Remove the clutch release fork, and remove the clutch release assembly from the guide sleeve of the front cover of the gearbox.

Remove the clutch housing with gasket and the front cover of the gearbox along with the oil seal and spring washer (see fig. 3-9).

Unscrew the reversing light switch, being careful not to deform its housing.

Turn out a bolt of fastening of a plug of switching of III and IV transfers. Install clamp 41.7816-4070 on the input shaft or simultaneously engage two gears. This will prevent rotation of the input, output and intermediate shafts and allow subsequent disassembly operations.

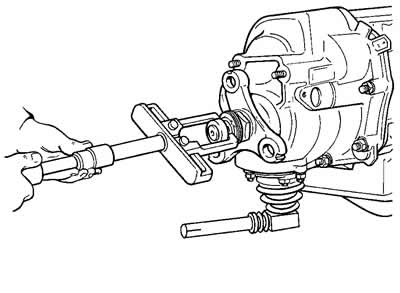

Loosen the nut 28 (see fig. 3-7) a few turns to move the centering ring 30 of the flexible coupling, and tighten the nut 28 again. Using a puller, remove the centering ring of the flexible coupling of the cardan shaft from the end of the secondary shaft (pic. 3-10).

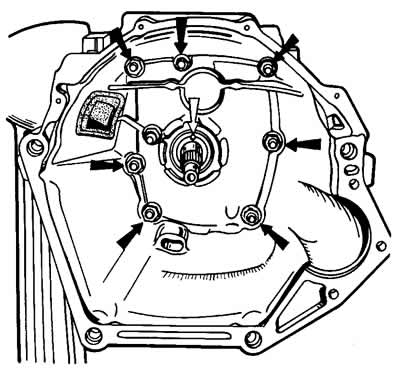

Pic. 3-9. Interior view of the clutch housing

Black arrows indicate the nuts securing the clutch housing to the gearbox; the white arrow indicates the hole in the front cover to drain the oil from the gearbox housing so that the clutch discs do not get oiled.

Pic. 3-10. Removing the centering ring of the flexible coupling of the cardan shaft.

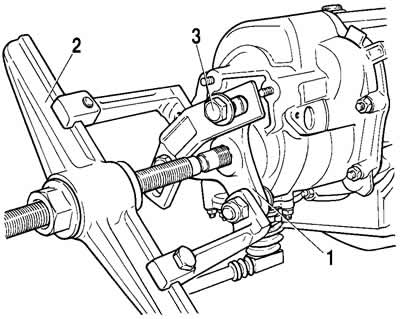

Remove the seal 29 of the centering ring of the elastic coupling from the end of the secondary shaft, unscrew the nut 28 and remove the flexible coupling flange with a puller (pic. 3-11).

Remove the gear selector before removing the rear cover. To do this, remove the drive rod collar 33 (see fig. 3-8), unscrewing the bolt 34. Then, unscrewing the fastening nuts 21 (see fig. 3-7), remove the gear selector assembly.

Unscrew the six rear cover fastening nuts 36, one of the rear cover fastening nuts is unscrewed from the inside of the gearbox housing with the bottom cover removed. When removing the rear cover, it must be fed not only back, but also rotated to prevent it from touching the reverse gear and fifth gear.

Pic. 3-11. Removing the flexible coupling flange with a puller:

1 - flange of an elastic coupling;

2 - puller;

3 - bolts for fastening the puller to the flange.

