... disconnect the block of the wiring harness of the engine control system from the speed sensor.

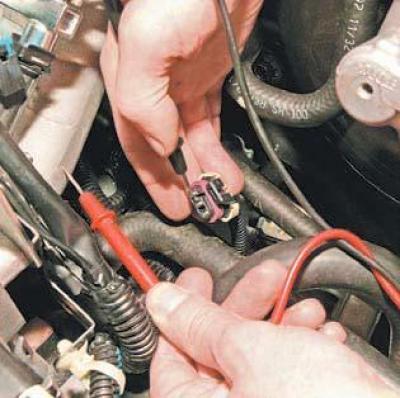

We connect the tester probes to the terminals "A" and "C" of the block of the wiring harness.

With the ignition on, the voltage must be equal to the voltage of the on-board network.

Similarly, we measure the voltage between the terminals "A" and "B".

With the ignition on and the on-board network voltage of 12.5–13.0 V, the device should record a voltage of 10.5–11.0 V.

If the voltage value is not correct, check the health of the circuit (open and short to ground) between terminal "B" of the block of the wiring harness of the engine management system and terminal "K6" of the block of the ECU harness.

We also check the integrity of the fuse F14 (15A) mounting block located in the cabin, and the health of the circuit (open and short to ground) between terminal "C" of the block of the harness of the engine management system and the mounting block.

By connecting the tester probes to terminal "A" of the block and the "mass" of the engine, we measure the resistance of the "mass" circuit.

With a good sensor ground circuit, the device should detect a resistance of less than 1 ohm.

The reason for the increased resistance may be an unreliable connection in the pads connected to the sensor or to the computer.

If the sensor circuits are OK, the computer is faulty.

To check the speed sensor, dismantle it (see Removing the vehicle speed sensor) and connect the wiring harness to the sensor.

From the side of the input of the wires into the block, we insert a piece of wire into the socket corresponding to the output "B" so that there is contact between it and the output.

Slowly rotating the sleeve of the speed sensor, the tester measures the voltage between the output "B" and "ground".

With the ignition on, the device should record regularly changing voltage values I (below 0.5 V) and II (above 10.0 V).

We replace the faulty speed sensor with a new one.