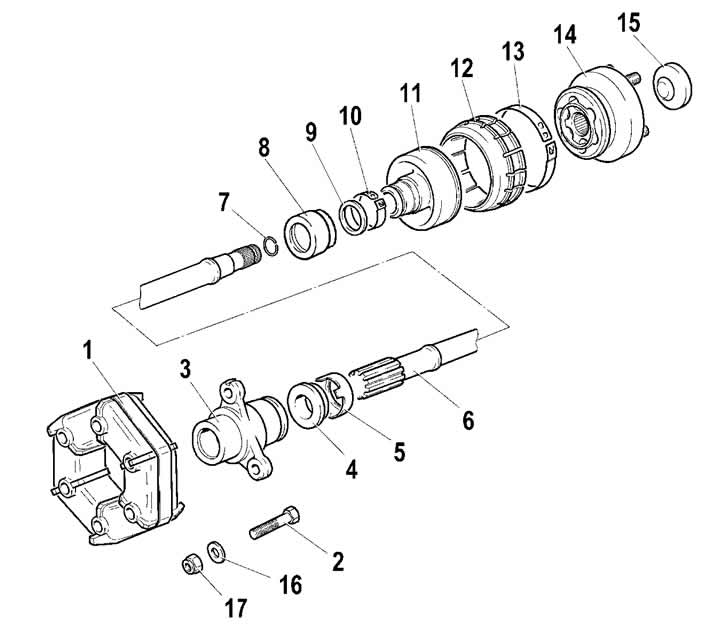

Pic. 3-43. Details of the intermediate cardan shaft:

1 - elastic coupling with clamp A.70025;

2 - bolt;

3 - sliding flange;

4 - flange gland;

5 - stuffing box holder;

6 - intermediate shaft;

7 - retaining ring;

8 - valve casing;

9 - hinge cover valve;

10 - collar;

11 - hinge cover;

12 - hinge cover casing;

13 - collar;

14 - hinge of equal angular velocities;

15 - plug;

16 - balancing washer;

17 - self-locking nut.

If the hinge cover is damaged, when it is necessary to check the condition of the hinge parts and the quality of lubrication, noting the position of the hinge relative to shaft 6, remove and disassemble the hinge using the techniques described in subsection «Front wheel drive». When assembling the constant velocity joint, put grease in «Esma» in the amount of 20 cm2.

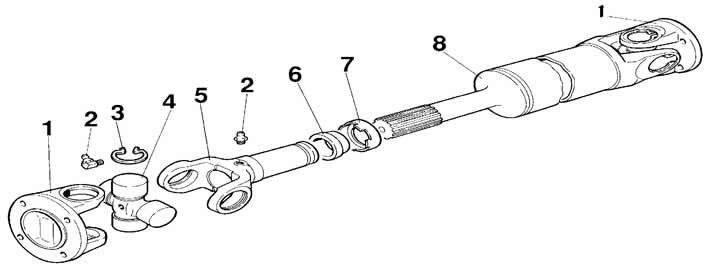

Front and rear shafts. Apply marks (paint or punch), which determine the relative position of the mating parts in order to connect them during assembly in the same position to maintain the balance of the shafts.

Install in vise with aluminum lining front (rear) cardan shaft. Remove retaining rings 3 (pic. 3-44), using round nose pliers.

Pic. 3-44. Front driveshaft details:

1 - flange-fork of the cardan joint;

2 - grease fitting (not available in the variant);

3 - retaining ring;

4 - cross assembly;

5 - sliding fork;

6 - stuffing box;

7 – stuffing box holder;

8 - cardan shaft.

