Corrosion develops most rapidly in hidden cavities and lower parts of the body when moisture, dirt, salts, and acids enter.

In this regard, during the operation of the car, additional protection of the internal surfaces and hidden cavities of the body is required by applying special anti-corrosion compounds, and in the joints of parts - by applying sealing mastics.

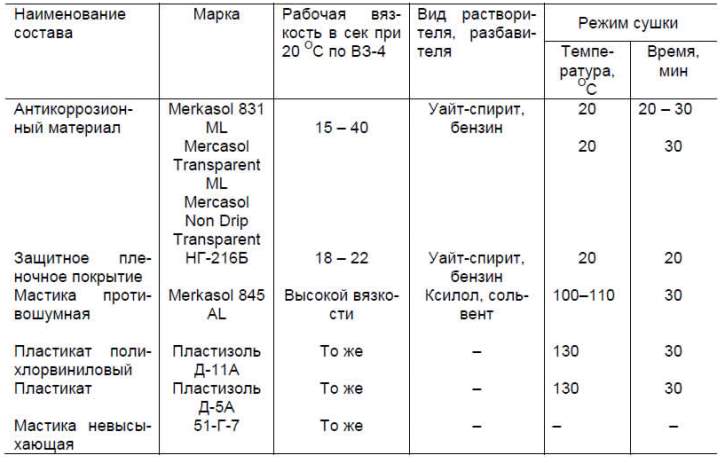

The anti-corrosion treatment materials used are listed in Table 8-1.

Table 8-1. Anti-corrosion compounds for body treatment

The anti-corrosion material Merkasol 831 ML and Mercasol Transparent ML, Non Drip Transparent is used for the treatment of hidden cavities. It is recommended to treat cavities every 2-3 years. The anti-corrosion material allows surface treatment of rusty and wet surfaces.

Protective film coating NG-216B is used to cover parts of the car under the body.

Anti-noise bituminous mastic BPM-2 is used to protect against corrosion of the bottom of the body and to reduce noise. Coating thickness 1.0-1.5 mm.

Plastisol D-11A is used to protect the bottom of the body from corrosion, from abrasive wear and for noise insulation. Coating thickness 1.0-1.2 mm. Plastisol D-11A treated the bottoms of new cars.

Plastisol D-5A is used for sealing welds.

Non-drying mastic 51-G-7 is used to seal body joints.

The anti-corrosion agent is sprayed into the internal cavities by air or airless spraying.

Air spraying requires compressed air with a pressure of 0.5-0.8 MPa (5-8 kgf/cm2), paint spray gun with reservoir, hoses and gun extensions. The best quality of the coating is achieved with airless spraying at a pressure of 4-12 MPa (40-120 kgf/cm2), which allows you to spray materials of significant viscosity.