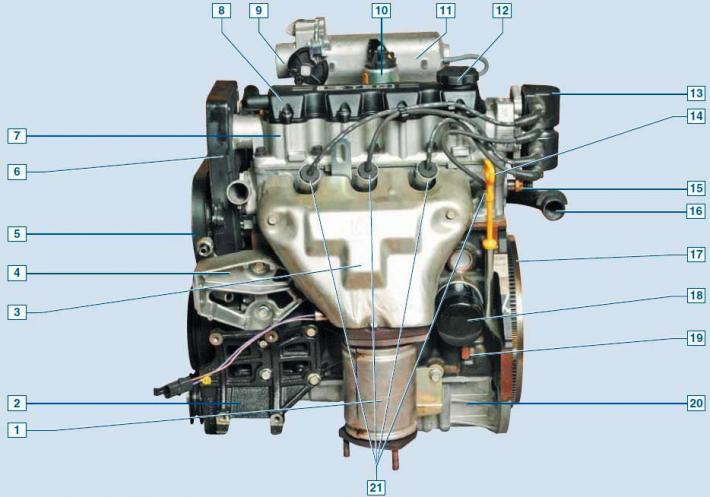

power unit (front view of the car): 1 - catalytic converter of exhaust gases; 2 — an arm of the compressor of the conditioner; 3 - heat-shielding casing of the exhaust manifold; 4 - bracket for the right support of the power unit; 5 - generator drive belt; 6 - rear cover of the timing drive; 7 - cylinder head; 8 - cylinder head cover; 9 - throttle assembly; 10 - recirculation valve; 11 - intake manifold; 12 - oil filler cap; 13 - ignition coil; 14 - oil level indicator (oil dipstick); 15 - coolant temperature sensor; 16 - inlet pipe of the coolant pump; 17 - flywheel; 18 - oil filter; 19 - cylinder block; 20 - oil pan; 21 - a tip of a high-voltage wire

The engine is gasoline, four-stroke, four-cylinder, in-line, eight-valve, with an overhead camshaft. Located transversely in the engine compartment. The order of operation of the cylinders: 1-3-4-2, counting - from the auxiliary drive pulley.

Power system - phased distributed fuel injection (Euro-3 toxicity standards). An engine with a gearbox and clutch form a power unit - a single unit mounted in the engine compartment on three elastic rubber-metal supports. The right support is attached to the bracket located on the front wall of the cylinder block, and the left and rear - to the gearbox housing brackets.

Right side of the engine (in the direction of the car) located: timing gear drive and coolant pump (toothed belt), generator drive and power steering pump (V-ribbed belt), A/C compressor drive (V-belt), oil pump, thermostat, crankshaft position sensor.

On the left are: the ignition coil and the coolant temperature sensor.

Front: Exhaust manifold, oil filter, oil gauge, spark plugs, A/C compressor (bottom right).

Rear: intake manifold with throttle assembly, fuel rail with injectors, exhaust gas recirculation valve, generator, starter, low oil pressure sensor, canister purge valve, phase sensor, knock sensor, coolant pump feed pipe, coolant temperature indicator sensor.

