Remove protective caps 2 (pic. 6-20), then press the pistons 4 complete with the parts of the device for automatically adjusting the gap between the brake pads and the drum from the cylinder body 3.

Pic. 6-20. Wheel Cylinder:

1 - pad stop;

2 - protective cap;

3 - cylinder body;

4 - piston;

5 - sealant;

6 - support cup;

7 - spring;

8 - crackers;

9 - thrust ring;

10 - stop screw;

11 - fitting;

A - a slot on the thrust ring.

Install the piston assembly with the automatic device on the special tool so that the protrusions of the tool cover the head of the stop screw 3 (pic. 6-21). Using a screwdriver, turning the piston 9, unscrew the stop screw 3 from the piston. Remove the seal 8 with the support cup 7 and crackers 5 from the screw. Separate the thrust ring 4 and the thrust screw 3.

Pic. 6-21. Wheel Cylinder Details:

1 - piston assembly;

2 - cylinder body;

3 - stop screw;

4 - thrust ring;

5 - crackers;

6 - spring;

7 - support cup;

8 - sealant;

9 - piston;

10 - protective cap.

Assemble the automatic device and the wheel cylinder itself in the reverse order, taking into account the following:

- tighten the thrust screws of the pistons with a torque of 4... 7 Nm (0.4...0.7 kgf·m);

- slot A (see fig. 6-18) on the thrust rings must be directed vertically upwards; deviation from the vertical is allowed no more than 30°. This arrangement of the slot provides a more complete removal of air from the brake mechanism when it is pumped;

- to pre-compress the thrust rings, press the pistons into the cylinder body using a special tool in the form of a cylinder with a conical inner hole;

- the force of pressing the piston into the cylinder must be at least 350 N (35 kgf); with force less than 350 N (35 kgf) replace the thrust ring;

- when pressing the piston into the cylinder, it is necessary to maintain the dimensions 4.5 - 4.8 mm and 67 mm (maximum) (see fig. 6-18) for free fit of the brake drum;

- Before installing parts in the cylinder body, lubricate them liberally with brake fluid.

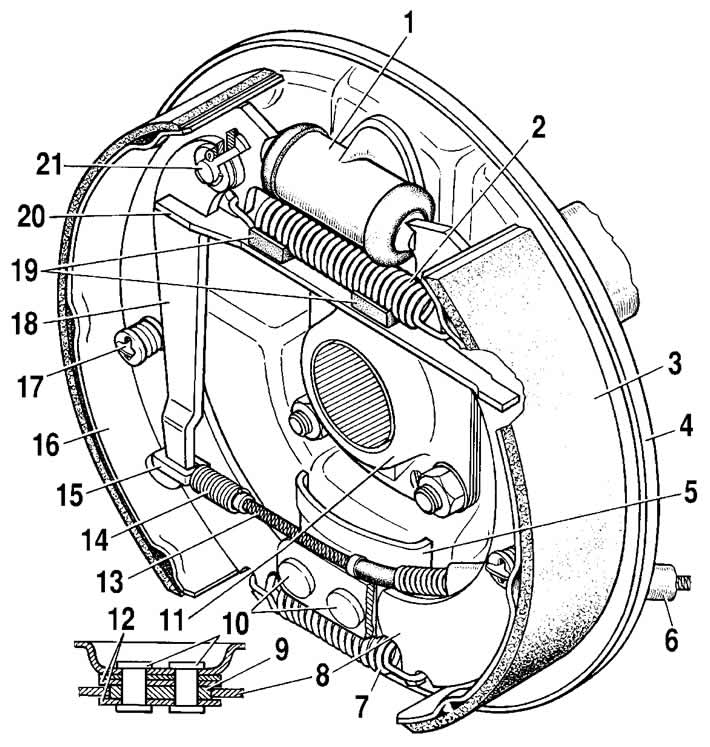

Pic. 6-18. Rear wheel brake:

1 - wheel cylinder;

2 - the upper coupling spring of the shoes;

3 - overlay pads;

4 - brake shield;

5 - inner plate;

6 - shell of the rear cable;

7 - lower coupling spring of the shoes;

8 - front brake shoe;

9 - pad base plate;

10 - rivets;

11 - oil deflector;

12 - guide plates of pads;

13 - rear parking brake cable;

14 - rear cable spring;

15 - tip of the rear cable;

16 - rear brake shoe;

17 - support column pads;

18 - lever for manual drive of the pads;

19 - rubber pads;

20 - spacer bar for pads;

21 - finger of the lever of the manual drive of the pads.

After assembly, check the movement of each piston in the cylinder body. They should move easily within 1.25-1.65 mm. Replace protective caps 2 last.