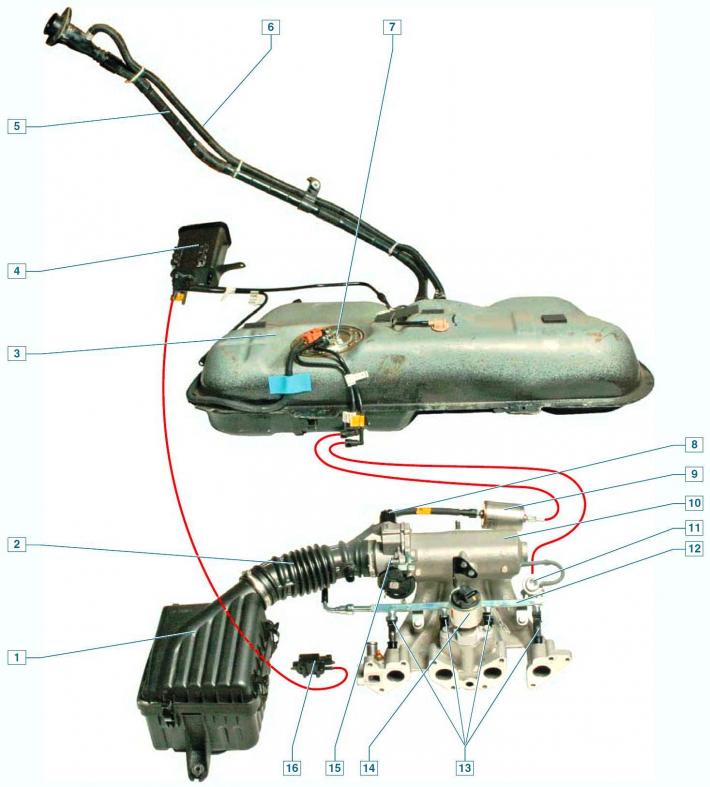

Elements of the engine power system: 1 - air filter; 2 - corrugated hose for supplying air to the throttle assembly; 3 - fuel tank; 4 - adsorber; 5 - filling pipe; 6 - ventilation tube; 7 - fuel module; 8 - idle speed regulator; 9 - fuel filter; 10 - intake manifold; 11 - fuel pressure regulator; 12 - fuel rail; 13 - nozzles; 14 - recirculation valve; 15 - throttle assembly; 16 - adsorber purge valve

Fuel is supplied from a tank installed under the bottom near the rear seat.

The fuel tank consists of two forged steel parts welded together.

The filler neck is connected to the tank with a plastic petrol-resistant filler pipe fixed to the tank branch pipe with a clamp.

Valves are installed in the filler cap to prevent deformation of the tank when the pressure inside it changes.

The upper parts of the filling pipe and the fuel tank are connected by a plastic ventilation tube, which serves to vent the air forced out of the tank when refueling.

A fuel module is installed in the tank, which includes a fuel pump and a fuel level indicator sensor with a fuel reserve indicator lamp resistor.

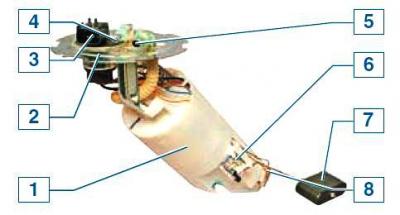

Fuel module: 1 — module case; 2 — module cover; 3 — a socket of a plait of wires of a control system of the engine; 4 - fitting of the drain line; 5 - fitting of the discharge line; 6 - fuel gauge sensor; 7 - float sensor fuel gauge; 8 — the resistor of a control lamp of a reserve of fuel

To access the fuel module under the rear seat cushion in the bottom of the car there is a hatch closed with a lid.

The fuel gauge sensor sends signals to the gauge located in the instrument cluster.

The fuel pump is located inside the fuel module housing.

It is very difficult to replace the pump separately, therefore, if it fails, it is advisable to replace the pump in an authorized service or it is necessary to replace the fuel module assembly.

From the pump, pressurized fuel is supplied to the fuel filter.

Fuel filter

Fine fuel filter - non-separable, in a metal case, with a paper filter element.

The filter is fixed in the engine compartment on the front panel.

An arrow is marked on the filter housing, which must coincide with the direction of fuel movement.