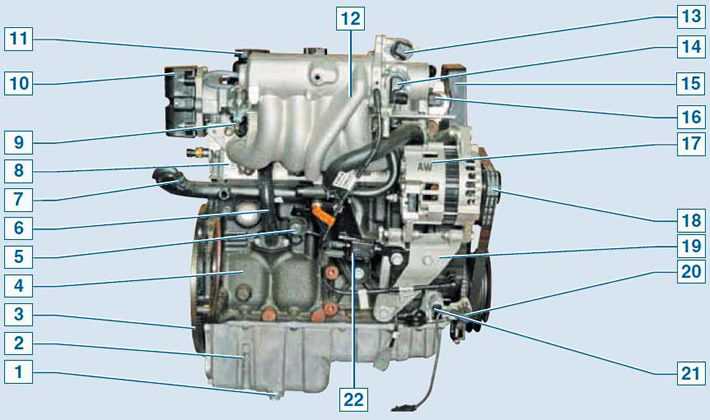

Engine (rear view of the car): 1 - oil drain plug; 2 - oil pan; 3 - flywheel; 4 - cylinder block; 5 - knock sensor; 6 - crankcase ventilation pipe; 7 - inlet pipe of the coolant pump; 8 - cylinder head; 9 - fuel pressure regulator; 10 - ignition coil; 11 - oil filler cap; 12 - intake manifold; 13 - idle speed regulator; 14 - throttle position sensor; 15 - rear cover of the timing drive; 16 - phase sensor; 17 - generator; 18 - generator drive belt; 19 - generator bracket; 20 - crankshaft position sensor; 21 - low oil pressure sensor; 22 - adsorber purge valve

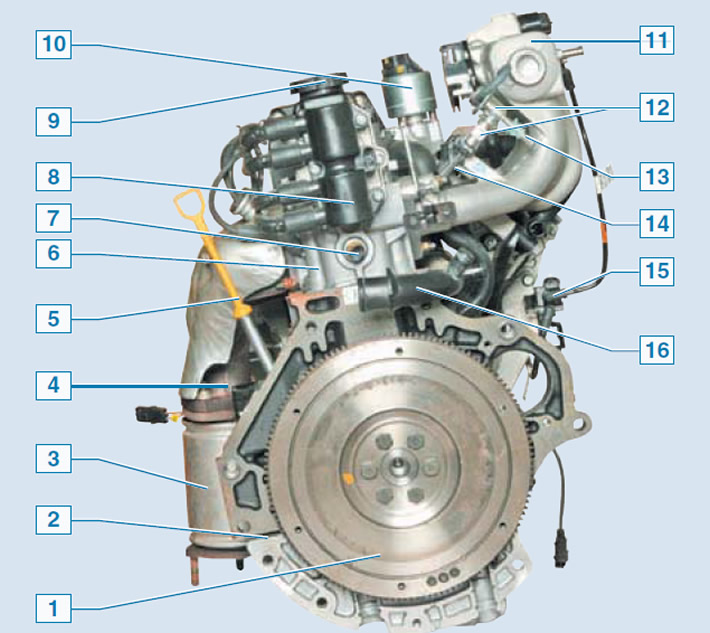

Engine (left side view of the car): 1 - flywheel; 2 - cylinder block; 3 - catalytic converter; 4 - exhaust manifold; 5 - oil level indicator; 6 - cylinder head; 7 - coolant temperature sensor; 8 - ignition coil; 9 - oil filler cap; 10 - exhaust gas recirculation valve; 11 - intake manifold; 12 - fuel pressure regulator; 13 - fuel rail; 14 - nozzle; 15 - adsorber purge valve; 16 - inlet pipe of the coolant pump