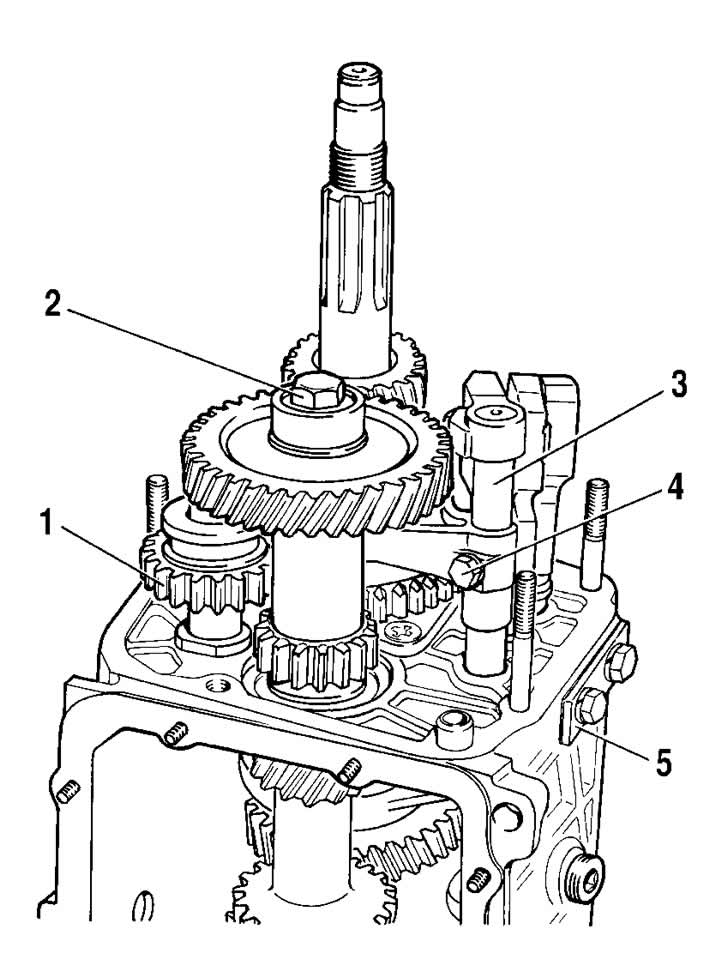

After removing the inner ring of the rear bearing 32 and the bearing spacer 33 from the secondary shaft, loosen the bolts securing the clamp cover 5 (pic. 3-12) and unscrew bolts 2 and 4 fastening the gear unit and the fork for engaging the fifth gear and reverse. Remove oil deflector 26 (see fig. 3-7) and remove stem 1 (pic. 3-13) from the fork 2. At the same time, the distance sleeve 3 is removed from the rod. Then remove the gear unit 4 from the spline of the intermediate shaft.

Remove intermediate gear 1 at the same time (pic. 3-14) reverse gear from the axle, gear 3 complete with clutch and fork 4 from the secondary shaft. Then remove the thrust washer and retaining ring.

Pic. 3-12. Unscrewing the bolts of the gear unit and the fork for engaging the V gear and reverse gear:

1 - intermediate reverse gear;

2 - a bolt of fastening of the gear block;

3 - plug stem;

4 - fork fastening bolt;

5 - clamp cover.

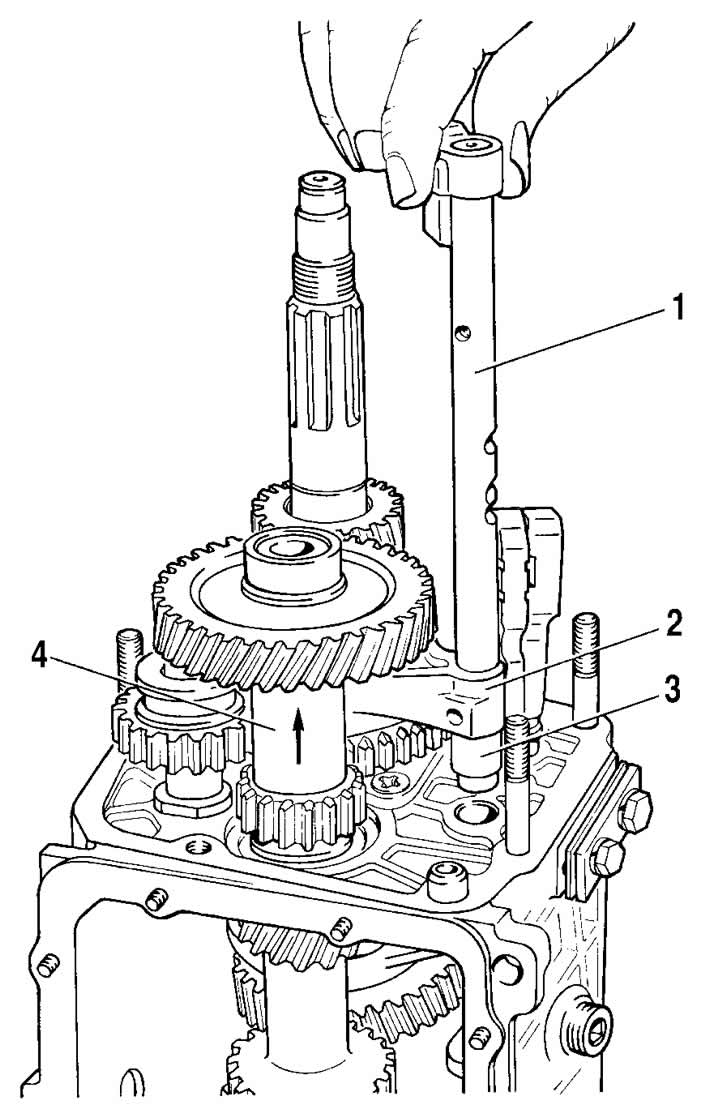

Pic. 3-13. Removing the fork rod of the V gear and reverse gear:

1 - fork rod for engaging V gear and reverse gear;

2 - fork for switching on V gear and reverse gear;

3 - remote bushing;

4 - gear block.

