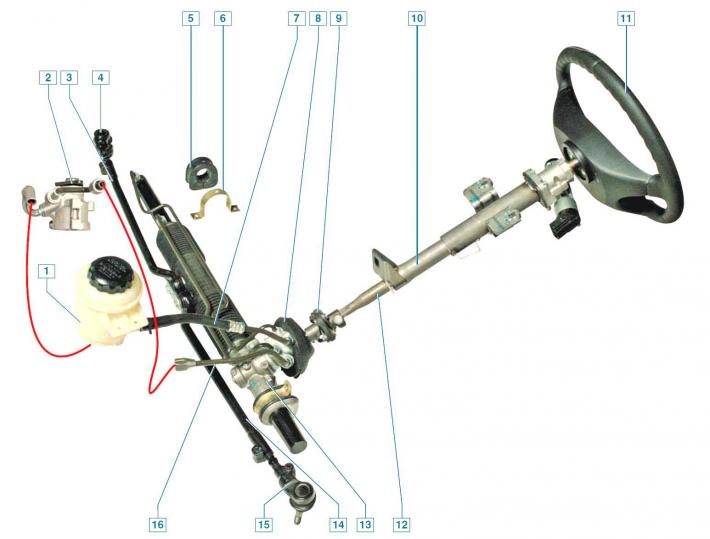

Power steering elements: 1 - power steering reservoir; 2 - power steering pump; 3 — an internal tip of the right steering draft; 4 - outer tip of the right steering rod; 5 — the right support of the steering mechanism; 6 — a bracket of a support of the steering mechanism; 7 - drain hose; 8 - steering gear seal; 9 - elastic coupling; 10 - steering column; 11 - steering wheel; 12 - steering shaft; 13 — steering mechanism; 14 — an internal tip of the left steering draft; 15 - outer tip of the left tie rod; 16 - discharge line

Steering gear with rods assy: 1 - right steering rod; 2 - connecting tubes of the hydraulic booster; 3 - protective cover; 4 – a locking plate of bolts of fastening of steering rods; 5 - pinion shaft; 6 – a case of the steering mechanism; 7 – the left steering draft

Steering of the car - with a safety steering column, which prevents the steering wheel from moving towards the driver when the steering mechanism moves back in a frontal collision.

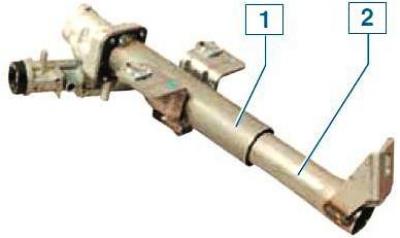

This is ensured by the design of the steering column, consisting of two metal pipes.

The lower inner tube is installed in the outer one through plastic split rings, which ensure their tight connection.

However, when shock overloads are exceeded, for example, when a car collides with an obstacle, the connection of the pipes allows them to move relative to each other.

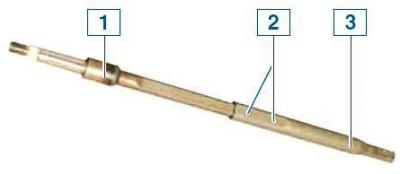

The design of the steering shaft also allows you to change (shorten) its length in a vehicle collision as a result of cutting off two plastic pins connecting the two parts of the shaft.

The rack-and-pinion steering mechanism is fixed in the engine compartment on the front end shield of the body with two brackets through rubber supports.

Steering column: 1 - upper outer pipe; 2 - lower inner tube

The steering box is cast from aluminum alloy.

In the crankcase of the steering mechanism, a drive gear is installed on bearings, made integral with the shaft (pinion shaft), which is engaged with the rail.

The rail is pressed against the gear by a spring through a stop, which is sealed in the crankcase with a rubber ring.

The spring rests on the adjusting plug.

The adjusting plug is held against loosening by a lock nut.

Steering rods are attached to the rack with bolts that pass through the base plate, rubber-metal hinges of the inner tips and the rack slider.

The bolts are secured against loosening by a locking plate fitted over the bolt heads.

The steering drive consists of two steering rods connected by ball joints with swing arms welded to the shock absorber struts of the front suspension.

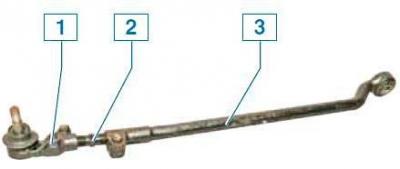

Each rod consists of an inner tip, an outer tip and an adjusting screw.

At the ends of the adjusting screw, an external thread is cut in the opposite direction (right and left), a turnkey hexagon is made in the middle of the screw.

The length of the steering rod is changed by turning the adjusting screw, which is screwed into the threaded holes of the inner and outer tips, with the bolts of the terminal connections of the tips loosened.

Left tie rod: 1 - outer tip with a ball joint; 2 - adjusting screw; 3 - inner tip

This allows you to adjust the convergence of the steered wheels of the car.

After completing the adjustment, the terminal connections of the tie rod ends are tightened with bolts.

The ball joint of the outer rod end has a non-separable design and does not require replenishment of the lubricant supply, which is embedded inside for the entire service life.

The outer and inner tips of the right and left steering rods are not interchangeable.

The steering column shaft is attached to the drive gear of the steering mechanism through an elastic coupling.

Steering Shaft: 1 - the upper part of the shaft; 2 - plastic pins; 3 - the lower part of the shaft

Elastic coupling

A steering wheel is mounted on the splines in the upper part of the shaft, secured with a nut.

The steering column is attached to the brackets of the bulkhead: in the front part - with one nut, in the rear part - with two nuts.

The hydraulic booster of a steering is built in the steering mechanism.

The hydraulic booster system includes: a vane pump, a reservoir for working fluid, pipes for drain and discharge lines.

The pump is bolted to the engine block on the right side and is driven by a belt from the engine crankshaft pulley.

The working fluid from the tank is supplied by a pump under high pressure to the switchgear (distributor), located in the steering gear housing and mechanically connected to the steering shaft.

A hydraulic cylinder piston is fixed on the gear rack of the steering mechanism.

When the steering wheel is turned, the distributing device connects one of the hydraulic cylinder chambers to the pump discharge line, and the other chamber to the drain.

In this case, the piston of the hydraulic cylinder, due to the pressure difference of the working fluid, moves the rack to the left or right and through the steering rods and rotary levers turns the steered wheels of the vehicle.

If the hydraulic booster fails, the ability to drive the car remains, but the effort on the steering wheel increases.

The power steering reservoir is installed in the engine compartment on a bracket welded to the left mudguard cup.

To control the liquid level, the translucent body of the tank is marked with MIN and MAX marks.