Device Features

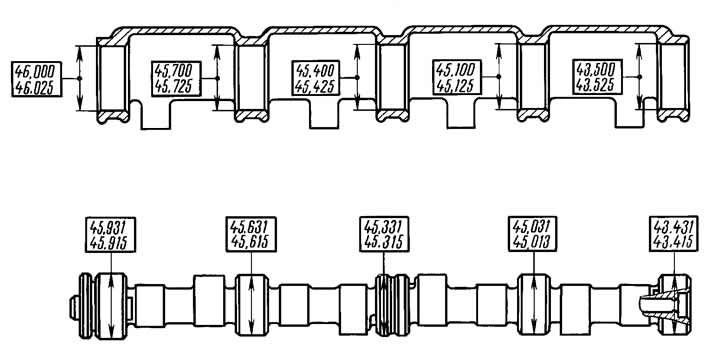

The camshaft is cast iron, rests on five journals and rotates in an aluminum bearing housing mounted on the cylinder head. The main dimensions of the camshaft and bearing housing are given in fig. 2-56. Cam surfaces are whitened for increased wear resistance. From axial movements, the camshaft is held by a thrust flange placed in the groove of the front bearing journal of the shaft.

Pic. 2-56. The main dimensions of the camshaft and bearing housing.

The camshaft is driven from the drive sprocket 8 (see fig. 2-12) crankshaft with a single-row roller chain 1. The same chain drives the sprocket 7 of the oil pump drive shaft. The chain drive has a hydraulic tensioner 4 with a shoe 2 and a chain damper 6.

The hydraulic tensioner provides chain tension immediately after its installation.

Chain replacement

To remove the chain, brake the car with a parking brake, remove the battery.

Following the recommendations in section «Removal and installation of the engine», drain the coolant, remove the radiator assembly with fans, air filter, intake pipe hose.

Disconnect the ignition harness connectors from the phase sensor and from the crankshaft position sensor. Remove the phase sensor from the cylinder head.

Remove the cylinder head cover and turn the crankshaft until the mark on the camshaft sprocket aligns with the mark on the bearing housing (see fig. 2-26), and the marks on the crankshaft damper with a long mark on the camshaft drive cover.

Loosen the accessory and compressor drive belts, remove the belts.

Loosen the camshaft sprocket bolt.

Disconnect the oil supply pipe from the hydraulic tensioner, unscrew the two nuts and remove the hydraulic tensioner.

Remove the camshaft sprocket.

Engage fourth gear in the gearbox, unscrew the nut and remove the damper from the crankshaft.

Unscrew the nuts securing the cover to the cylinder block and the bolts securing the oil sump to the cover, remove the camshaft drive cover with gasket.

Remove the chain tensioner shoe mounting bolt, the chain damper mounting bolts, remove the shoe, damper and camshaft drive chain.

Install the chain in the reverse order of removal, following the recommendations set out in subsection «Engine assembly». Lubricate the chain with engine oil before installation. Install new gaskets under the camshaft drive cover and cylinder head cover.

Checking the technical condition

Camshaft. On the bearing journals of the camshaft, scuffing, nicks, scratches, aluminum enveloping from bearing housings are not allowed. On the working surfaces of the cams, wear of more than 0.5 mm is not allowed, as well as scuffing and wear of the cams in the form of a cut.

Install the camshaft with the outer journals on two prisms located on the calibration plate, and measure the radial runout of the middle journals with an indicator, which should be no more than 0.03 mm. If the runout exceeds the specified value, then straighten the shaft on a straightening press.

Camshaft bearing housing. Rinse and clean the bearing housing and oil passages.

Check the diameter of the holes in the supports. If the clearance between the camshaft journals and bearings exceeds 0.2 mm (wear limit), replace the bearing housing.

Internal bearing surfaces must be smooth, free of burrs; if there is damage, replace the bearing housing. Check for cracks on the case. If there are cracks, replace the camshaft bearing housing.

Hydraulic tensioner. When repairing, the tensioner housing and the plunger make up a pair in which the replacement of one part with another after selection is not allowed, therefore the tensioner cannot be repaired and is replaced with a new one.

Check for excessive wear on the shoe and damper; replace if necessary.

Camshaft drive chain. Rinse the chain in kerosene, and then check the condition of its links. On rollers and cheeks, chips, cracks and other damage are not allowed.

When the engine is running, the chain parts wear out, so the chain is stretched. It is considered operational as long as the tensioner provides its tension, i.e. if the chain elongation does not exceed 4 mm.

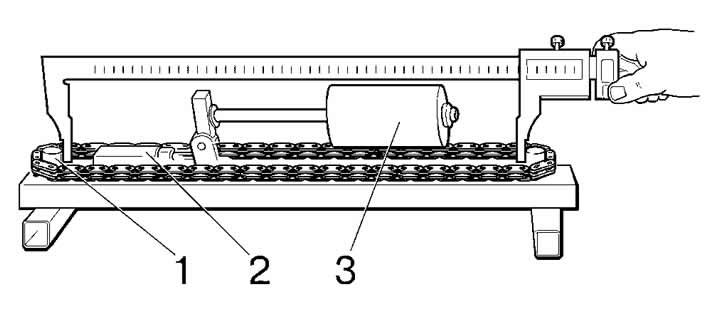

Determine the length of the chain using tool 67.7824-9521, the appearance of which is shown in Figure 2-57.

Pic. 2-57. Wear Check Tool 67.7824-9521 (hoods) chains:

1 - roller;

2 - adjusting nut;

3 - counterweight.

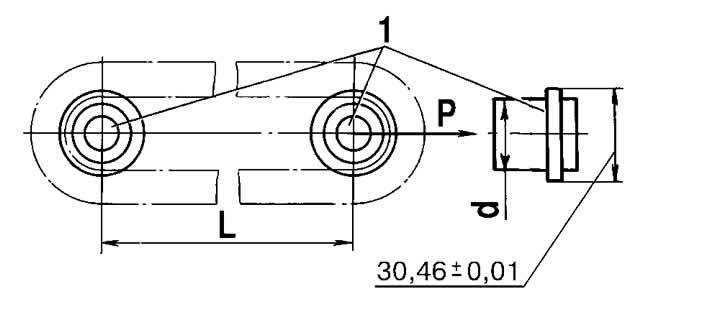

Pic. 2-58. Wear Check Diagram (hoods) chains:

1- rollers.

See Figure 2-58 for a circuit for measuring chain length.

Device 67.7824-9521 has two stepped measuring rollers 1, on which the chain is installed when measuring its length. One of the rollers is fixed in the fixture body, and the second can move under the action of the measuring force P. With the help of counterweight 3 (see fig. 2-57) the chain is stretched with a force of 294 N (30 kg s) or 147 N (15 kg s). The adjusting nut 2 ensures that the axis of the counterweight is parallel to the base of the device.

The chain length is determined by the center distance L of the measuring rollers 1 (see fig. 2-58). The new chain has a length L of 495.4-495.8 mm. If the chain is 499.8 mm long due to wear, it should be replaced.

Measure the chain length in the following sequence:

- stretch the chain with a force of 294 N (30 kgf), placing a counterweight 3 (see fig. 2-57) to the extreme right position, then reduce the force to 147 N (15 kg s), by moving the counterweight to the extreme left position;

- repeat both operations again;

- measuring the internal distance between the measuring rollers 1 with a caliper and adding the diameter of the roller d to it, get the length of the chain L (distance between the axes of the measuring rollers).

Lubricate the chain with engine oil before installing on the engine.