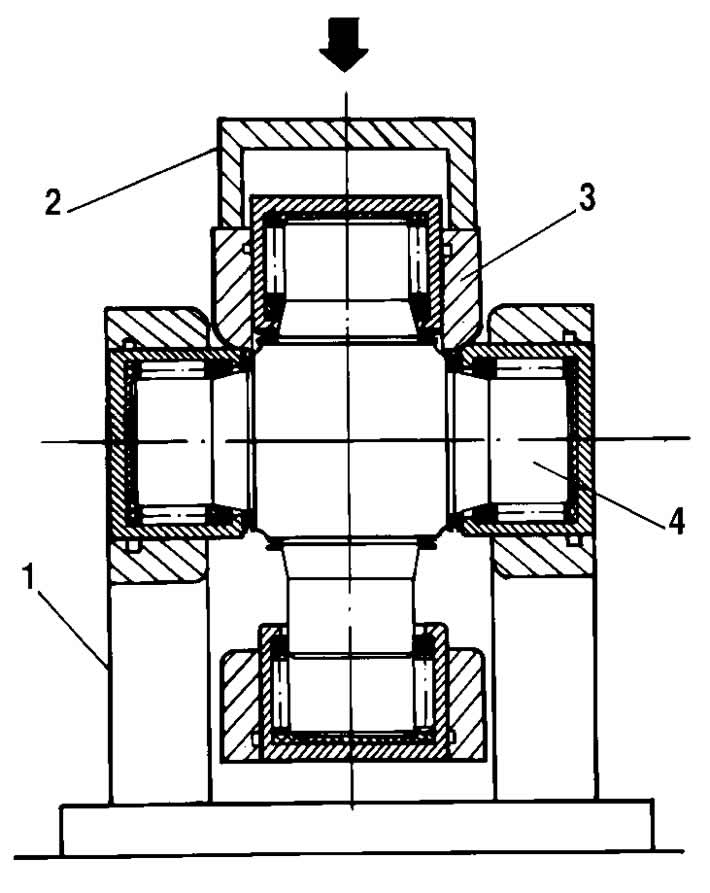

Press the bearing housings out of the hinge forks, for which:

- install the cardan shaft of one of the forks of the cardan joint on the support 1 (pic. 3-45) press. Move the other fork through the special bushing 2 using the press rod (pos. 3) hinge down to the stop in the crosspiece;

- turning the hinge fork by 1800, repeat the indicated operations, i.e. move the other end of the fork down until it stops against the cross. When performing these operations, the opposite bearing of the cross will partially come out of the fork hole and it will be possible to install the sleeve 1 into the resulting gap between the fork and the cross (pic. 3-46) with a side cutout for further complete disassembly of the bearing;

- having installed the sleeve 1 on the spike of the cross, move the hinge fork down until the bearing is pressed out;

- using the indicated techniques, press out the other bearings of the spider.

Pic. 3-45. Disassembly of the universal joint:

1 - press support;

2 - bushing;

3 - hinge fork;

4 - cross.

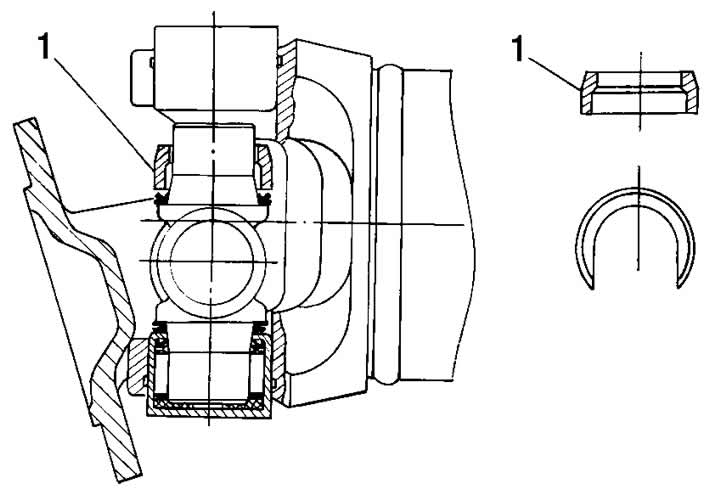

Pic. 3-46. Installing the sleeve for disassembling the universal joint:

1 - bushing.

Note. On parts of cars, front and rear cardan shafts manufactured by the company are installed «TIRSAN KARDAN A.S.» (Türkiye), which are not subject to disassembly and repair due to delivery to spare parts only as a complete unit.

Note. Front and rear cardan shafts with constant velocity joints are installed on parts of cars. Dismantle and assemble the hinges using the techniques described in the chapter «Front wheel drive».