The order of disassembly is as follows:

- release clamps 9 and 14 (see fig. 3-77), remove them from the rubber boot 6 and from the casing and slide the casing with the cover on the shaft to open access to the holder 11 of the hinge;

- using a drift and a hammer, knock clip 11 off the shaft;

Warning. In order to avoid jamming of the retaining ring 12, it is important to prevent the clip from being skewed by choosing the right force and direction of impact.

- slide the thrust ring 7, the protective cover 6 and the casing 5 off the shaft 4;

- slide the protective cover of the internal hinge on the shaft and, having removed the latch 2, remove the shaft 4 complete with the cage, separator and balls from the housing 1;

- using a drift and a hammer, knock the inner hinge cage off the shaft 4;

- after removing the thrust ring, slide the protective cover off the shaft;

- wash the internal cavities of the hinge housings and other parts.

The most complex and responsible operations are the disassembly and assembly of the outer hinge, the details of which are shown in Fig. 3-77. Good quality dismantling and assembly work is ensured by following the methods below.

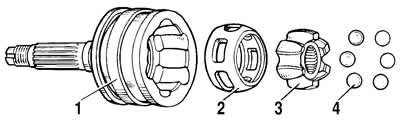

Pic. 3-77. Details of the front wheel drive outer joint:

1 - hinge body;

2 - separator;

3 - clip;

4 - ball.

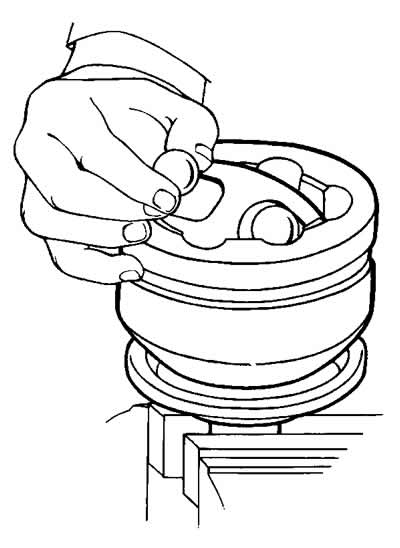

Mark with paint the relative position of the cage, separator and hinge housing. Secure the outer joint in a vise as shown in fig. 3-78. Tilt the cage and separator so that one ball comes out of the groove of the hinge body as completely as possible. Using a soft metal screwdriver, pry the ball out of the cage. Then turn all the parts so that the adjacent ball takes the same position, and remove it from the separator. Using the indicated methods, remove the remaining balls. The sequence of removing the balls from the separator can be different - through one ball.

Pic. 3-78. Removing the ball from the separator.

Slight tapping on the separator or cage with an object made of soft material is allowed. Excessive force when turning the separator is unacceptable, as it is possible to block the balls, which will make further disassembly difficult.

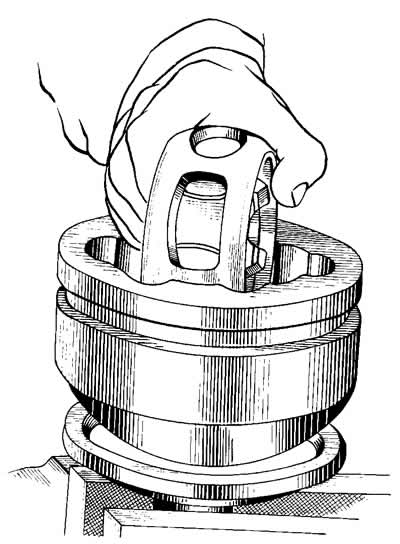

Install the cage with the cage so that the elongated holes of the cage are located against the protrusions of the hinge housing (see fig. 3-79) and remove the cage assembly.

Pic. 3-79. Removing the separator assembly with the cage from the hinge body.

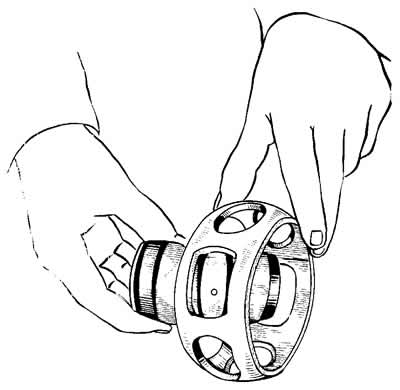

Remove the cage from the separator, for which one of the protrusions of the cage is placed in the elongated hole of the separator (see fig. 3-80) and then roll out the clip towards the straight edge of the hole. Rinse all parts and blow with compressed air.

Pic. 3-80. Removing the clip from the separator.

The assembly of the outer hinge is carried out in the reverse order of disassembly, taking into account the following:

- before assembly, lubricate all parts with SHRUS-4 grease;

- when installing the separator assembly with the cage into the hinge body, ensure that the marks made before disassembly match, place the cage with an annular groove (under the thrust ring) towards the shaft, and the separator - with a chamfer towards the bottom of the hinge housing;

- when installing the balls in the separator, tilt the cage approximately at an angle twice as large as the separator;

- fill the joint with SHRUS-4 grease in the amount of 60 cm3;

- before hitting shaft 4 (see fig. 3-76) to connect it with the inner race 11, it is necessary to install a new retaining ring 12 strictly in the center, and then sharply hit down the end of the shaft; the retaining ring will shrink and slip through the slotted hole of the clip;

- when pressing in the sealing ring of the hinge housing, use a mandrel.

After assembly, the cage may block when the shaft swings when the ball does not rotate. This is not a sign of poor build quality, as there will be no such blockage when the hinge rotates during operation.

Using the above techniques, completely disassemble the inner hinge. In this case, the clip must be removed towards the large diameter of the separator.

Assemble the inner hinge in reverse order. In this case, it is necessary to combine the marks applied before disassembly. The elongated conical part of the separator should be directed towards shaft 4. When assembling, fill the hinge with SHRUS-4 grease in the amount of 150 cm.

When installing the protective covers of the hinges, use a mandrel.

If there are no knocks and vibrations, protective covers are in good condition, then disassembly of the front wheel drive is not recommended.