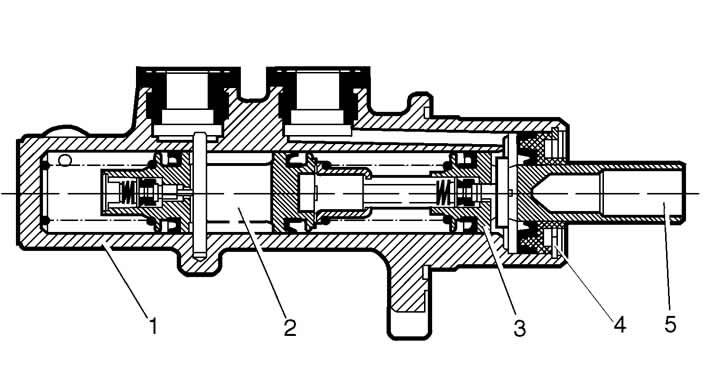

Pic. 6-9. Master cylinder:

1 - cylinder body;

2, 3 - pistons for driving the brake circuits;

4 - spacer washer;

5 - pusher.

Removal and installation. Disconnect the pipelines from the master cylinder and the block with wires from the terminals of the brake fluid emergency level sensor. Close the openings at the pipelines and at the master cylinder to prevent leakage of fluid from the system and the entry of dust, dirt or foreign matter into them.

Remove the cylinder assembly with the tank by unscrewing the nuts securing it to the vacuum booster. Remove the emergency brake fluid level sensor and drain the brake fluid from the reservoir and cylinder. It is not recommended to remove the reservoir from the master cylinder unless it is necessary.

Install the master cylinder in the reverse order of removal. After installing the cylinder, bleed the hydraulic drive system to remove air from it.

Disassembly and assembly. The master cylinder is non-separable and cannot be repaired. When it fails, it needs to be replaced.

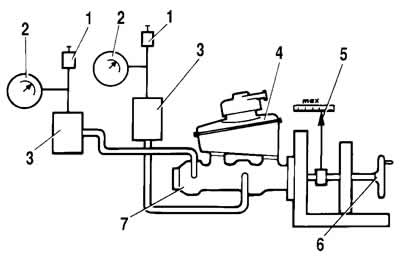

Master cylinder leak test. Install the main cylinder on the stand and connect it to the elements of the stand, as shown in fig. 6-10.

Pic. 6-10. Main cylinder leak test diagram:

1 - valve for pumping the stand;

2 - manometer;

3 - absorbing cylinder;

4 - tank of the main cylinder;

5 - pusher offset indicator;

6 - flywheel;

7 - master cylinder.

Open valves 1 to bleed the stand and, moving the master cylinder pistons several times to their full stroke, bleed the system. Then close the valves 1. By rotating the flywheel 5, slowly move the master cylinder pistons until the pressure controlled by the pressure gauges 2 reaches 12.5 MPa (125 kgf/cm2). In this position, block the pusher of the master cylinder. The specified pressure must remain constant for at least 5 s.

In case of fluid leakage or reduction of the set pressure within 5 s, replace the cylinder piston seals.