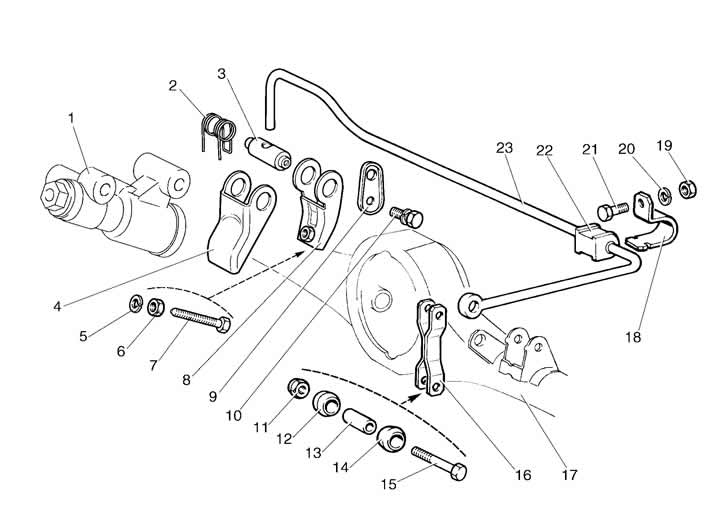

Pic. 6-24. Pressure Regulator Actuator Details:

1 - pressure regulator;

2 - lever spring;

3 - axis of the regulator drive lever;

4 - lever of the pressure regulator drive piston;

5 - spring washer;

6 - nut;

7 - adjusting bolt;

8 - pressure regulator drive lever;

9 - lever base plate;

10 - bolt with spring washer;

11 - bolt nut 15;

12, 14 - plastic sleeve;

13 - spacer sleeve;

15 - a bolt of fastening of draft;

16 - rod connecting the pressure regulator drive lever with the rear axle bracket;

17 - rear axle beam;

18 - holder of the support sleeve;

19 - nut;

20 - spring washer;

21 - a bolt of fastening of a clip to an arm;

22 - support bushing of the drive lever;

23 - pressure regulator drive lever.

Disconnect the muffler suspension parts from the body and take the pipeline with the mufflers to the side.

Having unscrewed the bolts securing the regulator to the bracket and the bracket to the body, remove the regulator bracket, and then, lowering the regulator down, disconnect the pipelines from it.

Remove the regulator and disconnect the drive lever from it. Plug the inlets and outlets of the pressure regulator and piping.

Install the pressure regulator in the reverse order of removal. Before installing traction 5 (pic. 6-5) check the correct adjustment of the regulator drive and, if necessary, carry out it, as described in the section «Pressure Regulator Actuator Adjustment».

Bleed the brakes to remove air from the rear brake actuator.

The pressure regulator regulates the pressure in the hydraulic drive of the rear wheel brakes depending on the load on the rear axle of the vehicle. It is included in both circuits of the brake system and through it the brake fluid flows to both rear brake mechanisms.

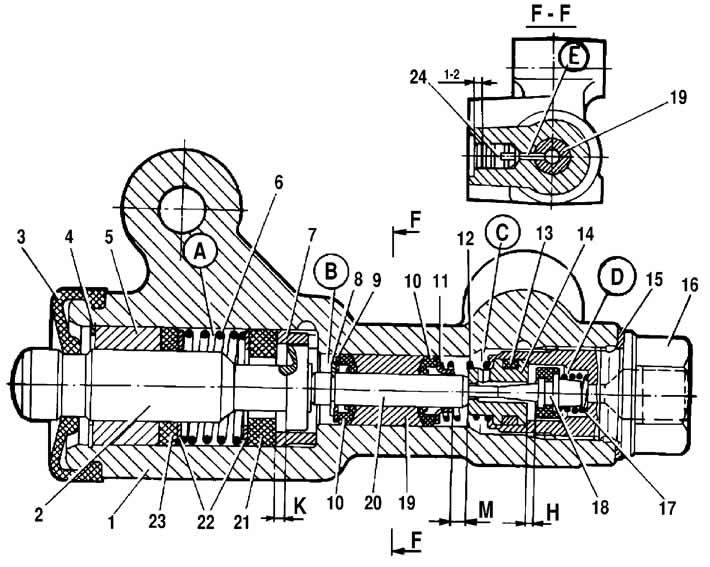

Pic. 6-25. Rear brake pressure regulator in non-working position:

