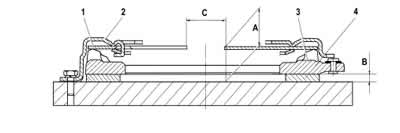

Checking the condition of the clutch pressure plate assembly. Fix pressure plate 3 (pic. 3-4) complete with pressure spring 1 and casing 2 on a fixture with an intermediate ring 4, thickness B= (8,3+0,01) mm. This tool replaces the flywheel with driven disc.

Pic. 3-4. Clutch control:

1 - pressure spring;

2 - clutch cover;

3 - pressure plate;

4 - intermediate ring;

A, B, C - dimensions.

Carry out the control by disengaging the clutch three times with a disengagement stroke of 8-9 mm, applying a load to the pressure spring petals 1 at a diameter of C=34 mm. Wherein:

- check that the shutdown progress (8,0+0,1) mm corresponds to a pressure plate travel of at least 1.4 mm;

- the difference in the displacement of the pressure plate 3 is not more than 0.25 mm;

- dimension A must be within (35,7+1) mm;

- load on the petals of pressure spring 1 on diameter C during stroke (8,0+0,1) mm should be no more than 1330 N, peak shutdown load no more than 1720 N.

Measure the depth of the annular wear of the pressure spring petals at the point of contact with the clutch release bearing, if the wear exceeds 0.8 mm, replace the clutch cover assembly with the pressure plate.