After the filter, the fuel enters the fuel rail.

Fuel rail assembly with injectors and fuel pressure regulator

The fuel rail is a metal tube with injectors mounted on it.

The ramp is attached to the intake manifold with two bolts.

The fuel pressure regulator is located on the left side of the rail.

Fuel pressure control

The fuel pump creates excess pressure in the system that exceeds the operating pressure of the fuel injectors.

The pressure regulator ensures that excess fuel is discharged through the drain line into the fuel tank.

The pressure regulator is a fuel valve connected to a spring loaded diaphragm.

The valve is closed by spring force.

The diaphragm divides the regulator cavity into two isolated chambers - "fuel" and "air".

"Air" is connected by a vacuum hose to the intake manifold, and "fuel" - directly to the ramp cavity.

When the engine is running, the vacuum, overcoming the resistance of the spring, tends to retract the diaphragm, opening the valve.

On the other hand, fuel exerts pressure on the diaphragm, also compressing the spring.

As a result, the valve opens, and part of the fuel is bled through the drain line back into the tank.

When you press the "gas" pedal, the vacuum behind the throttle decreases, the diaphragm closes the valve under the action of the spring - the fuel pressure increases.

If the throttle is closed, the vacuum behind it is maximum, the diaphragm pulls the valve more strongly - the fuel pressure decreases.

The pressure regulator is non-separable and must be replaced if it fails.

The nozzle is fixed on the ramp with a metal locking bracket and sealed in the ramp and intake manifold with rubber rings.

O-ring nozzle

At the outlet of the nozzle there is a sprayer through which fuel is injected into the inlet manifold.

The injectors are controlled by an electronic control unit.

In the event of an open or short circuit in the injector winding, the latter should be replaced.

If the nozzles are clogged, they can be washed without dismantling at a special service station stand.

Air enters the engine through the air intake, resonator, air filter, corrugated rubber hose, throttle assembly and intake manifold.

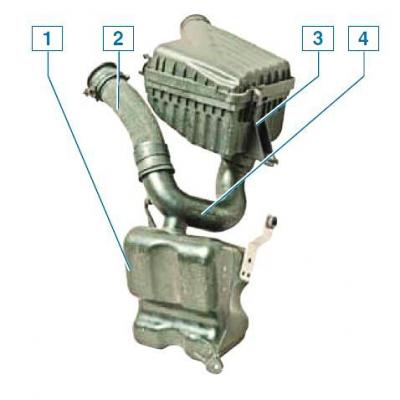

Elements for supplying air to the throttle assembly: 1 - resonator; 2 - air intake; 3 - air filter; 4 - resonator tee

The air filter with a replaceable paper element cleans the intake air, while the resonator dampens intake air noise.

The air intake and resonator are located under the right front fender, while the air filter is located in the front of the engine compartment on the right.

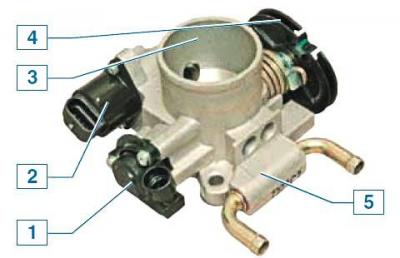

The throttle assembly is attached to the intake manifold and is a throttle body (with channels made in it), which has an idle speed controller and a throttle position sensor.

Throttle assembly: 1 - throttle position sensor; 2 - idle speed regulator; 3 - body; 4 - damper drive sector; 5 - heating block

To prevent freezing of the throttle assembly at low temperatures and high ambient humidity, a heating unit is built into the assembly, through which the cooling system fluid circulates.

When you press the "gas" pedal, the throttle valve opens, changing the amount of air entering the engine (fuel supply is calculated by the control unit depending on the air flow).

When the engine is idling (throttle closed) The ECU controls the air supply with the idle air control.

idle speed controller

The idle speed controller is a stepper motor that moves the valve.

Locking element of the valve (needle) changes the flow area of the channel and provides regulation of the air flow bypassing the throttle valve.

To increase the idle speed of the crankshaft, the electronic unit sends a control signal to open the valve, increasing the air supply bypassing the throttle, and, conversely, to reduce the speed, a command is given to close the valve.