1 - pressure regulator housing;

2 - piston;

3 - protective cap;

4, 8 - retaining rings;

5 - piston sleeve;

6 - piston spring;

7 - housing sleeve;

9, 22 - support washers;

10 - pusher sealing rings;

11 - support plate;

12 - pusher bushing spring;

13 - valve seat sealing ring;

14 - valve seat;

15 - sealing gasket;

16 - cork;

17 - valve spring;

18 - valve;

19 - pusher bushing;

20 - pusher;

21 - piston head seal;

23 - piston rod seal;

24 - plug;

A, D - cameras connected to the main cylinder;

B, C - chambers connected to the wheel cylinders of the rear brakes;

K, M, H - gaps.

The regulator has four chambers: A and D (pic. 6-25) connected to the master cylinder, B - to the left, and C - to the right wheel cylinders of the rear brakes.

In the initial position of the brake pedal, piston 2 (see fig. 6-25) pressed by lever 6 (see fig. 6-5) through spring 5 to pusher 20 (see fig. 6-25), which under this force is pressed against the seat 14 of the valve 18. In this case, the valve 18 is pressed from the seat and a gap H is formed, as well as a gap K between the piston head and the seal 21. Through these gaps, the chambers A and D communicate with the chambers B and C.

When you press the brake pedal, the fluid through the gaps K and H and chambers B and C enters the wheel cylinders of the brake mechanisms. With an increase in fluid pressure, the force on the piston increases, tending to push it out of the housing. When the force from the fluid pressure exceeds the force from the elastic lever, the piston begins to move out of the body, and after it, the pusher 20 moves under the action of the springs 12 and 17 together with the sleeve 19 and rings 10. In this case, the gap M increases, and the gaps H and K decrease. When the gap H is completely selected and the valve 18 isolates chamber D from chamber C, the pusher 20, together with the parts located on it, stops moving after the piston. Now the pressure in chamber C will change depending on the pressure in chamber B. With a further increase in the effort on the brake pedal, the pressure in chambers D, B and A increases, piston 2 continues to move out of the housing, and sleeve 19, together with o-rings 10 and plate 11 under increasing pressure in chamber B, it shifts towards plug 16. At the same time, gap M begins to decrease. By reducing the volume of chamber C, the pressure in it, and hence in the brake drive, increases and will practically be equal to the pressure in chamber B. When gap K becomes zero, the pressure in chamber B, and hence in chamber C, will increase to a lesser extent. degree than the pressure in chamber A due to the throttling of fluid between the piston head and seal 21. The relationship between the pressure in chambers B and A is determined by the ratio of the difference in the areas of the head and piston rod to the area of the head.

With an increase in the load of the car, the elastic lever 6 (see fig. 6-5) is loaded more and the force from the lever 2 on the piston increases, that is, the moment of contact between the piston head and the seal 21 (see fig. 6-25) achieved with a higher pressure in the master brake cylinder. Thus, the effectiveness of the rear brakes increases with increasing load.

If the brake circuit fails «left front - right rear brakes», sealing rings 10, bushing 19 under the pressure of the fluid in chamber B will move towards the plug 16 until the plate 11 stops in the seat 14. The pressure in the rear brake will be regulated by the part of the regulator, which includes piston 2 with seal 21 and bushing 7. The operation of this part of the regulator, in case of failure of the named circuit, is similar to operation with a working system. The nature of the change in pressure at the outlet of the regulator is the same as with a working system.

If the brake circuit fails «right front - left rear brakes» brake fluid pressure pusher 20 with sleeve 19, o-rings 10 is displaced towards the piston, pushing it out of the housing. The gap M increases and the gap H decreases. When the valve 18 touches the seat 14, the pressure increase in the chamber C stops, that is, the regulator in this case works as a pressure limiter. However, the amount of pressure achieved is sufficient for reliable operation of the rear brake.

A hole is made in the body 1, closed with a plug 24. The leakage of liquid from under the plug when it is squeezed out indicates the leakage of the rings 10.