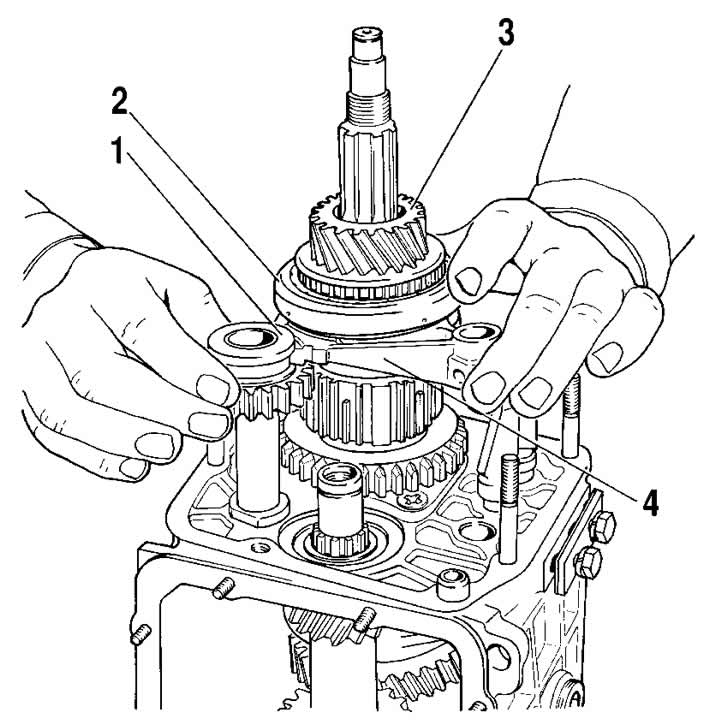

Pic. 3-14. Removing the reverse gear, V gear assembly with synchronizer and fork:

1 - intermediate reverse gear;

2 - 5th gear engagement clutch;

3 - gear V gear and reverse;

4 - fork for switching on V gear and reverse gear.

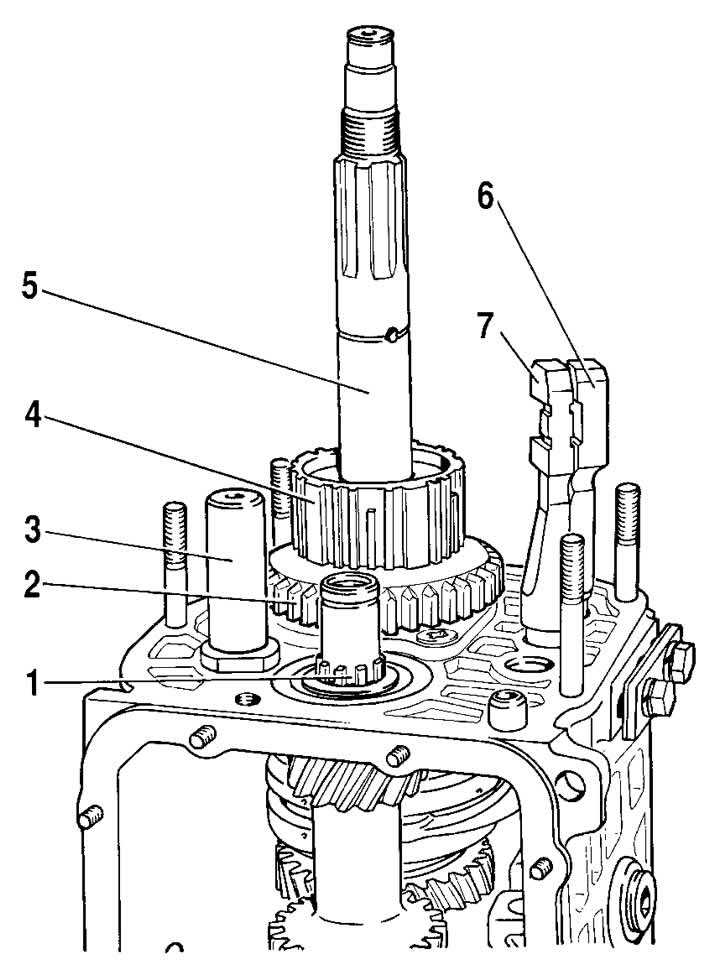

Remove hub 4 (pic. 3-15) 5th gear synchronizer, spring washer and reverse driven gear 2.