In addition to controlling the idle speed of the crankshaft, the control unit using the regulator reduces the toxicity of exhaust gases - when the engine is braked, the throttle closes abruptly, in this case the regulator increases the air supply bypassing the throttle, resulting in a lean fuel mixture.

This contributes to the reduction of hydrocarbon and carbon monoxide emissions.

The idle speed regulator is non-separable and must be replaced if it fails.

After passing the throttle assembly, air enters the intake manifold.

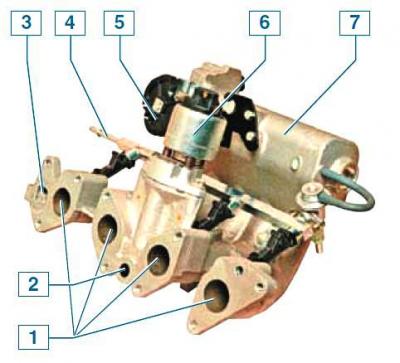

Intake manifold assembly: 1 - channels for supplying air to the cylinder head; 2 - channel for supplying exhaust gases from the cylinder head to the recirculation valve; 3 - coolant channel; 4 - fuel rail with injectors; 5 - throttle assembly; 6 - recirculation valve; 7 - receiver

Channel of selection of the fulfilled gases from a head of the block of cylinders (intake manifold removed)

From the common cavity of the intake manifold - receiver, air is supplied through four separate channels to the intake channels of the cylinder head.

In order for the filling of the engine cylinders with air to be the same, the air supply channels are made approximately the same length.

To reduce exhaust emissions (by reducing the formation of nitrogen oxides) an exhaust gas recirculation system is provided.

The principle of its operation is to reduce the combustion temperature of the fresh air-fuel mixture in the engine cylinders by diluting it with exhaust gases taken from the exhaust channel of the cylinder head.

The system consists of a recirculation valve attached to the intake manifold and passages in the intake manifold and cylinder head.

recirculation valve

Depending on the engine operating mode, according to the signals of the electronic control unit, the valve regulates the amount of exhaust gases entering the intake manifold for afterburning.

The power system includes a fuel vapor recovery system, including an adsorber installed under the bottom of the car near the rear right wheel, and an adsorber purge solenoid valve attached to the lower generator bracket.

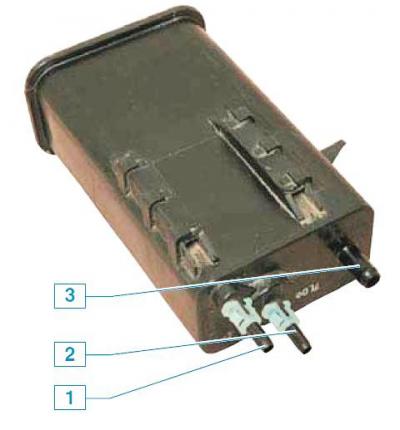

Adsorber: 1 - fitting of the pipe for removing fuel vapors from the adsorber to the solenoid valve; 2 - fitting of the pipe for supplying fuel vapor from the tank to the adsorber; 3 - air supply fitting

Fuel vapors from the tank enter the adsorber (activated carbon container) through the fitting labeled "TANK", where they accumulate while the engine is not running.

The second fitting of the canister with the inscription "PURGE" is connected by a tube to the canister purge solenoid valve, and the third one with the inscription "AIR" is connected to the atmosphere.

When the engine is stopped, the purge solenoid valve is closed, in which case the adsorber does not communicate with the intake manifold.

When the engine is running, the electronic unit, controlling the solenoid valve, purges the adsorber with fresh air due to the vacuum in the intake manifold.

Gasoline vapors are mixed with air and discharged into the intake manifold and then into the engine cylinders.

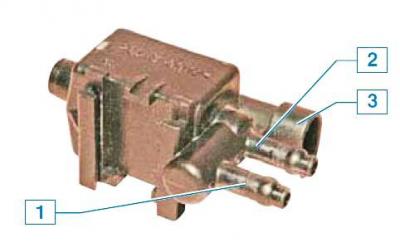

Canister purge solenoid valve: 1 - fitting of the tube connecting the valve with the adsorber; 2 - fitting of the tube connecting the valve to the intake manifold; 3 - electrical connector