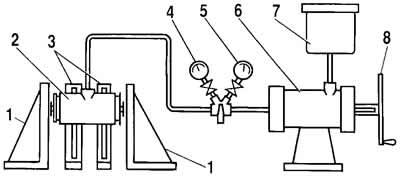

Pic. 6-23. Scheme for checking the wheel cylinders of the rear brakes:

1 - piston stops;

2 - tested cylinder;

3 - cylinder bracket;

4 - low pressure gauge;

5 - high pressure gauge;

6 - cylinder for creating pressure;

7 - vessel;

8 - flywheel.

Adjust stops 1 so that the pistons of the wheel cylinder rest against them, check for fluid leakage. Connect a low pressure manometer 4. Slowly rotating the flywheel 8, set the pressure gauge 4 fluid pressure 0.05 MPa (0.5 kgf/cm).

Ensure that the set pressure is maintained for 5 minutes. Repeat a similar test at a fluid pressure of 0.1-0.2-0.3 -0.4-0.5 MPa (1-2-3-4-5 kgf/cm).

Reduce pressure and connect high pressure manometer 5. Ensure that the pressure is maintained for 5 min, repeat the test at a liquid pressure of 5-10-15 MPa (50-100-150 kgf/cm2).

No reduction in pressure due to leakage of liquid through sealing elements, pipe connections, bleed fittings or through the pores of the casting is allowed.

A slight decrease in pressure is allowed, not more than 0.5 MPa (5 kgf/cm2) within 5 minutes, especially at higher pressures, due to shrinkage of the seals.