It must be borne in mind that the failure of the timing belt (broken or sheared teeth) can lead to sticking of valves into pistons due to a mismatch of the angles of rotation of the crankshaft and camshafts and, as a result, to expensive engine repairs.

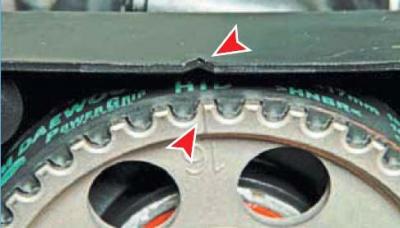

The surface of the toothed part of the belt must not have folds, cracks, undercutting of the teeth and delamination of the fabric from the rubber. The reverse side of the belt should not have wear, exposing the cord threads, and signs of burning.

On the end surfaces of the belt there should be no delaminations and fraying. The belt must also be replaced if traces of oil are found on it (before replacing the belt, the cause of its oiling must be eliminated) or when replacing a failed idler roller and coolant pump.

To check the condition of the timing belt..

... with a "10" head, we unscrew the four bolts securing the upper front cover of the timing drive.

Pulling the front cover away from the back, check the condition of the belt.

To replace the timing belt, remove the air filter (see Removing the air filter). Remove the right front wheel. Remove the air conditioning compressor drive belt (see Check of a condition and replacement of a belt of a drive of the compressor of the conditioner). Remove the alternator drive belt (see Replacing the alternator drive belt). For clarity, we show the operations for replacing the timing belt on a dismantled engine.

With the "10" head, we unscrew the four bolts securing the upper front cover of the timing drive..

... and remove the cover.

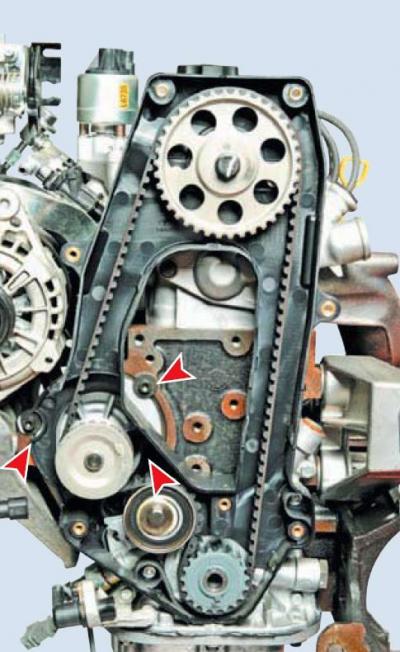

With a high "17" head, we turn the crankshaft clockwise for the bolt securing the auxiliary drive pulley..

... until the mark on the camshaft pulley aligns with the slot on the rear timing cover.

At the same time, the mark on the accessory drive pulley (located between the 5th and 6th teeth, counted clockwise from the platform without teeth) should be opposite the pointer on the lower front cover of the timing drive.

Removing the power steering pump (see Removing the power steering pump).

With a high "17" head, we unscrew the bolt securing the auxiliary drive pulley. To keep the crankshaft from turning, the assistant must engage fifth gear and depress the brake pedal.

Remove bolt and washer..

... and remove the accessory drive pulley.

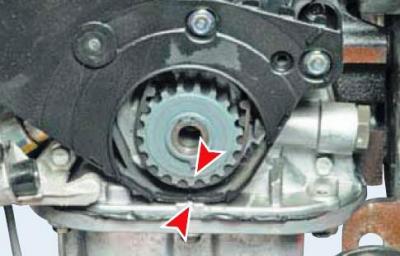

Once again, we check the coincidence of the alignment mark on the camshaft pulley with the slot on the rear cover of the timing drive. With correctly installed phases of the gas distribution mechanism..

... the mark on the crankshaft sprocket should be opposite the slot on the rear timing cover.

With the "10" head, we unscrew the three bolts securing the lower front timing cover..

... and remove the cover.

We loosen the tension of the timing belt by turning the spring-loaded movable plate of the tension roller clockwise with a screwdriver until the hole in it is aligned with the hole in the roller bracket..

... and insert a pin with a diameter of 4.0–4.5 mm into both holes (e.g. drill shank or screw).

We remove the belt from the toothed pulleys of the camshaft and crankshaft and the coolant pump.

With the "12" head, we unscrew the bolt of the tension roller..

…and filming a video.

Install the new roller in reverse order.

Before installing the auxiliary drive belt, we make sure that the alignment marks on the toothed pulleys of the crankshaft and camshafts and the corresponding slots on the rear timing cover are aligned. In this position, we put the belt on the toothed pulley of the crankshaft. We start the rear branch of the belt by the tension roller and put the belt on the pulleys of the coolant pump and camshaft, eliminating the sagging of the front branch of the belt.

We take out the pin from the holes of the movable bar and the tension roller bracket.

We install the auxiliary drive pulley and wrap the bolt of its fastening. Turn the crankshaft by the pulley bolt two turns clockwise. If at the same time…

... pointer 1 of the movable strip of the tension roller is aligned with the notch 2 on the bracket (for clarity, shown on the removed tension roller), then the timing belt tension is normal. If not, we carry out an additional adjustment of the belt tension by turning the coolant pump.

For this…

... with a "5" hexagon, we loosen the tightening of the three screws securing the coolant pump.

The timing belt tension changes when the pump housing is rotated in the cylinder block seat.

You can turn the pump by the "41" hexagon on its body.

To rotate the pump from a metal plate, you can make a fixture yourself. Set up the device like this..

... so that its "legs" tightly cover the hexagon of the pump and use the device as a lever.

The hexagon pump can also be turned with sliding pliers.

We turn the pump counterclockwise until the index of the movable plate of the tension roller is aligned with the notch on the roller bracket.

In this position, tighten the screws securing the coolant pump. We turn the crankshaft clockwise two turns and check the coincidence of the alignment marks of the shafts. If necessary, repeat the operation. We make sure that there are no leaks from under the coolant pump. If required, replace the pump housing O-ring (see Removing the coolant pump).

Further assembly is carried out in the reverse order.

We fill the power steering hydraulic drive with working fluid and remove air from it. We bring the coolant level to normal.