Pic. 3-15. Removing the reverse driven gear and the 5th gear synchronizer clutch hub:

1 - intermediate shaft;

2 - reverse driven gear;

3 - axis of the intermediate reverse gear;

4 - hub of the synchronizer clutch of the V transmission;

5 - secondary shaft;

6 - a rod of a fork of inclusion of I and II transfers;

7 - rod of the fork of inclusion of III and IV gears.

Using figured mandrels and rod drifts, remove the front and rear intermediate shaft bearings from the gearbox housing. On the inner rings of a double-row bearing, put marks on which these rings should be installed in their original places in the outer ring of the bearing.

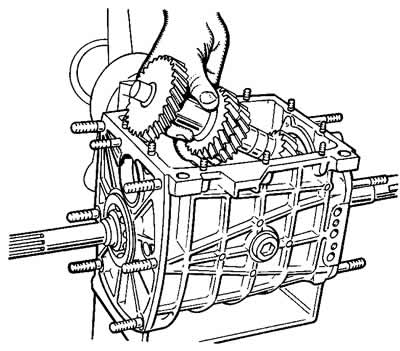

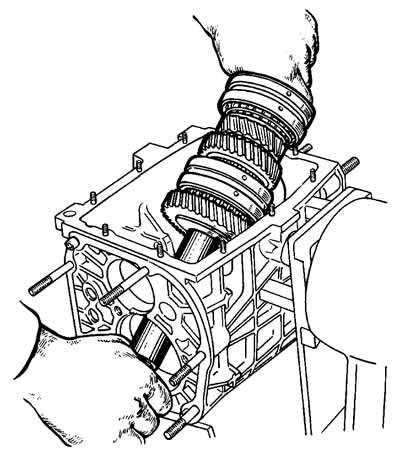

Remove the intermediate shaft from the gearbox housing by tilting it as shown in fig. 3-16.

Pic. 3-16. Removing the intermediate shaft from the gearbox housing.

Remove from the gearbox housing one by one the rods of the shift forks of I, II, III and IV gears, having previously unscrewed the bolts of the forks. When removing the rods, simultaneously remove the three blocking crackers 6 (pic. 3-17). Remove lock plate (pic. 3-18) output shaft intermediate bearing. Loosen the reverse idler gear axle nut and remove it.

