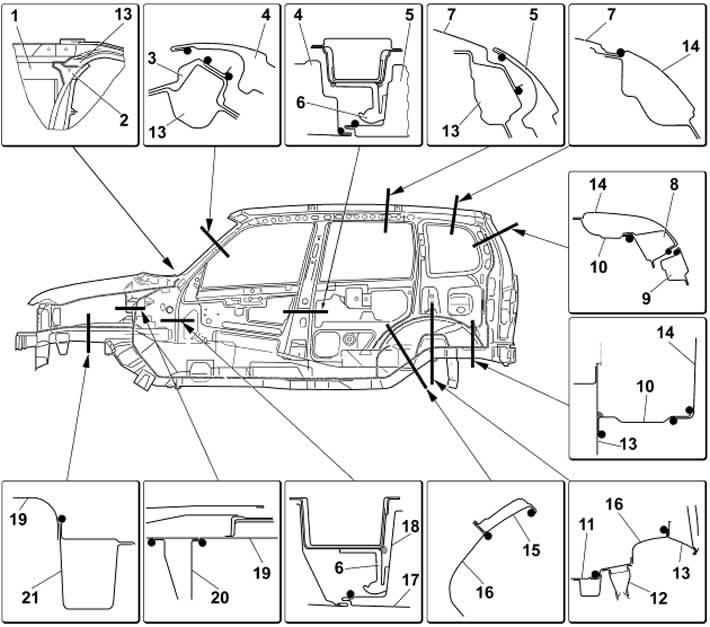

Pic. 8-6. Places for applying sealing mastic (side view):

1 - bulkhead shield amplifier;

2 - wind window frame;

3 - groove;

4 - front door;

5 - back door;

6 - door hinge;

7 - roof panel;

8 - rear pillar;

9 - tailgate;

10 - rear wing extension;

11 - middle floor;

12 - spring support;

13 - rear pillar;

14 - rear wing;

15 - outer arch;

16 - inner arch;

17 - outer door panel;

18 - inner panel of the front door;

19 - mudguard;

20 - bulkhead shield;

21 - front spar.

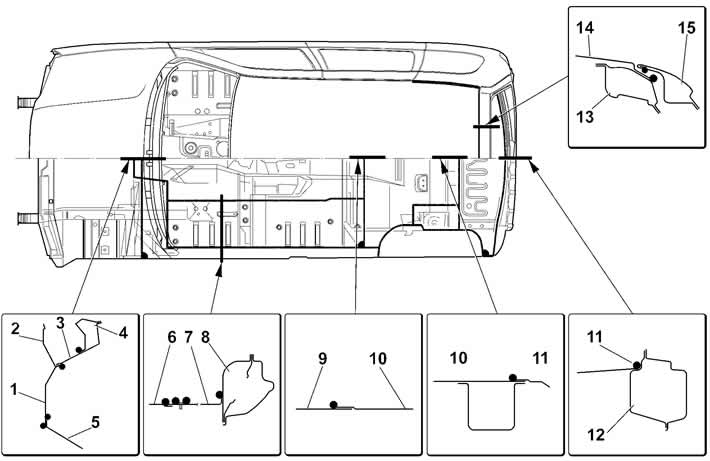

Pic. 8-7. Places for applying sealing mastic (view from above):

1 - front panel;

2 - extension of the bulkhead;

3 - upper reinforcement of the bulkhead;

4 - wind window frame;

5 - front floor;

6 - floor tunnel;

7 - floor panel;

8 - floor threshold;

9 - front floor;

10 - middle floor;

11 - rear floor;

12 - rear cross member;

13 - rear roof beam;

14 - roof panel;

15 - tailgate.

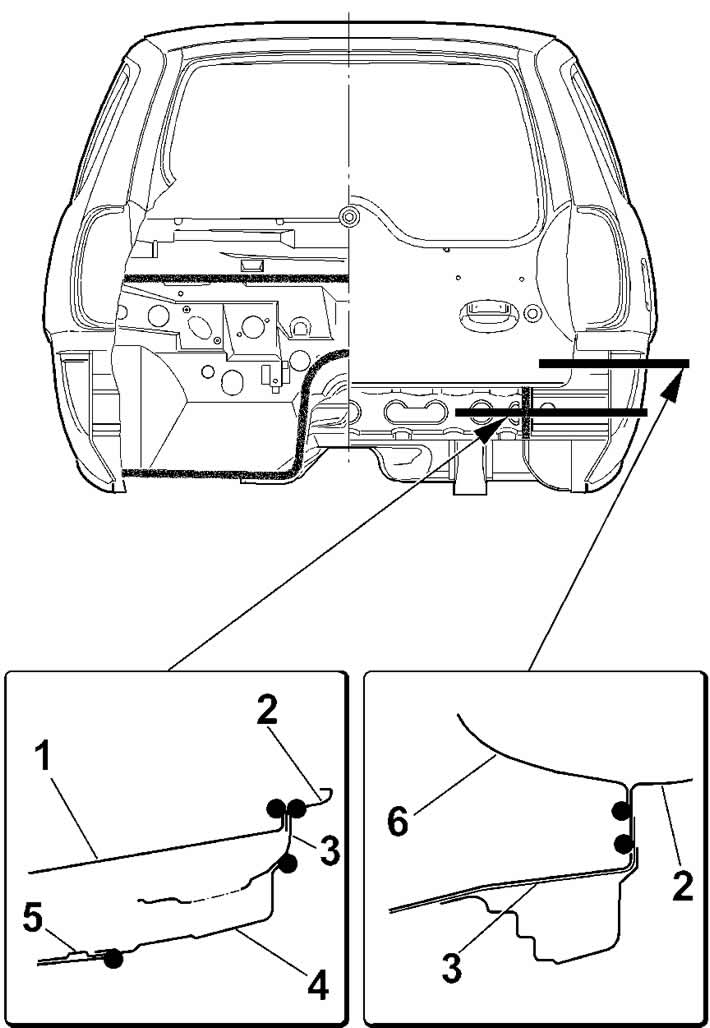

Pic. 8-8. Places for applying sealing mastic (back view):

1 - floor cross member;

2 - sidewall joint;

3 - lining of the rear wing;

4 - rack;

5 - rear cross member;

6 - wheel arch.

When removing and installing seals with metal frames, do not allow the frame to collapse and the formation of corrugations on the seals.

Welded seams are sealed from moisture and dirt ingress with D-4A plastisol. After replacing individual body parts, coat the welds on both sides with D-4A plastisol and apply non-drying mastic 51-G-7 into the corner joints:

- floor sills with front guard (from the salon);

- front guard with front pillar panel;

- connections of the front spars with the radiator frame and the front panel;

- rear floor and rear floor extensions with rear wheel arches, sidewalls and rear cross member.