On the teeth of the gears of the oil pump drive and the ignition distributor, chipping, chips, nicks, hardening are not allowed. With such defects, replace the gears and roller with new ones.

Oil pump drive shaft bushings. Check the inner diameter of the bushings, their pressing into the sockets, as well as the coincidence of the lubrication hole in the front bushing with the channel in the cylinder block (turning the sleeve). The inner surface must be smooth and free of burrs.

By measuring the diameters of the roller and bushings, determine the gaps between the bushings and the bearing surfaces of the roller. If the gap exceeds 0.15mm (wear limit), as well as in case of damage to the surfaces of the bushings or weakening of their pressing, replace the bushings with new ones.

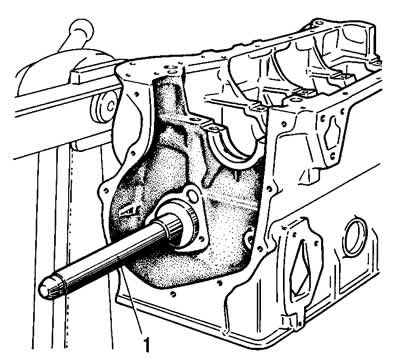

Pic. 2-73. Removal and installation of bushings of the oil pump drive shaft and ignition distributor:

1 - mandrel A.60333/1/2.

When replacing, use tool A.60333/1/2 both for removal and installation (pic. 273), by observing the following:

- the bushings must be pressed into the sockets, while the oil hole in the front bushing must be against the channel in the cylinder block;

- after pressing in, the bushings must be finished and finished to the inside diameter (dimensions are given in fig. 2-68). To ensure complete alignment of the roller bushings, a reamer A.90353 is used to finish them, which simultaneously processes both bushings.

Oil pump drive gear bushing. Check bushing tightness. The inner surface must be smooth and without scoring, otherwise replace the bushing.

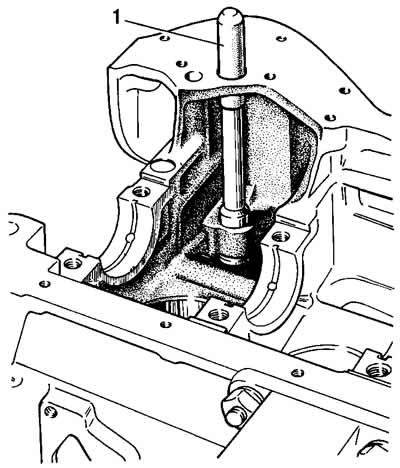

Use tool A.60326/R to press out and press in the bushing (pic. 2-74).

Pic. 2-74. Pressing out the bushing of the oil pump drive gear and the ignition distributor:

1 - mandrel A.60326/R.

After pressing the bushing, process it with a reamer up to 16.016-16.037 mm.