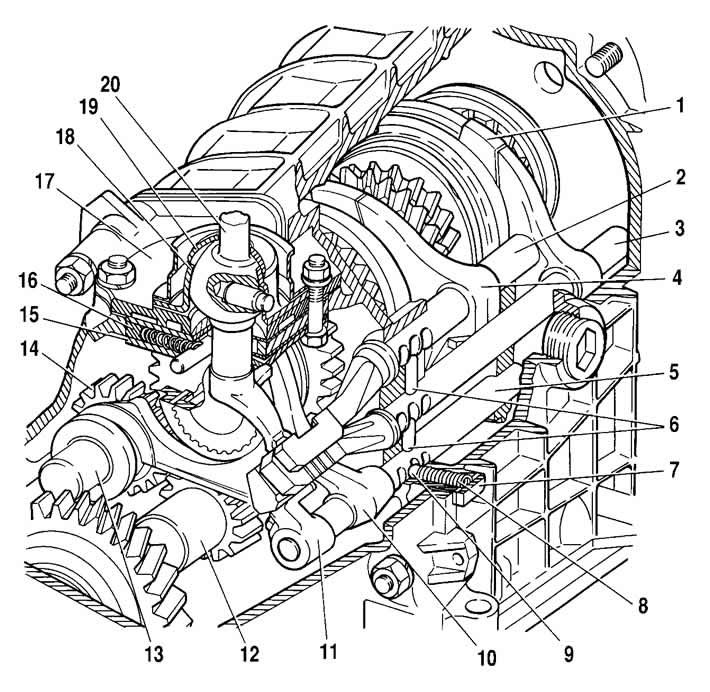

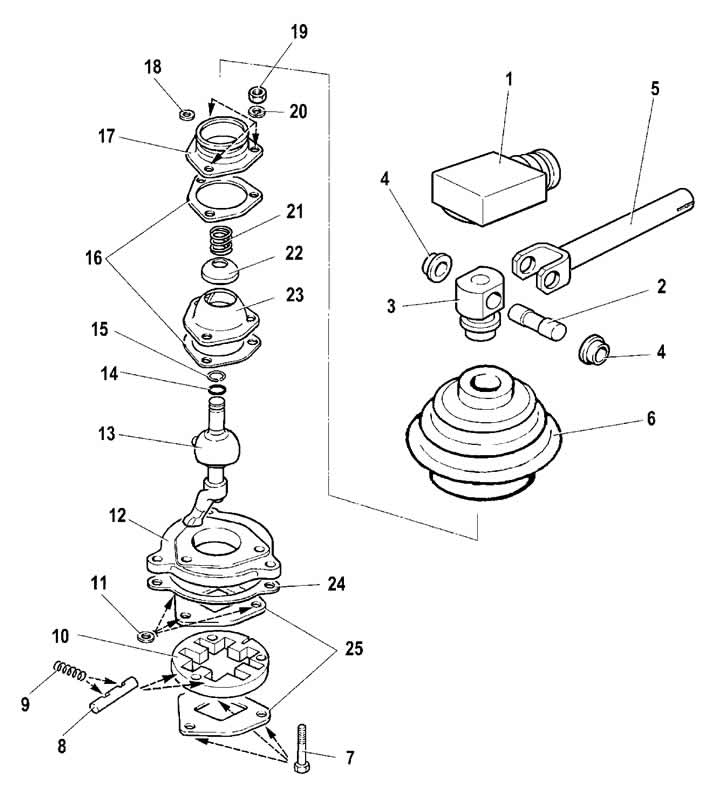

Pic. 3-17. Gear selection drive:

1 - fork of inclusion of III and IV gears;

2 - a rod of a fork of inclusion of I and II transfers;

3 - rod of the fork of inclusion of III and IV gears;

4 - fork of inclusion of I and II transfers;

5 - rod of the fork for engaging the V gear and reverse gear;

6 - block crackers;

7 - cover of clamps;

8 - spring clamps;

9 - a ball of clamps;

10 - fork for switching on V gear and reverse gear;

11 - head of the fork of the V gear and reverse gear;

12 - a block of gears of V gear and reverse;

13 - axis of the intermediate reverse gear;

14 - intermediate reverse gear;

15 - washer of the guide plate;

16 - guide plate;

17 - gear selector lever housing;

18 - ball bearing;

19 - spherical washer of the ball bearing;

20 - gear selection lever.

Pic. 3-18. Unscrewing the screws securing the locking plate of the intermediate bearing of the secondary shaft with a drill screwdriver.

The arrow shows the direction of the impact stroke of the screwdriver holder when struck with a hammer.

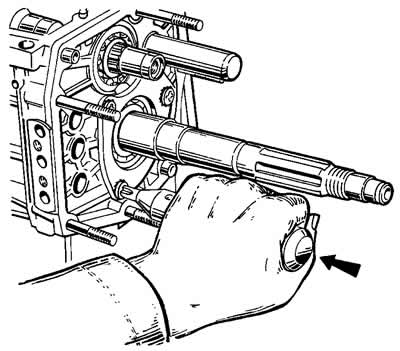

Using drifts, remove the input shaft along with the bearing and synchronizer ring (pic. 3-19) and remove the needle bearing from the front end of the output shaft.

Pic. 3-19. Removing the input shaft from the gearbox housing.

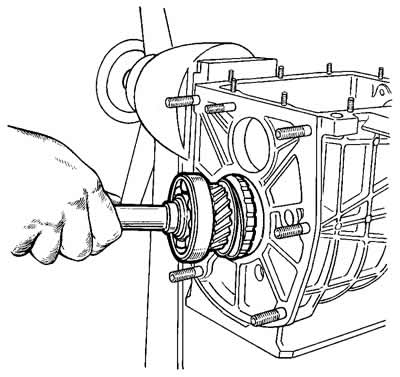

Knock out the secondary shaft from the intermediate bearing, remove the intermediate bearing and, tilting as shown in fig. 3-20, remove the output shaft assembly with gears, clutches and synchronizer rings from the crankcase. Remove the 3rd and 4th gear synchronizer coupling from the shaft.

Pic. 3-20. Removing the output shaft from the gearbox housing.

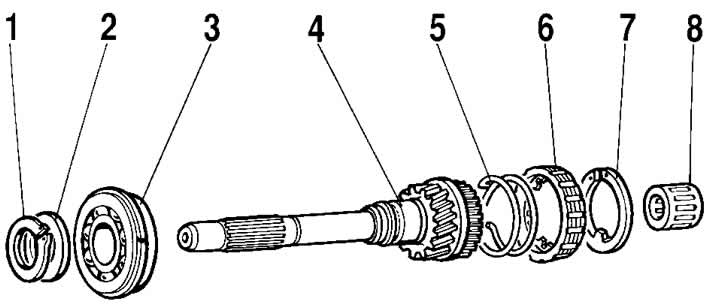

Disassemble the input shaft (pic. 3-21):

- remove the retaining ring 7, blocking ring 6 and synchronizer spring 5;

- install the shaft on the press and, compressing the spring washer 2 with the mandrel 41.7816-4069, remove the retaining ring 1, and then the spring washer and bearing 3.

