Loosen the nut and remove the pinch bolt securing the lower end of the intermediate shaft 1 (see fig. 5-2) to the steering screw shaft 11 (see fig. 5-1).

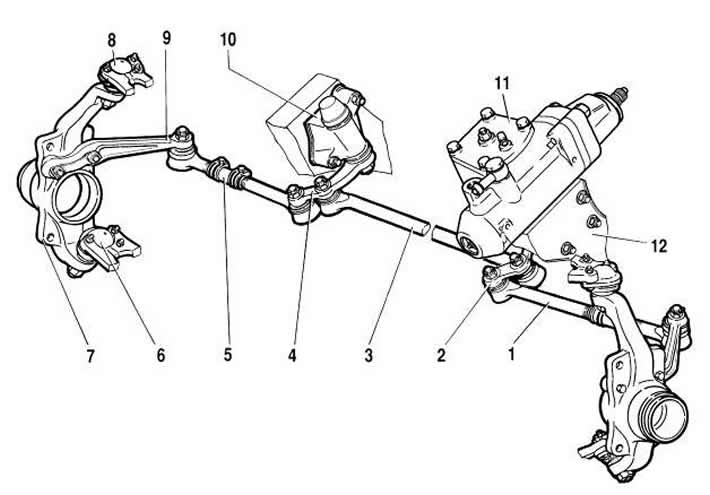

Pic. 5-1. Steering gear assembly with drive:

1 - lateral thrust;

2 - bipod;

3 - medium thrust;

4 - pendulum lever;

5 - adjusting clutch;

6 - lower ball joint of the suspension;

7 - right rotary fist;

8 - upper ball joint of the suspension;

9 - lever of the right steering knuckle;

10 - pendulum arm bracket;

11 - steering mechanism;

12 - body spar.

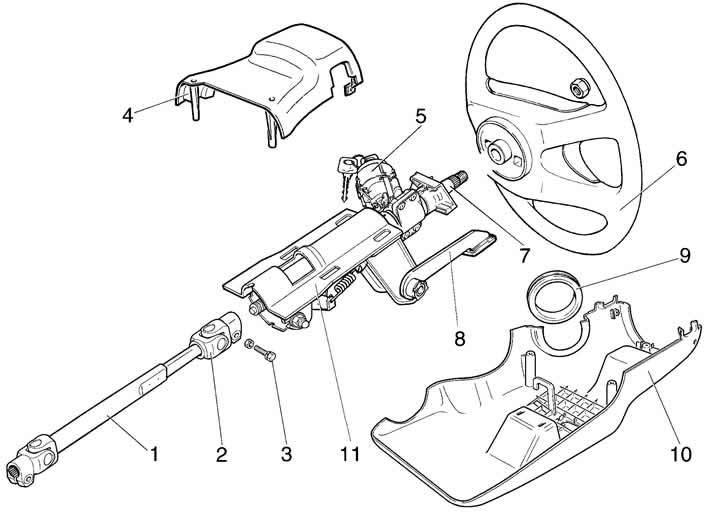

Pic. 5-2. Steering column elements:

1 - intermediate shaft with a hinge;

2 - cardan joint;

3 - coupling bolt;

4 - upper casing;

5 - ignition switch;

6 - steering wheel;

7 - steering shaft;

8 - steering column tilt adjustment lever;

9 - sealing ring;

10 - lower casing;

11 - steering column bracket.

Unpin and unscrew the nuts of the ball studs on the bipod 2, press the ball studs out of the holes of the bipod using puller A.47035.

Remove oil from tank 9 (see fig. 5-3) power steering.

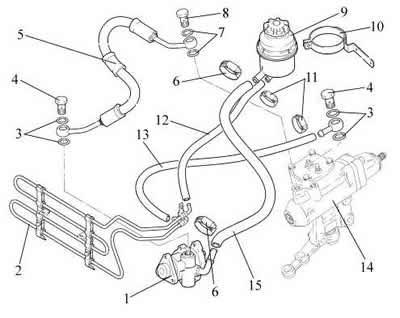

Pic. 5-3. Power steering system:

1 - power steering oil pump;

2 - heat exchanger;

3 - gasket 2108-3512115;

4 - bolt-fitting M16x1.5 2123-3408144;

5 - high pressure hose;

6 - screw clamp 2108-1300080-60;

7 - gasket 1/02824/60;

8 - bolt-fitting M14x1.5 2123-3408070;

9 - oil tank;

10 - oil tank mounting bracket;

11 - screw clamp 2108-130008050;

12 - low pressure hose;

13 - low pressure drain hose;

14 - steering mechanism;

15 - supply hose.

Unscrew the bolt 8 fastening the hose 5 to the steering mechanism and the clamp 11 of the hose 13 (see fig. 5-3). Use process plugs in hose ends to prevent fluid loss from the power steering system.

Turn away nuts of bolts of fastening of the steering mechanism to a side member 12 (see fig. 5-1) body and remove the steering gear.

Install in the reverse order of removal, doing the following:

- set the bipod of the steering mechanism to the middle position;

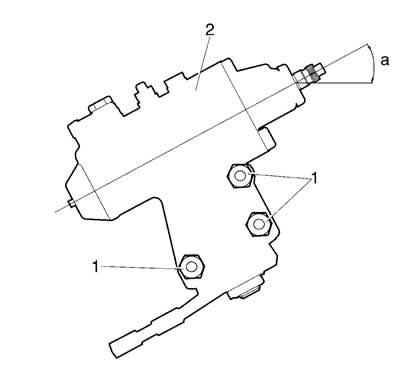

- before tightening the bolt nuts 1 (pic. 5-4), orient the steering mechanism with a special device so that the angle a = 28°;

- check and, if necessary, adjust the angles of the front wheels.

Filling the hydraulic system with oil and bleeding the hydraulic system.

- turn the wheels to the left as far as they will go and fill the hydraulic booster hydraulic system with oil;

- bleed the system by turning the wheels from lock to lock 4...5 times while monitoring the presence of oil in the tank;

- in the extreme positions of the wheels, remove air from the steering mechanism by unscrewing the bleeder valve;

- check the oil level in the tank and briefly start the engine, check the oil in the tank. If necessary, add oil to the tank;

- start the engine and turn the wheels from lock to lock 2...3 times;

- turn off the engine and again bleed the air from the steering mechanism;

- check the oil level in the reservoir and, if necessary, top up the oil level. The oil level should be between the marks on the dipstick on the tank cap.

Warning. Before installing the hoses, check for cracks, ruptures and fogging of the hoses, if necessary, replace them with new ones. Replace the sealing copper gaskets of the high-pressure hose ends with new ones. In order to avoid failure of the pump, it is strictly forbidden to start the engine if there is no oil in the hydraulic system or if the steering hydraulic system is not pumped.

Pic. 5-4. Installation of the steering mechanism on the car:

1 - bolts of fastening of the steering mechanism;

2 - steering mechanism;

a is the control angle.