Remove the right and left rear seats.

Remove facings of 3 thresholds back, rugs of a floor of a luggage carrier forward and back.

Remove an upholstery of 4 racks of a back right and an upholstery of 5 arches and sidewalls right.

Remove cover 2 of the fuel tank.

Disconnect the rear wiring harness connector from the fuel pump.

Start the engine and let it run at idle to relieve pressure in the fuel system until it comes to a complete stop.

Disconnect the fuel line fittings from the fuel pump 7.

Loosen the clamps and disconnect hoses 10, 11, 13 from the fuel tank.

Remove the two bolts and two nuts securing the fuel tank and remove the fuel tank.

Install the fuel tank in reverse order.

Cleaning and control. Remove the electric fuel pump 7. To remove dirt and deposits, flush the tank with gasoline. Then rinse and steam the tank from gasoline residues with a jet of hot water.

Carefully inspect the fuel tank along the joint line, welding should be uniform and continuous, without cracks and unwelded areas.

Check the tank for tightness by supplying air under pressure of 0.02-0.03 MPa (0.15-0.25 kgf/cm2) in a water bath for 50 s, if necessary, solder the leak with soft solder.

Warning. You can only solder a well-washed fuel tank that does not contain gasoline vapors, which can ignite when soldered.

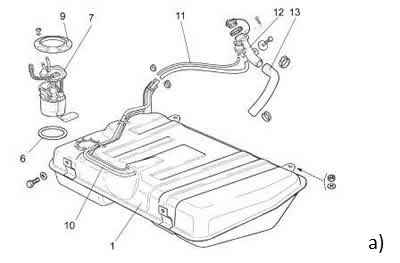

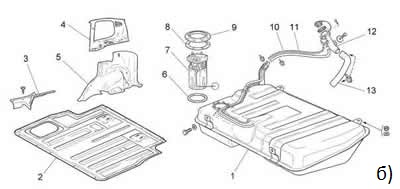

Pic. 2-76. Removing the fuel tank:

A) for ECM with MP7.0 controller;

b) for ECM with M7.9.7 controller;

1 - fuel tank;

2 - fuel tank cap;

3 - rear sill lining;

4 - upholstery of the rear rack, right;

5 - upholstery of the arch and sidewall, right;

6 - gasket;

7 - electric fuel pump;

8 - distance ring;

9 - clamping ring;

10 - air pipes hose;

11 - fuel tank ventilation hose;

12 - filling pipe;

13 - inlet pipe hose.