Pic. 3-21. Main shaft details:

1 - retaining ring;

2 - spring washer;

3 - bearing;

4 - input shaft;

5 - synchronizer spring;

6 - synchronizer blocking ring;

7 - retaining ring;

8 - bearing.

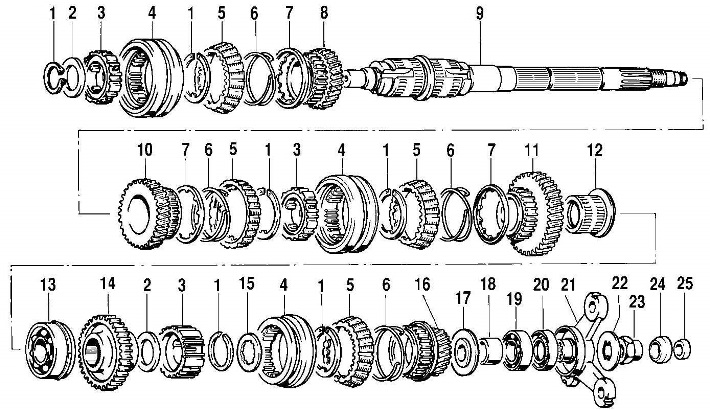

Disassemble the output shaft (pic. 3-22):

- remove from the rear side of the shaft the gear 11 of the first gear with the sleeve 12, the hub 3 with the sliding clutch 4 for switching I and II gears, the gear 10 of the second gear together with the blocking ring 5 of the synchronizer;

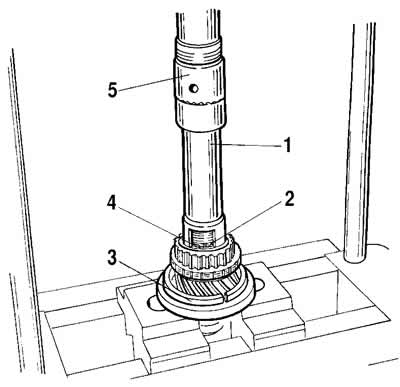

- install the output shaft with the mandrel 41.7816-4069 on the press (pic. 3-23), place support half rings 3 under the gear of the III gear and, pressing the mandrel on the spring washer, remove the retaining ring 2, then the spring washer 4, the hub of the sliding clutch of the III and IV gears and the gear of the III gear.

Pic. 3-22. Output shaft details:

1 - retaining ring;

2 - spring washer;

3 - synchronizer hub;

4 - synchronizer clutch;

5 - blocking ring;

6 - synchronizer spring;

7 - washer;

8 - gear of the III gear;

9 - secondary shaft;

10 - gear wheel of the 2nd gear;

11 - gear 1st gear;

12 - gear bushing;

13 - bearing;

14 - reverse gear;

15 - thrust washer;

16 - gear V gear;

17 - oil deflector washer;

18 - spacer sleeve;

19 - rear bearing of the secondary shaft;

20 - stuffing box;

21 - flange of an elastic coupling;

22 - lock washer;

23 - nut;

24 - sealant;

25 - centering ring.

