Unscrew handle 5 (pic. 3-8) from gear lever 6 and remove cover 7.

Loosen the bolts securing the front propeller shaft to the flanges of the front axle gearbox and transfer case and remove the front propeller shaft.

Disconnect the pipe suspension and mufflers at the rear of the vehicle, and then the converter flange from the front pipe and remove the converter, additional and main muffler as an assembly. Bend back the edges of the locking plates and unscrew the nuts securing the exhaust pipe to the exhaust manifold. Remove the crankcase protection and engine mudguard. Unscrew the oxygen sensor on the downpipe. Loosen the stabilizer mounting nuts and remove the stabilizer. Turn away a nut of fastening of a reception pipe to a supporting arm and remove a reception pipe downwards.

Disconnect the wires from the reversing light switch.

Disconnect the slave cylinder from the clutch housing. In this case, the cylinder connected to the pipeline going to the master cylinder of the clutch release actuator remains on the vehicle, which eliminates the loss of brake fluid and the need for subsequent bleeding of the hydraulic clutch release actuator.

Unscrew the bolts securing the starter to the clutch housing with a swivel socket wrench and release it. Loosen the clutch housing cover bolts.

Install the clamping collar A.70025 on the flexible coupling and tighten it. This will facilitate the removal and subsequent installation of the flexible coupling. Turn away nuts and, scrolling an intermediate cardan shaft, remove bolts of fastening of an elastic coupling to a flange of a secondary shaft of a transmission. Turning the intermediate cardan shaft, unscrew the nuts of the studs securing the shaft to the transfer case flange. Move the clutch in the shaft spline back relative to the gearbox flange until the centering ring comes out of the clutch hole and remove the intermediate cardan shaft.

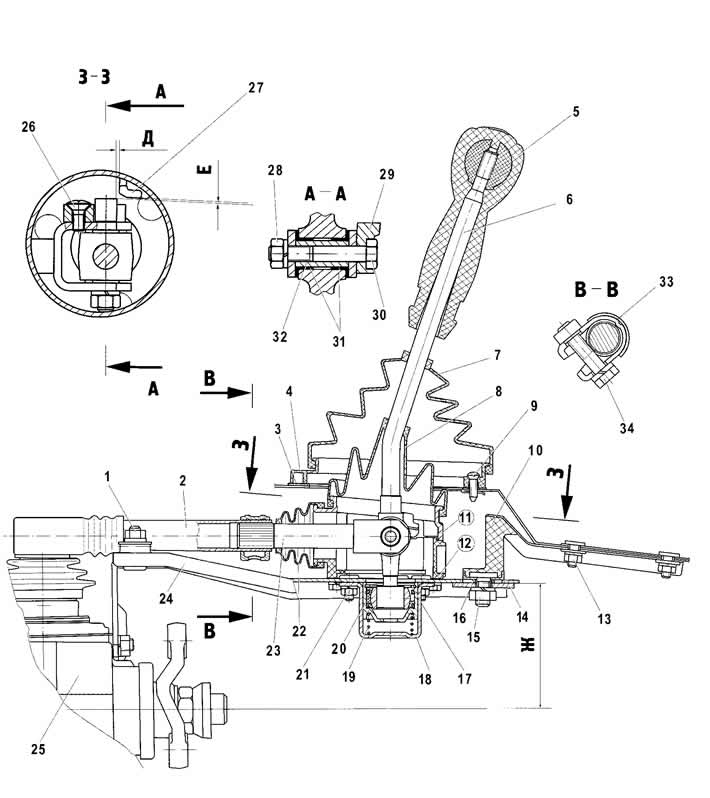

Pic. 3-8. Gear selector control drive:

1 - nut for fastening the base plate;

2 - thrust of the gearbox control drive;

3 - manhole cover gasket;

4 - hatch cover of the gear lever;

5 - gear lever handle;

6 - gear lever;

7 - a cover of the gear lever;

8 - sealing case;

9 - screw securing the hatch cover;

10 - rear support;

11 - gear lever housing;

12 - lower housing of the gear lever;

13 - nuts for fastening the rear support;

14 - rear support washer;

15 - nut;

16 - spacer ring;

17 - retaining ring;

18 - body of the ball bearing;

19 - spring of the gear lever;

20 - ball bearing slider;

21 - nuts for fastening the body of the ball joint;

22 - protective cover;

23 - thrust tip;

24 - support plate;

25 - gearbox;

26 - screw for fastening the blocking stop;

27 - overlay of blocking of a backing;

28 - a nut of a bolt of fastening of a tip of draft;

29 - blocking emphasis;

30 - a bolt of fastening of a tip of draft;

31 - bushings;

32 - remote bushing;

33 - control drive rod clamp;

34 - clamp bolt.

Unscrew the nut 15 connecting the base plate 24 of the control drive with the rear support 10.

Detach the engine rear mount from the cross member, and then remove the cross member while supporting the gearbox from below.

Remove the gearbox control drive, for which:

- unscrew the three nuts securing the bracket to the rear cover of the gearbox 25;

- after loosening the clamp fastening bolt 34, disconnect the control drive rod;

- remove the gearbox control drive.

Place a jack, stands or other suitable support under the gearbox housing. Using a socket wrench, unscrew the engine mounting bolts and remove the gearbox together with the clutch housing, shifting it to the rear of the car so as to remove the gearbox input shaft from the front bearing and from the driven disk hub.

Warning. When removing or installing the gearbox, it is forbidden to rest the end of the input shaft on the petals of the clutch pressure spring, so as not to deform the clutch pressure spring.

The gearbox is installed in the reverse order of removal. Before installation, clean and flush with white spirit the splines on the input shaft of the gearbox and the hub of the clutch disc, center the clutch disc with the mandrel A.70081 (see fig. 3-3).

After installation on the clutch housing, apply DT-1 grease to the spherical surface of the clutch actuator cylinder pusher.

Check the level and, if necessary, add oil to the gearbox housing. The oil level should be at the bottom edge of the filler hole.