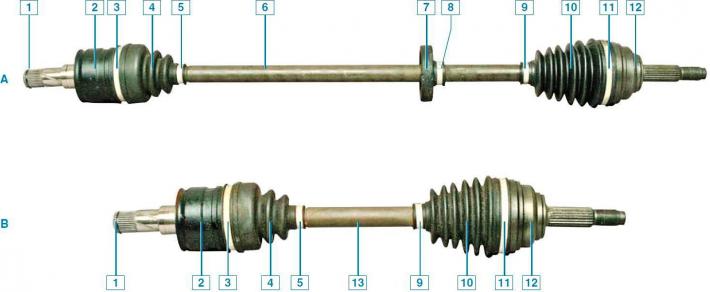

Drives of the right "A" and left "B" wheels: 1 — a lock ring of the internal hinge; 2 - body of the internal hinge; 3 - a large collar for fastening the dirt-protective cover of the inner hinge; 4 — a dirt-protective cover of the internal hinge; 5 — a small collar of fastening of a dirt-protective cover of the internal hinge; 6 - right wheel drive shaft; 7 - damper; 8 — a clamp of fastening of a damper; 9 — a small collar of fastening of a dirt-protective cover of the external hinge; 10 - mud-proof cover of the outer hinge; 11 - a large clamp for fastening the mud-proof cover of the outer hinge; 12 - body of the outer hinge; 13 - left wheel drive shaft

Wheel drives with constant velocity joints (SHRUS) serve to transmit torque from the main gear to the drive wheels at various angles of rotation of the wheels and suspension travel.

The wheel drive consists of inner and outer hinges of equal angular velocities connected to each other by a shaft.

The drive shafts are made of steel bar.

At the ends of the shaft, splines are made on which CV joints are installed.

On the longer shaft of the right drive, a damper is installed.

The hinges of the drives are covered with dirt-protective covers.

The outer hinge consists of a body, separator, cage and six balls, which are placed in the profiled grooves of the body and cage.

In the body and cage of the outer hinge, the grooves are made along the radius, which ensures the angle of rotation of the body relative to the cage up to 42°.

The hinge holder is mounted on the splines of the shaft and is fixed from longitudinal movement by a retaining ring.

The splined shank of the outer hinge housing, at the end of which a thread is cut, is inserted into the front wheel hub and fastened with a bearing nut.

External hinges of drives of the left and right wheels are interchangeable.

Internal drive joint (type "Tripod") provides the possibility of angular movements of the suspension and compensates for the mutual movements of the suspension and the power unit by changing the length of the drive shaft.

On the splined end of the drive shaft, on the side of the internal hinge, a hub with three spikes is installed - a three-spike, on each of the spikes (trunnion) which is a roller with an outer spherical surface, rotating on a needle bearing.

The needle bearing is fixed from displacement along the axis of the stud with a retaining ring located in the groove of the stud.

The three-stud screw is fixed on the drive shaft with a retaining ring.

The mutual movements of the suspension and the power unit are compensated by the movement of the three-stud rollers in the longitudinal grooves of the internal hinge body.

The splined shank of the internal hinge housing is inserted into the side gear installed in the differential box and is fixed in it with an O-ring.

Internal hinges of drives of the left and right wheels are interchangeable.

The outer and inner hinges of the drives have collapsible designs.

Hinge parts are made with high precision.

The inner surface of the hinge body is HDTV hardened.

Balls of one sorting group are installed in the outer hinge.

When assembling the hinge, the balls are selected for each hinge individually, so it is impossible to repair the hinge by replacing parts in a garage or service station.

A worn hinge is replaced only as an assembly.

Before assembly, a special grease for wheel drive joints is placed in the outer and inner hinges before assembly.

The tightness of the hinge - an indispensable condition for its reliable operation - is ensured by rubber mudguards.

The hinge cover is put on the hinge body and the drive shaft and secured with clamps.

When replacing the cover, the clamps of its fastening should also be replaced with new ones.

It is allowed to use only special clamps with a smooth inner surface and no protruding parts.

Replenishment or replacement of lubricant, as well as any other maintenance of the wheel drives during the operation of the vehicle is not required.

The owner of the car only needs to monitor the condition of the protective covers of the hinges and the clamps for their fastening.

A damaged cover must be replaced as soon as possible, since the ingress of dirt into the lubricant causes rapid wear of the hinge parts and failure.