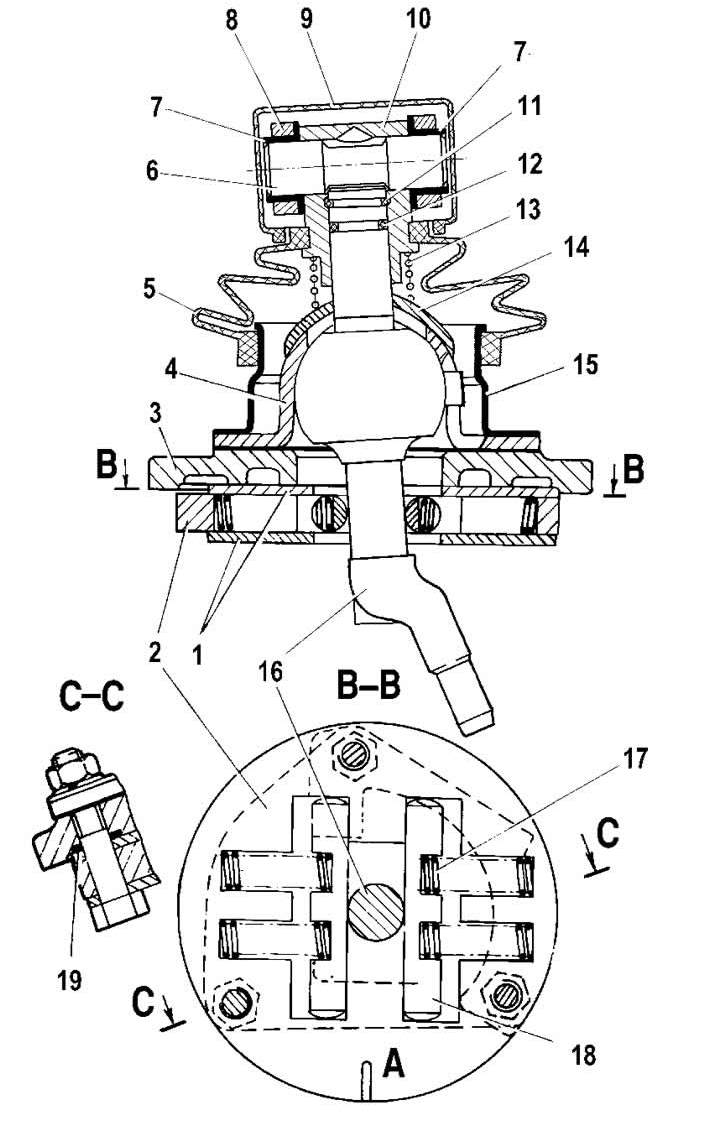

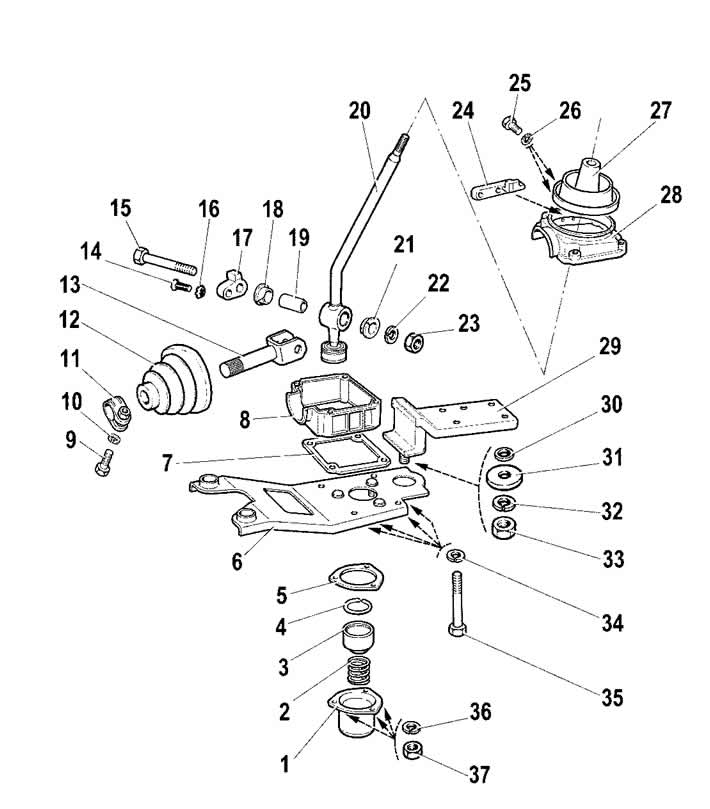

Dismantle the gear selector if necessary (pic. 3-24), For what:

Pic. 3-23. Installation on the secondary shaft of the retaining ring:

1 - mandrel 41.7816-4069;

2 - retaining ring;

3 - support half ring;

4 - spring washer;

5 - press rod.

Pic. 3-24. Gear selection mechanism:

1 - washer of the guide plate;

2 - guide plate;

3 - gear selector lever housing;

4 - ball bearing;

5 - case cover of the front hinge;

6 - thrust hinge axis;

7 - thrust eye bushing;

8 - thrust of the gearbox control drive;

9 - a cover of draft of a drive of management;

10 - body of the control drive rod hinge;

11 - retaining ring;

12 - sealing ring;

13 - spring gear selection lever;

14 - spherical washer of the ball bearing;

15 - flange;

16 - gear selection lever;

17 - spring of the guide bar;

18 - guide bar;

19 - sealing ring;

A is risk.

- remove protective covers 1 and 6 (pic. 3-25);

- pull off the rod joint housing 3 by squeezing the retaining ring 15 from the gear selection lever 13.

This will allow you to remove the hinge pin of the rod 2 and remove the drive rod 5 with two bushings 4

- remove the spring 21 and the spherical washer of the ball joint 22 from the gear selection lever 13;

- visually mark the location of the parts relative to the risk A (see fig. 3-24), printed on the guide plate, so that when assembling, connect the parts in the same position;

- having unscrewed the nuts from the fastening bolts, separate the parts of the gear selection mechanism and remove the lever 16, its ball bearing 4 and sealing rings 19.

