Record working diagrams according to the instructions attached to the stand, after performing at least 5 working cycles, at the temperature of the working fluid of the shock absorber (20+5) °C, flywheel speed 60 min and stroke length 100 mm for the front shock absorber.

Chart Curve (pic. 4-16) should be smooth, and at the transition points (from recoil to compression stroke) - without sections parallel to the zero line.

Evaluation of results according to the diagram. The resistance of the recoil and compression stroke is determined by the largest ordinates of the corresponding diagrams.

The highest point of the recoil travel curve at a scale of 1 mm = 47 N (4.8 kgf) should be located at a distance A from the zero line, equal to: 33.3-40.7 mm for front shock absorbers, 23.5-30.5 mm for rear shock absorbers.

The highest point of the compression stroke curve at the same scale should be at a distance B from the zero line, equal to 3.5-6.5 mm - for front and rear shock absorbers.

The control values of the ordinates on the diagrams of the front and rear shock absorbers are set for cold shock absorbers at the temperature of the shock absorber (20+5) °C.

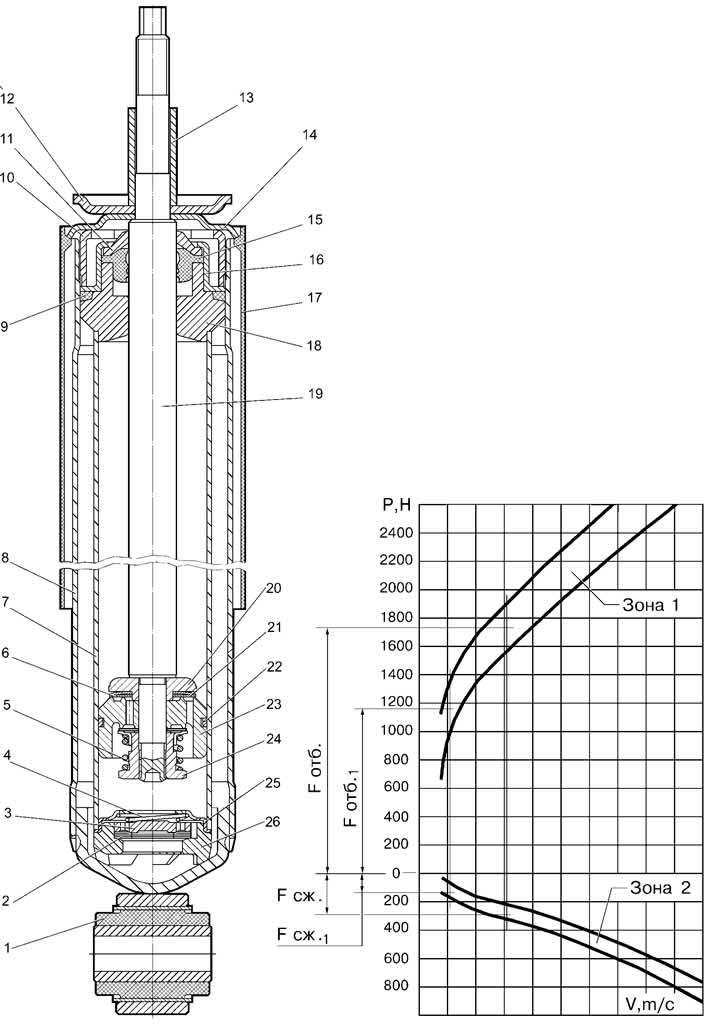

Shock absorber speed characteristic (see fig. 4-15) at damper fluid temperature (20±5) °C and stroke (100±1) mm must fit into zone 1 during rebound and into zone 2 during compression. The control of forces Freb, Freb1, Fcool, Fszh1 is carried out according to TU 37.370.016-2001.

Pic. 4-16. Shock absorber working diagram:

I - effort during recoil;

II - effort during compression.