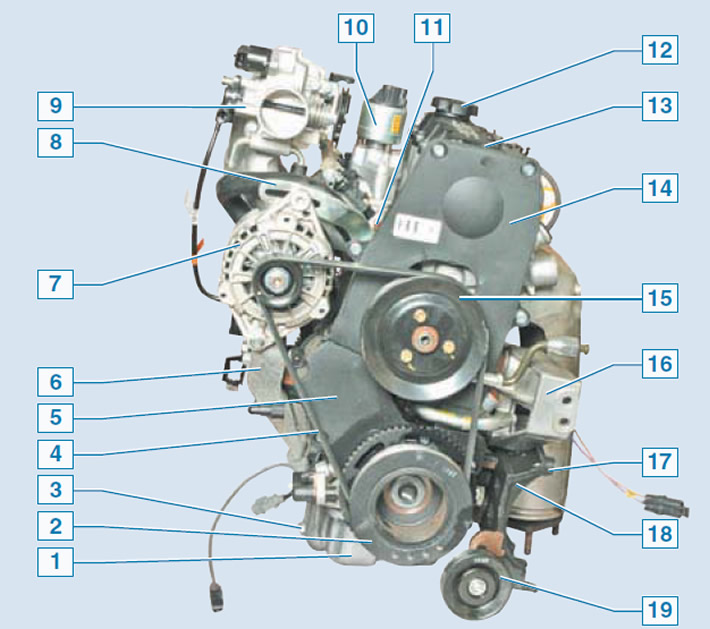

Engine (right side view of the car): 1 - oil pan; 2 - auxiliary drive pulley; 3 - oil drain plug; 4 - generator drive belt; 5 - lower cover of the timing drive; 6 - generator bracket; 7 - generator; 8 - tension bar of the generator drive belt; 9 - throttle assembly; 10 - recirculation valve; 11 - coolant temperature indicator sensor; 12 - oil filler cap; 13 — a cover of a head of the block of cylinders; 14 — the top cover of the timing drive; 15 - power steering pump pulley; 16 - bracket for the right support of the power unit; 17 - catalytic converter; 18 — an arm of the compressor of the conditioner; 19 — a tension roller of a belt of a drive of the compressor of the conditioner

The cylinder block is cast iron, the cylinders are bored directly into the block. The cooling jacket and oil channels are made in the body of the cylinder block.

In the lower part of the cylinder block there are five crankshaft main bearing supports with removable covers, which are attached to the block with special bolts. Holes in the cylinder block for bearings are machined with covers installed, so the covers are not interchangeable and are marked on the outer surface with numbers (account from the timing pulley).

The crankshaft is made of ductile iron, with five main and four connecting rod journals. The shaft is equipped with eight counterweights cast integrally with it. Inserts of main and connecting rod bearings of the crankshaft are steel, thin-walled, with an anti-friction coating. The main and connecting rod journals of the crankshaft connect the channelslocated in the body of the shaft. The axial movement of the crankshaft is limited by two liners with thrust collars of the third main bearing. At the front end (sock) crankshaft mounted: Timing gear pulley (timing) and accessory drive pulley. A flywheel is attached to the crankshaft flange with six bolts. It is cast iron and has a pressed steel ring gear for starting the engine with a starter.

Connecting rods - forged steel, I-section. With their lower heads, the connecting rods are connected through liners to the connecting rod journals of the crankshaft, and the upper heads are connected through piston pins to the pistons.

Pistons are made of aluminum alloy. The hole for the piston pin is offset relative to the axis of symmetry of the piston by 0.7 mm to the rear wall of the cylinder block. Three grooves for piston rings are machined in the upper part of the piston. The two upper piston rings are compression rings, and the lower one is oil scraper.

Piston pins steel, tubular section. In the holes of the pistons, the fingers are installed with a gap, and in the upper heads of the connecting rods - with an interference fit (pressed in).

The cylinder head is cast from aluminum alloy, common to all four cylinders.

The head is centered on the block with two bushings and fastened with ten bolts.

A gasket is installed between the block and the cylinder head. On the front side of the cylinder head there are exhaust ports, and on the rear side there are intake ports. The spark plugs are screwed into threaded holes in the cylinder head.

Seats and valve guides are pressed into the cylinder head. The valve closes under the action of one spring. Its lower end rests on a washer, and its upper end rests on a plate held by two crackers. The crackers folded together have the shape of a truncated cone, and on their inner surface there are beads that enter the grooves on the valve stem. Actuates the valves on the camshaft. Cast iron camshaft, rotates on five bearings (bearings) in an aluminum bearing housing that is attached to the top of the cylinder head. Camshaft drive - toothed belt from the crankshaft.

The valves are actuated by the camshaft cams through pressure levers, which are supported by one shoulder on the hydraulic clearance compensators, and by the other through the guide washers - on the valve stems. The use of hydraulic compensators in the valve drive reduces the noise of the gas distribution mechanism, and also eliminates its maintenance.

Engine lubrication - combined. Under pressure, oil is supplied to the main and connecting rod bearings of the crankshaft, pairs of "support - camshaft journal" and hydraulic compensators. The pressure in the system is created by an oil pump with internal gears and a pressure reducing valve. The oil pump is attached to the cylinder block on the right side. The drive gear of the pump is mounted on two flats of the toe of the crankshaft. The pump takes oil from the oil pan through the oil receiver and delivers it through the oil filter to the main line of the cylinder block, from which oil channels depart to the main bearings of the crankshaft and the channel for supplying oil to the cylinder head.

