deformation is checked with a feeler gauge. If the 0.2 mm feeler gauge passes through any flange, the beam must be straightened.

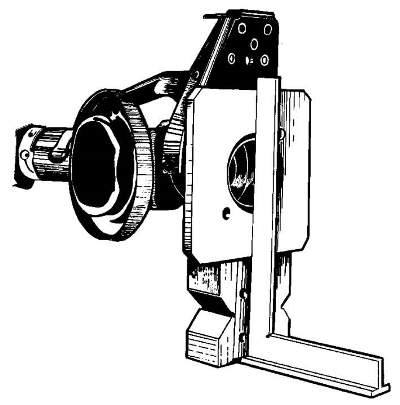

square (pic. 3-52) check the perpendicularity of the mounting surface of the gearbox relative to the bearing surface of the flange A.70172. The 0.2 mm probe must not pass through.

Pic. 3-52. Checking the perpendicularity of the gearbox mounting surface.

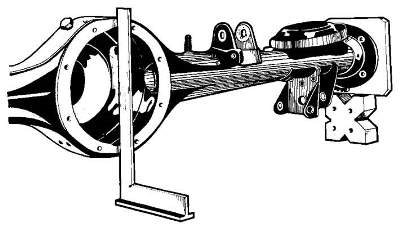

Rotate the bridge beam 90°and place it on the prisms. Applied to the outer surface of the flange (pic. 3-53) the square must fit snugly, otherwise check the amount of deformation with a feeler gauge. The 0.2 mm probe must not pass through.

Pic. 3-53. Checking the horizontal deformations of the rear axle beam with a square on the outer surface of the flange A.70172.

If the deformation exceeds the specified value, straighten the beam, following the instructions below.

After making adjustments, rinse the beam thoroughly, clean the magnetic plug, put it back in place and check:

- the quality of the welds and the tightness of the beam;

- cleanliness inside the beam (free of burrs, chips and oil residues) and cleanliness of the beam breather.

After that, paint the outside of the beam to protect it from corrosion.