Withdrawal

Open the hood and disconnect the terminal "minus" from the battery.

Pump out the refrigerant from the air conditioning system, in accordance with the instructions for the service equipment.

Remove the noise shield, protective plate and engine mudguard.

Disconnect the harness connector from the windshield washer motor.

Remove the washer reservoir and take it to the side.

Loosen bolts 1 by 3-4 turns (pic. 8-70) fastening the tension roller bracket, loosen the tension of the compressor drive belt by turning the bolt 3 and remove the belt 4 from the compressor pulley.

Fig.8-70. Compressor drive belt tensioner:

1 - bolts for fastening the tension roller bracket;

2 - tension roller;

3 - bolt of the tension mechanism;

4 - compressor drive belt.

Disconnect the ignition harness connector from the compressor connector.

Remove bolt 3 (pic. 8-71), remove flange 4 of the compressor and disconnect lines 2 and 5 from the compressor.

Pic. 8-71. Fastening pipelines on the compressor:

1 - compressor;

2 - low pressure pipeline;

3 - compressor flange mounting bolt;

4 - compressor flange;

5 - injection pipeline.

Attention: install technological plugs on the hoses to prevent leakage of compressor oil.

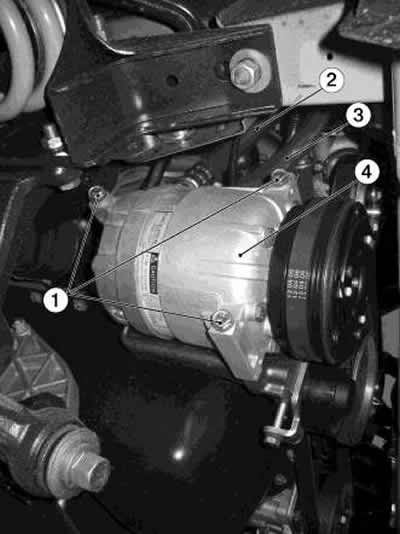

Remove three screws 1 (pic. 8-72) fastening the compressor to the bracket and remove the compressor 4.

Pic. 8-72. Removing the compressor:

1 - compressor mounting bolts;

2 - low pressure pipeline;

3 - injection pipeline;

4 - compressor.

Installation. Mount the compressor on the engine bracket and secure with three bolts 1 (fig.8-72): bolt tightening torque - 20...24 Nm (2.0...2.4 kgf·m).

Remove the technological plugs from the pipelines, install new sealing rings lubricated with compressor oil.

Install pipelines, compressor flange on the compressor and tighten the flange fastening bolt: bolt tightening torque - 50 Nm (5.0 kgf·m).

Install the drive belt on the compressor pulley.

Attention: install the belt on the compressor pulley from the side of the engine.

Tension the belt by turning bolt 3, fig. 8-70, and tighten the idler roller mounting bolts. Bolt tightening torque — 20...24 Nm (2.0...2.4 kgf·m). The tension of the belt when measured on the upper strand must correspond to the value of the device for determining the frequency of oscillation (173±3) Hz.

Connect the ignition harness connector to the compressor connector.

Install the windshield washer reservoir and connect the ignition harness connector to the washer pump.

Install the engine mudguard, skid plate and noise shield.

Attach terminal "minus" to the battery.

Charge the air conditioning system with refrigerant according to the documentation for the service equipment.

Warning. It is strictly forbidden to carry out refueling through the high pressure pipeline (red service hose) with the engine running and the air conditioner on. To prevent damage to refueling equipment or personal injury, refuel with the engine running and the A/C on only through the low pressure line (blue service hose). All work with refrigerant should be carried out with protective glasses.