The oil filter is full-flow, non-separable, equipped with bypass and anti-drain valves. By spraying, oil is supplied to the pistons, cylinder walls and camshaft lobes. Excess oil flows through the channels of the cylinder head into the oil pan.

The crankcase ventilation system is forced, closed type. The system is designed to reduce the emission of harmful substances from the engine crankcase into the atmosphere. Due to the vacuum in the intake manifold, gases from the crankcase through the ventilation hose enter under the cylinder head cover. After passing through the oil separator located in the block head cover, crankcase gases are cleaned of oil particles and enter the engine intake tract through the hoses of two circuits: the main and the idle circuit, and then into the cylinders. Through the main circuit hose, crankcase gases are discharged at partial and full engine load modes into the space in front of the throttle valve. Through the hose of the idle circuit, gases are discharged into the space behind the throttle valve, both in partial and full load modes, and in idle mode.

Engine management, power supply, cooling and exhaust systems are described in the relevant chapters.

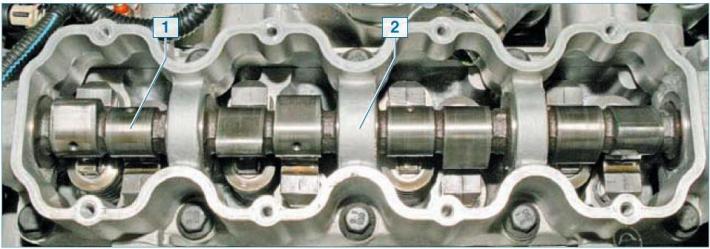

cylinder head (head cover removed): 1 - camshaft; 2 - camshaft bearing housing

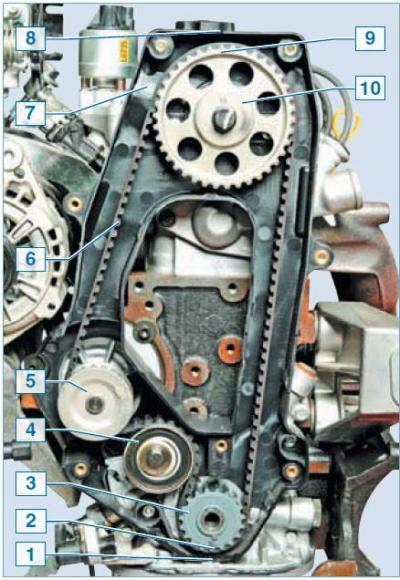

Timing gear drive: 1 - mark on the back cover of the timing drive; 2 - mark on the gear pulley of the crankshaft; 3 — a gear pulley of a cranked shaft; 4 - tension roller; 5 - toothed pulley of the coolant pump; 6 - belt; 7 — a back cover of a drive; 8 - mark on the back cover of the timing drive; 9 - mark on the camshaft pulley; 10 — a gear pulley of a camshaft

Reference

Counterweights. Made on the continuation of the cheeks of the crankshaft of the engine. Counterweights are designed to balance the forces and moments of inertia arising from the movement of the crank mechanism during engine operation.

Channels. Made in the body of the crankshaft. They serve not only to supply oil from the main to the connecting rod bearings of the shaft, but also for centrifugal cleaning of engine oil from solid particles and deposits during the rotation of the crankshaft.

Flywheel. Provides the removal of the engine pistons from the top and bottom dead centers and more uniform rotation of the crankshaft in idle mode. Makes it easier to start the engine and its operation when starting the car.

Piston rings. Compression rings prevent the breakthrough of gases from the cylinder into the crankcase and contribute to the removal of heat from the piston to the cylinder. The oil scraper ring removes excess oil from the cylinder walls as the piston moves.

Hydraulic compensator. Selects the gap between the camshaft cam and the valve push lever by moving the hydraulic compensator plunger under the action of its spring and supplying engine oil under pressure when the engine is running.