Pic. 3-25. Gear selector details:

1 - front thrust cover;

2 - thrust hinge axis;

3 - thrust joint housing;

4 - thrust eye bushing;

5 - thrust of the gearbox control drive;

6 - cover of the front hinge housing;

7 - bolt;

8 - guide bar;

9 - spring of the guide bar;

10 - guide plate;

11 - sealing ring;

12 - gear selector lever housing;

13 - gear selection lever;

14 - sealing ring;

15 - retaining ring;

16 - ball bearing gasket;

17 - seal mounting flange;

18 - washer;

19 - nut;

20 - washer;

21 - spring;

22 - spherical washer of the ball bearing;

23 - ball bearing of the gear selection lever;

24 - gasket;

25 - guide plate washer.

Also, if necessary, disassemble the drive for controlling the gear selection mechanism, for which:

- remove protective cover 12 (pic. 3-26), remove the back-up blocking pad 24 from the lever body by unscrewing two bolts 25;

- disassemble the gear selector lever housing by unscrewing four bolts 35;

- remove the body of the ball joint 1 by unscrewing three nuts 37. Then unscrew the nut 23, remove the shaft of the gear selector lever 15 and remove the rod end 13;

- to remove the slider of the ball joint 3, remove the retaining ring 4.

Pic. 3-26. Details of the gear selector control drive:

1 - body of the ball bearing;

2 - spring;

3 - ball bearing slider;

4 - retaining ring;

5 - gasket of the body of the ball joint;

6 - base plate;

7 - gasket of the lower case;

8 - lower housing of the gear selection lever;

9 - clamp bolt;

10 - washer;

11 - a collar of draft of a drive of management;

12 - protective cover;

13 - thrust tip;

14 - screw of the blocking stop;

15 - axis of the gear selection lever;

16 - gear washer;

17 - blocking emphasis;

18 - bushing;

19 - remote bushing;

20 - gear selection lever;

21 - bushing;

22 - washer;

23 - nut of the lever axis;

24 - overlay of blocking of a backing;

25 - lining bolt;

26 - washer;

27 - sealing case;

28 - gear selector lever housing;

29 - rear support;

30 - spacer ring;

31 - rear support washer;

32 - washer;

33 - rear support nut;

34 - washer;

35 - bolt of the gear selector lever housing;

36 - washer;

37 - nut for fastening the body of the ball joint.

Assemble the gearbox in the reverse order of disassembly. In doing so, keep in mind that:

- the axis of the intermediate reverse gear is attached before the shafts are installed in the gearbox housing with a torque of 70... 80 N.m (7...8 kgf·m);

- before installing the fifth gear and reverse fork rod into the crankcase, install a distance sleeve on it;

- the inner ring of the bearing is pressed onto the gear unit of the fifth gear and reverse gear, and the outer ring into the rear cover socket;

- the secondary shaft rear bearing is pressed onto the shaft to facilitate installation of the rear cover;

- intermediate gear 1 (see fig. 3-14) reverse gear, gear 3 and fork 4 are installed at the same time;

- tighten the gear block mounting bolt with a torque of 70.80 Nm (7.8 kgf·m);

- before installation, coat the working surface of the seals with Litol-24 grease;

- when installing oil seals and bearings, use mandrels 41.7853-4028, 41.78534032, 41.7853-4039;

- when assembling the gear selection mechanism, apply Litol-24 or LSTs-15 grease on the surfaces of the gear selection lever that are in contact with the ball joint and the thrust joint housing. And also apply grease to the inner surface of the spherical washer of the ball joint;

- when assembling the drive for controlling the gear shift mechanism, apply grease LSTs-15 to the inner surface of the ball joint housing;

- when installing the gearshift control drive, holding the gearshift lever and the base plate in a relative position determined by the dimensions (see fig. 3-9) D= (1,5+0,5) mm, E= (1+0,5) mm and W= (81,5+0,5) mm, tighten the torque control rod clamp bolt 16...25 Nm (1.6...2.5 kgf·m);

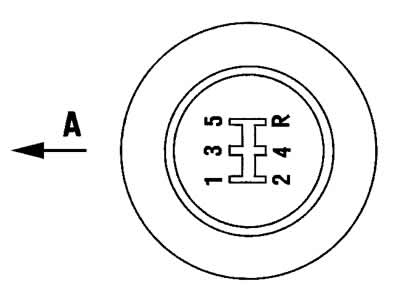

- when installing the gear lever handle, ensure its position relative to the direction of movement of the vehicle, as indicated in view A (pic. 3-27).

Pic. 3-27. Installing the gear selector knob:

A is the direction of the car.